3/11

Siemens Building Technologies CC1N7418en

HVAC Products 08.04.2004

Electrical connection of ionization probe

It is important to achieve practically disturbance- and loss-free signal transmission:

• Never run the detector cable together with other cables

– Line capacitance reduces the magnitude of the flame signal

– Use a separate cable

• Observe the permissible length of the detector cable (refer to «Technical data»)

• The ionization probe is not protected against electric shock hazard

• Locate the ionization probe such that the ignition spark cannot arc over (risk of

electrical overloads)

• Always run the high-voltage ignition cables separate from the unit and other cables

while observing the greatest possible distances

• The insulation resistance between ionization probe and ground must be a minimum

of 50 MΩ, even after a large number of operating hours.

Prerequisite for this is not only high quality heat-resistant insulation of the cable,

but also of the ionization probe itself (ceramic holder!)

• A soiled ionization probe holder offers favorable conditions for surface leakage cur-

rents which reduce the magnitude of the flame signal

• The burner (as the counter-electrode) must be correctly earthed, or else no ioniza-

tion current will flow

Earthing the boiler alone does not suffice!

• The connection diagrams shown apply to burner controls with earthed neutral con-

ductor. In the case of ionization current supervision in networks with nonearthed

neutral conductor, terminal 2 must be connected to the earth conductor via an RC

unit (part no. ARC 4 668 9066 0). In that case, it must be made certain that the

relevant national safety regulations are complied with (e.g. electric shock hazard

protection), since AC 230 V / 50 Hz mains voltage results in a leakage current of

2.7 mA

Commissioning notes

• Prior to commissioning, check to ensure that wiring is in an orderly state

• When commissioning the plant or when doing maintenance work, make the follow-

ing safety checks:

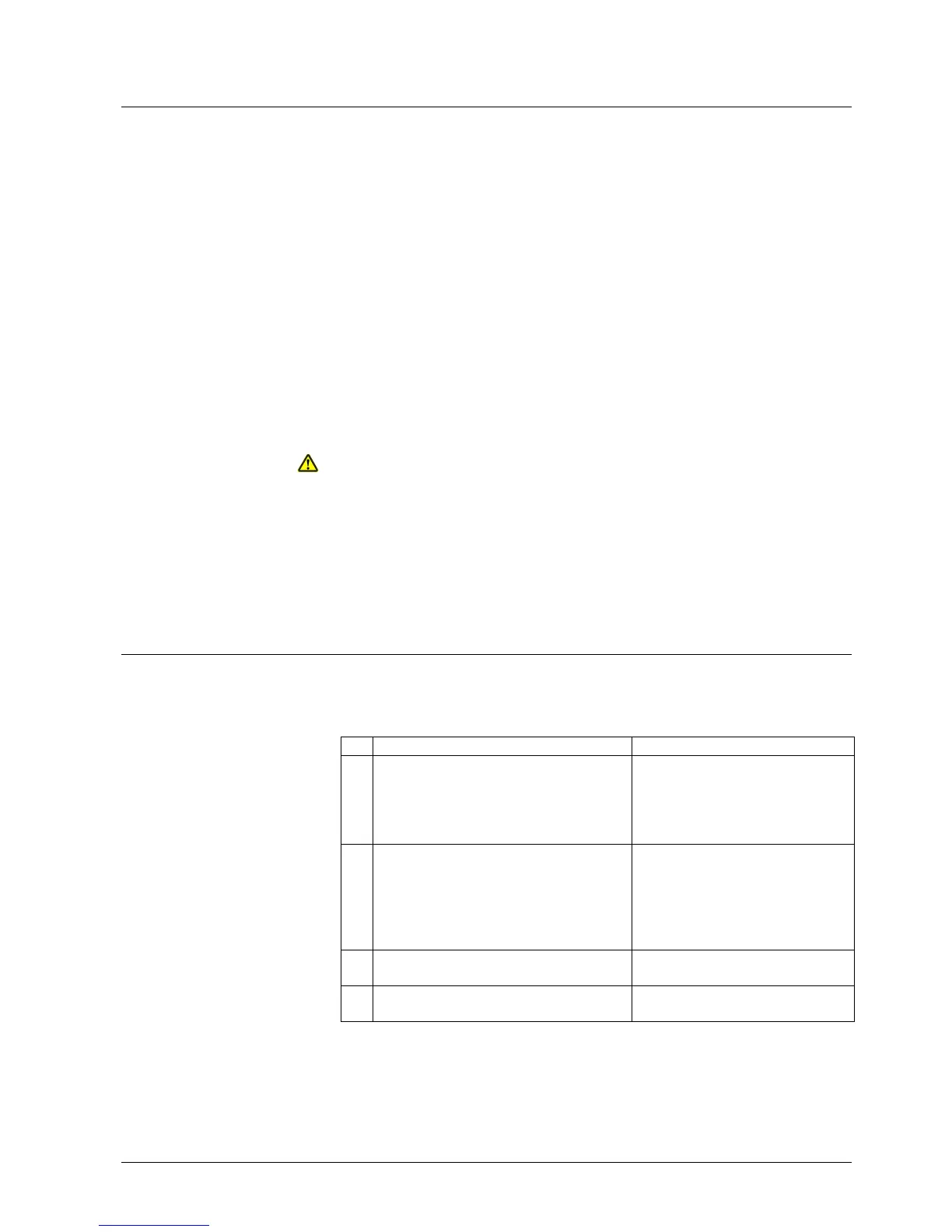

Safety check Anticipated response

a) Burner startup with no flame signal; for

that purpose, open the connection be-

tween burner control and ionization

probe prior to burner startup and main-

tain that status

Lockout at the end of «TSA»

b) Burner operation with simulated loss of

flame during operation; for that purpose,

open the connection between burner

control and ionization probe during

burner operation and maintain that

status

Restart, followed by lockout at the

end of «TSA»

c) No air pressure signal during «t1» (only

with LGA52... / LGA63... with fan)

No startup

d) Air pressure failure during operation

(only with LGA52... / LGA63... with fan)

Shutdown

Loading...

Loading...