111

IT

ES

PT

GB

4.1 D.H.W. PRODUCTION

“BFT boiler - BT100 tank”

The preparation of hot water is guaranteed

by the glass storage tank unit with magne-

sium anode for the protection of the boiler

unit and inspection flange for its control and

cleaning. The magnesium anode must be

checked annually and substituted when it

is worn. It is advisable to place a sluice gate

at the entrance of the D.H.W. tank unit

which, apart from the total closure, allows

the regulation of the supply capacity.

If the boiler does not produce hot water,

make sure that the air has been released

by pressing on the manual vents after hav-

ing switched off the main switch.

4.2 ADJUSTMENT OF

D.H.W. FLOW RATE

To adjust the hot water flow rate, use the

flow-rate regulator on the pressure switch

valve (7 fig. 5). Remember that the flow

rates and corresponding temperatures of

use of hot water, given in section 1.3, have

been obtained by positioning the selector of

the circulation pump on the maximum value.

Should there be any reduction in the D.H.W.

flow rate, the filter installed on the inlet to

the pressure switch valve (3 fig. 5) will need

cleaning.

To access the filter, you must first

turn off the cold domestic water tap assem-

bled on the template.

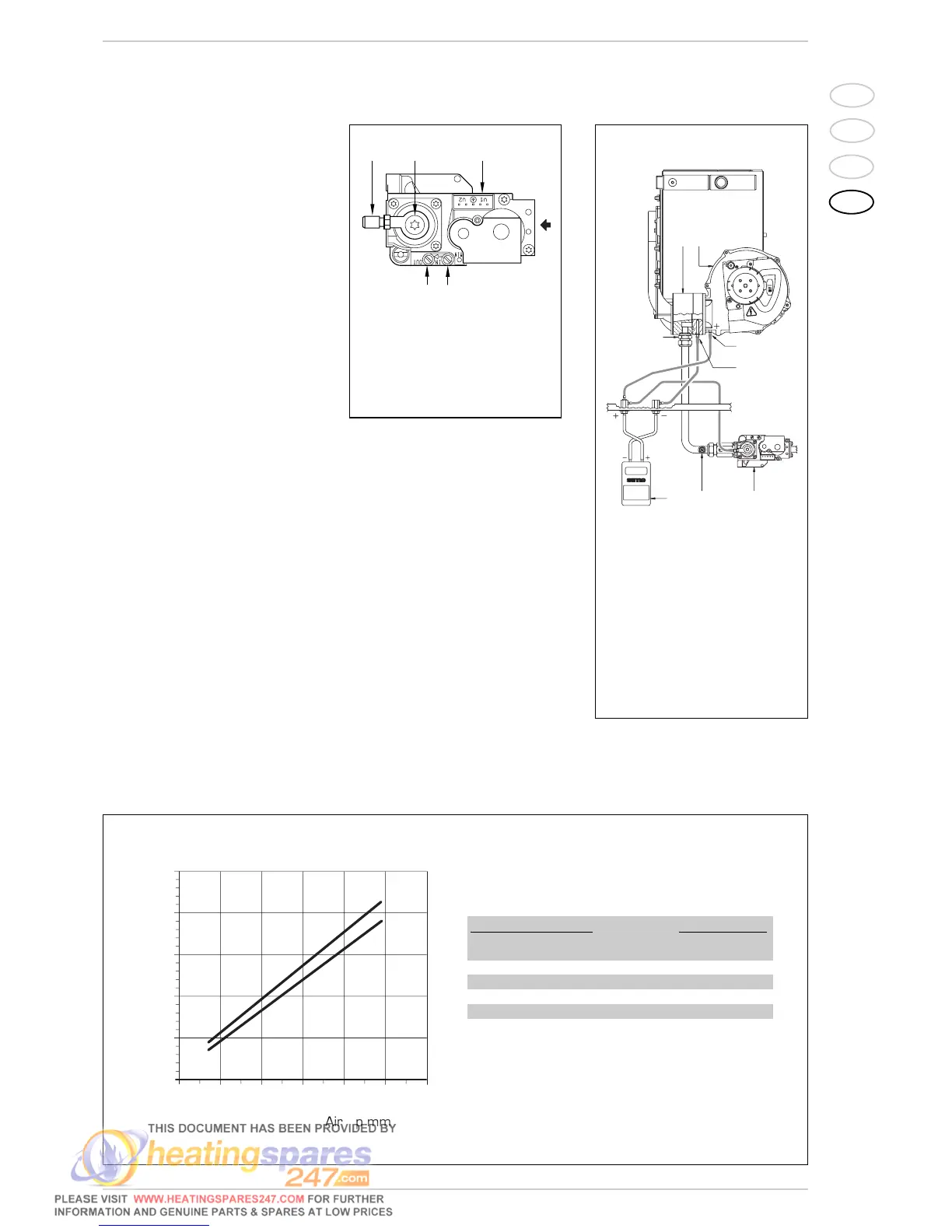

4.3 GAS VALVE

The boiler, is equipped standard with the

HONEYWELL VK 8115M gas valve (fig. 23).

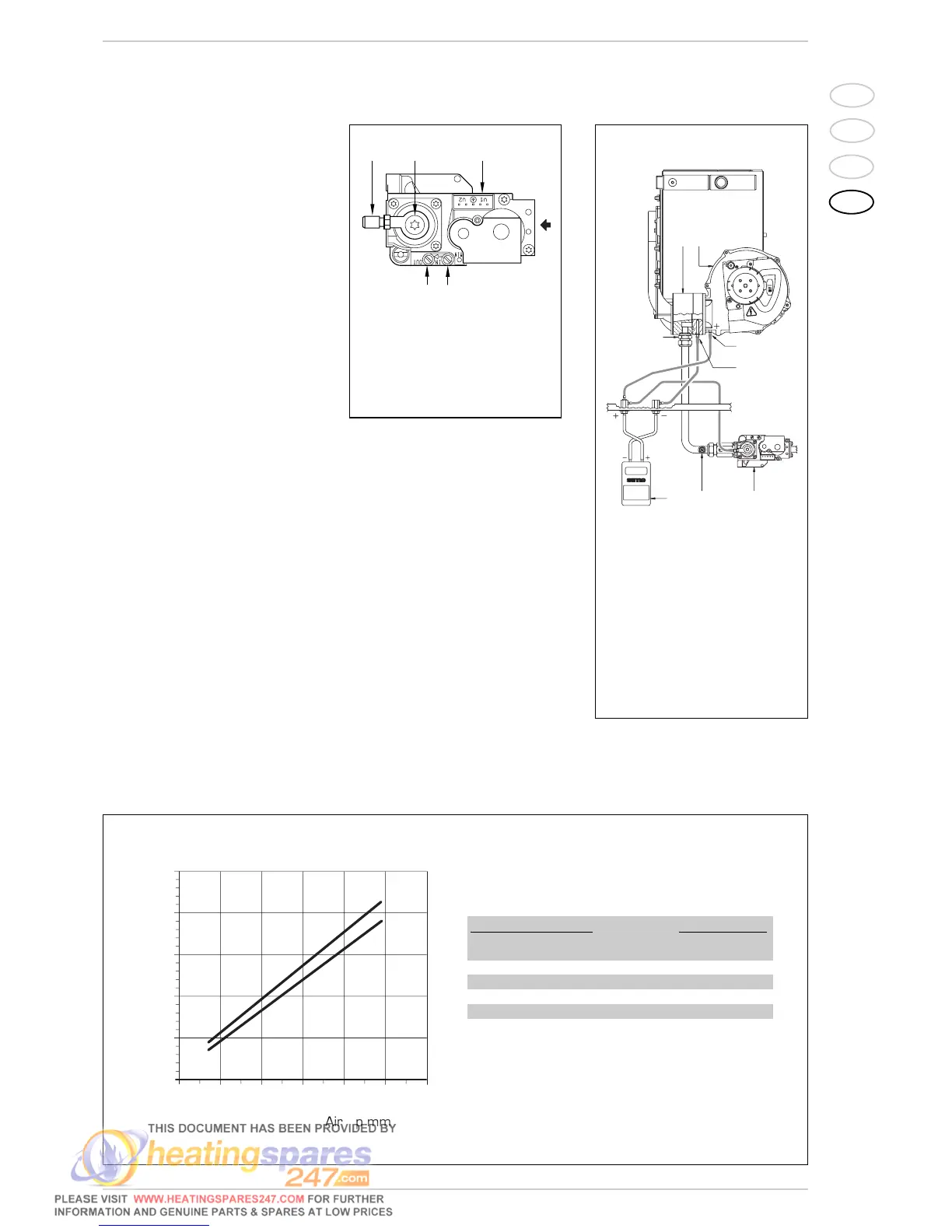

4.4 ADJUSTMENT OF HEAT

OUTPUT FOR HEATING

To adjust boiler heat output for heating pur-

poses, i.e., modifying the setting made at the

factory which is approximately 17 kW, use a

screwdriver to adjust the heating heat out-

put trimmer (10 fig. 20).

To increase working pressure, turn the trim-

mer clockwise; to reduce pressure, turn the

trimmer counterclockwise.

To determine boiler heat output setting,

check energy consumption by observing the

meter and then compare with the values

shown in Tables 4 - 4/a - 4/b; or measure

“air ∆p” with a digital pressure gauge con-

nected up as shown in fig. 24.

Compare values with those shown in Tables

4 - 4/a - 4/b.

4 USE AND MAINTENANCE

Loading...

Loading...