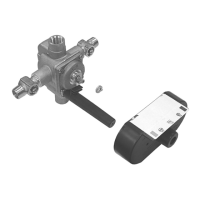

Fig 5

Fig 6

Fig 7

Fig 8

Fig 9

QThe valve body is equipped with service stop valves. Close the hot

and cold water supplies.

QPay close attention to location setting of the mechanical stops (5

and 6). The thick mechanical stop (5) regulates cold temperature,

while the thin top mechanical stop (6) regulates the hot tempera-

ture.

QRemove the mechanical stops, which are below the cap nut in the

center of the valve.

QLoosen the four corner screws (6) and remove the valve cover (7)

with the O-ring (7). The cartridge assembly is now exposed.

QPull the cartridge out. Do not damage the O-ring seals.

QReverse the cartridge 180

o

by turning it upside down. Place it

into the valve body. Two alignment pins located on the rear of

the cartridge must sit in the locating holes within the valve body.

Notice position of hot ("H") and cold ("C") markings on the cartridge

to assure the correct reversal in relation to the back-to-back installa-

tion.

QPut the O-ring on the valve cover. Make sure the surface of the

valve cover, on which the O-ring will sit, and the O-ring are both

clean.

QPosition the valve cover with stop pin facing down. Seat the

cover to the body. Do not pinch the O-ring. The assembly should t

together with a minimum of pressing force.

QTighten up the cover screws, rst lightly and diagonally, and then

more rmly.

QClose the valve by turning the cartridge stem clockwise. Position

the mechanical stops as shown in gure 6 over the cartridge stem

and push it into place. Thread on the cap nut and the stem exten-

sion with All Thread; then you are ready for the trim.

Mechanical

Stops

Stop Pin

2

Stops

Mechanical

Stops

Valve Cover

O-Ring

Cartridge

Assembly

Mud Guard

Tempress II Pressure Balance Valve

Cartridge Replacement Instructions

SigmaFaucetParts.com

Fig 5

Fig 6

Fig 7

Fig 8

Fig 9

QThe valve body is equipped with service stop valves. Close the hot

and cold water supplies.

QPay close attention to location setting of the mechanical stops (5

and 6). The thick mechanical stop (5) regulates cold temperature,

while the thin top mechanical stop (6) regulates the hot tempera-

ture.

QRemove the mechanical stops, which are below the cap nut in the

center of the valve.

QLoosen the four corner screws (6) and remove the valve cover (7)

with the O-ring (7). The cartridge assembly is now exposed.

QPull the cartridge out. Do not damage the O-ring seals.

QReverse the cartridge 180

o

by turning it upside down. Place it

into the valve body. Two alignment pins located on the rear of

the cartridge must sit in the locating holes within the valve body.

Notice position of hot ("H") and cold ("C") markings on the cartridge

to assure the correct reversal in relation to the back-to-back installa-

tion.

QPut the O-ring on the valve cover. Make sure the surface of the

valve cover, on which the O-ring will sit, and the O-ring are both

clean.

QPosition the valve cover with stop pin facing down. Seat the

cover to the body. Do not pinch the O-ring. The assembly should t

together with a minimum of pressing force.

QTighten up the cover screws, rst lightly and diagonally, and then

more rmly.

QClose the valve by turning the cartridge stem clockwise. Position

the mechanical stops as shown in gure 6 over the cartridge stem

and push it into place. Thread on the cap nut and the stem exten-

sion with All Thread; then you are ready for the trim.

Mechanical

Stops

Stop Pin

2

Stops

Mechanical

Stops

Valve Cover

O-Ring

Cartridge

Assembly

Mud Guard

Phone!800-280-4053

Loading...

Loading...