Figure 2

Figure 3

Figure 4

Figure 5

The damper stop is provided so that when properly

installed, the chimney damper maintains the minimum

permanent vent opening at all times.

Install damper stop by positioning it over the edge of the

damper blade and tightening the attachment bolt (Fig. 2).

A manual shut-off valve must be included within (6')

six feet of the appliance's gas supply system. This shut-

off valve is not supplied with the appliance. It may be

preferable and more convenient to install the type of shut-

off valve that can be accessed through a wall with a key

(check local building codes).

1. Remove all ashes or other debris from fireplace. If your

fireplace is equipped with an ash dump, the door must

be sealed with high temperature silicone or furnace

cement.

2. Run a ½" NPT black iron gas line through fireplace and

into hearth area, allowing only enough stem to install

the elbow fitting. Prepare incoming black iron gas line

with Teflon tape or pipe joint compound (check with

local codes as to the use of Teflon tape).

A provision must be made for a 1/4" NPT plugged

tapping for a test gauge connection immediately

upstream of the gas supply connection to the

appliance.

3. Position burner base in the center of the fireplace

hearth. Apply pipe thread sealant on the opposite end

of the burner pan gas supply inlet side and install the

d" pipe plug. Tighten securely. Apply thread sealant on

the incoming gas line and install the d" orifice fitting

tightly. Attach the Black SS gas connector to the orifice

fitting (check local codes), be careful not to kink tubing

when hand forming to fit between burner pan and

incoming gas line (Figure 3). Install a gas fitting to the

incoming gas pipe (not provided in kit as piping

systems vary). Connect the gas connector and tighten

nuts.

Multiple tight bends of the gas connector may cause

a whistling noise through the burner. Adjust

connector as required!

4. After gas line connection is complete, turn on gas

supply and check connections for leaks. This is done

by brushing or spraying each fitting from incoming gas

line to log set with a solution of 50% soap and 50%

water. If bubbles appear, further tightening will be

required.

CAUTION! NEVER CHECK FOR LEAKING GAS

CONNECTIONS WITH AN OPEN FLAME.

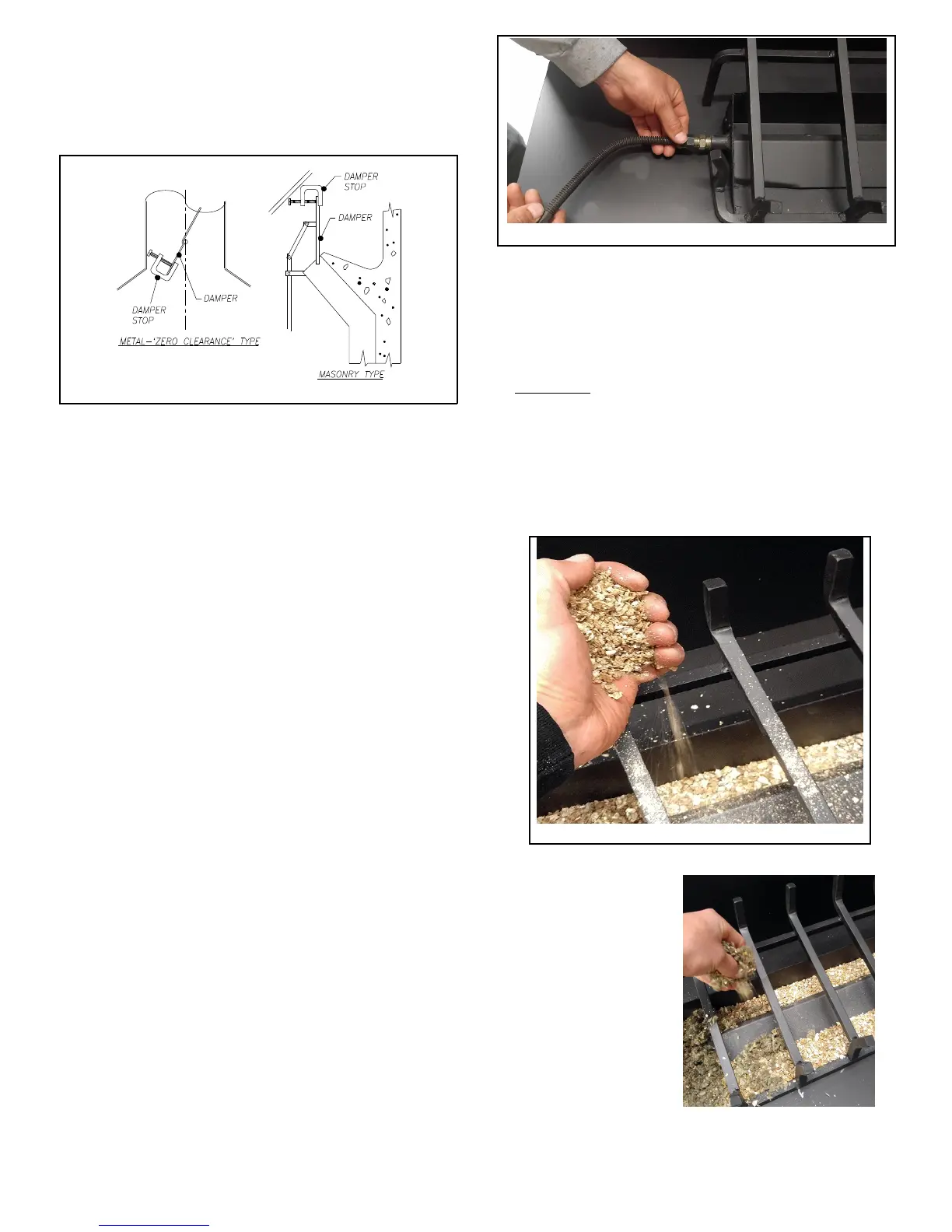

5. Cover the front and rear sections of the burner pan with

the burner granules provided (Fig. 4). Allow the

granules to spill out the front of the burner. The

granules disperses the gas flow and works with the

burner design to create an optimum gas burning

pattern.

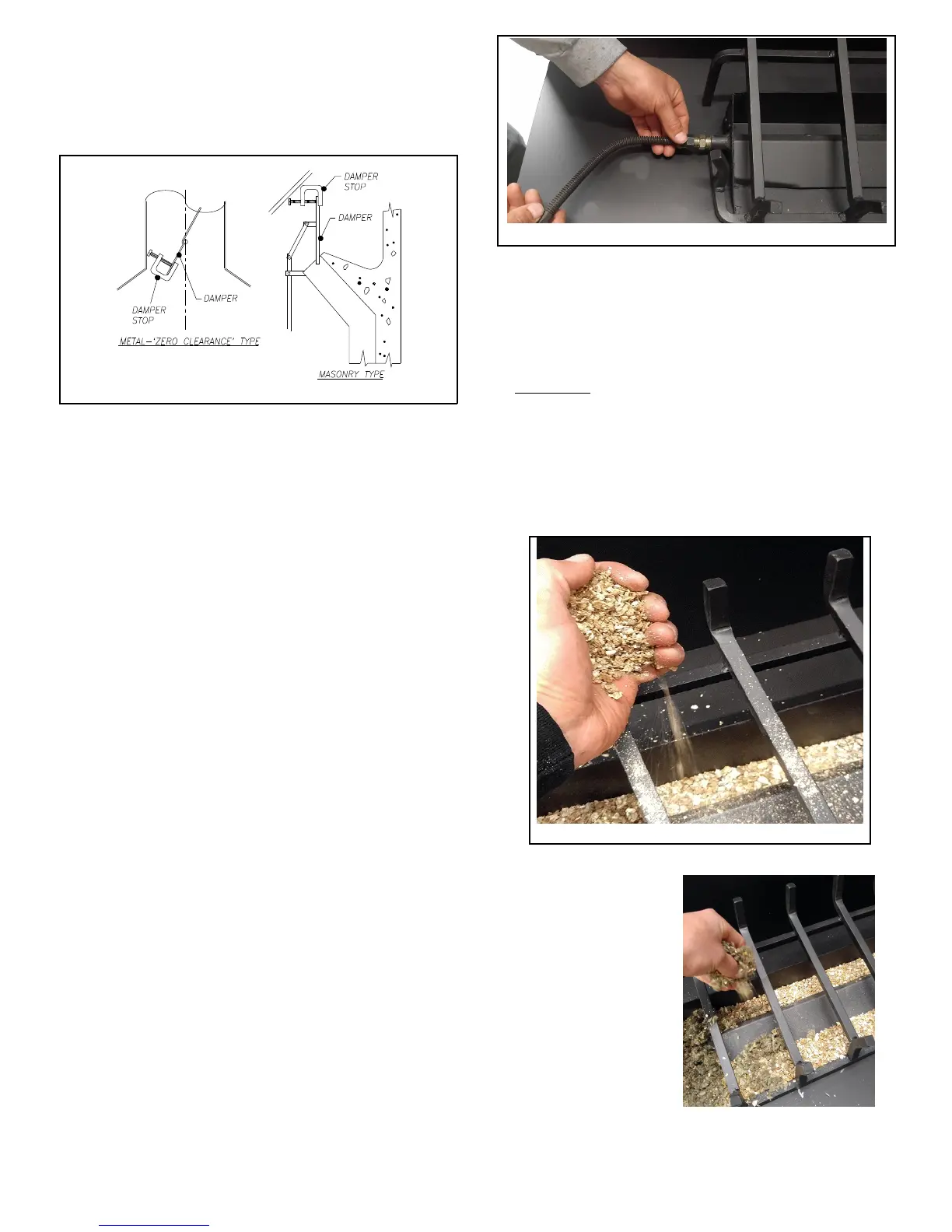

6. Place small pieces

of the ember

material on top of

the burner. (Fig. 5).

The ember materials

glow when the gas

burns providing a

realistic wood fire

effect.

Ver 04/26/16 3 P/N 140032R3

Loading...

Loading...