–

“25 BF - 30 BF” models: using the fill cock

on the pressure switch valve (2 fig. 5).

– “25 BFT - 30 BFT” model: using the fill

cock (29 fig. 2).

The charge pressure, with the system cold,

must be 1 bar.

Filling must be done slowly so as to allow

any air bubbles to be bled off through the air

valves.

When you have finished filling the system

close the fill cock.

2.6 COAXIAL DUCT

ø 60/100

The air inlet-smoke outlet assembly, code

8096250, is included in the standard sup-

ply of the appliance complete with mounting

instructions.

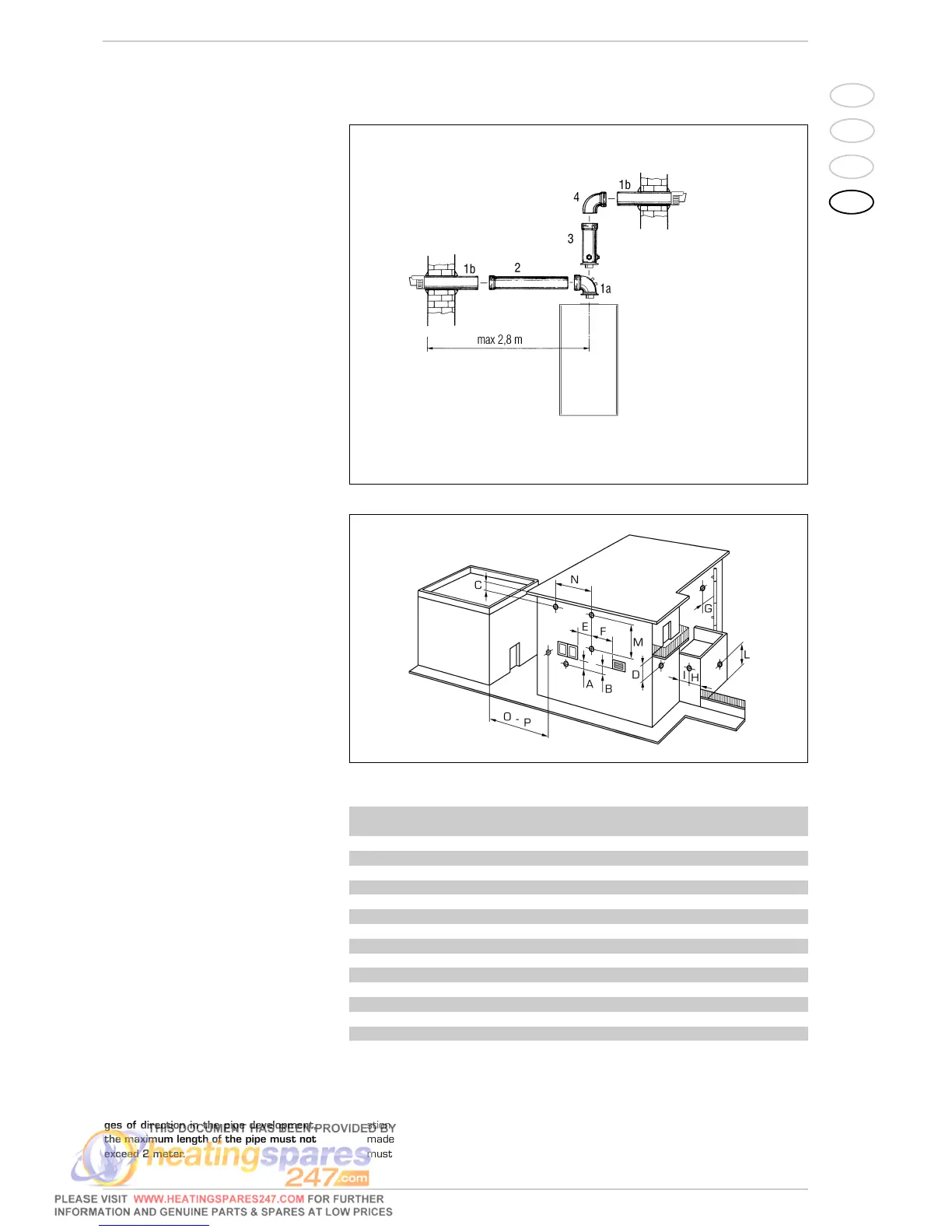

2.6.1 Coaxial duct

accessories

The accessories to be used for this type of

installation and some of the connecting

systems that may be adopted are illustred

in fig. 6.

With the pipe bend included in the kit, the

maximum length of the piping should not

exceed 2.8 meter.

When the vertical extension code

8086950 is used, the terminal part of the

pipe must always come out horizontally.

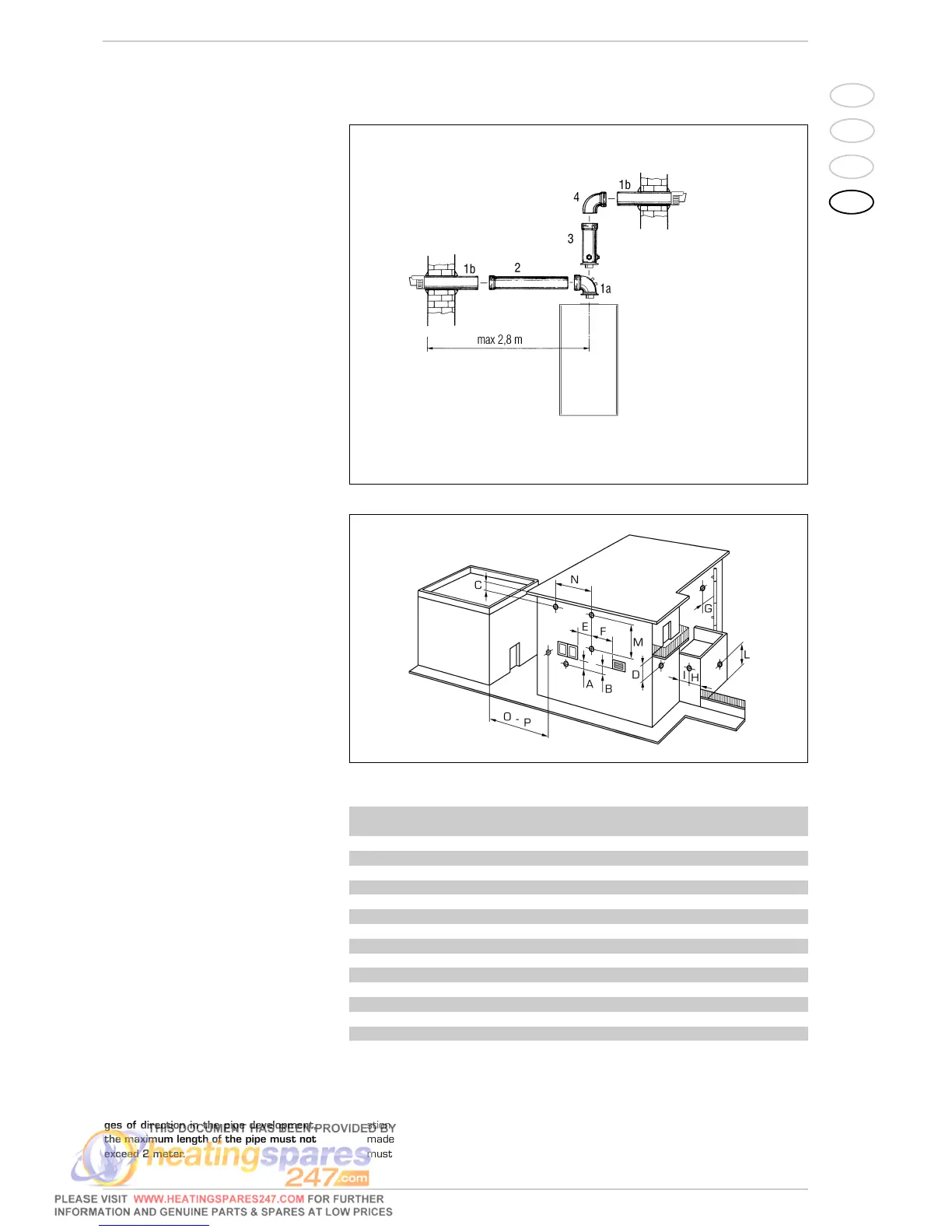

2.6.2 Positioning the

outlet terminals

The outlet terminals for forced-draught

appliances may be located in the external

perimeter walls of the building.

To provide some indications of possible solu-

tions, Table 1 gives the minimum distances

to be observed, with reference to the type

of building shown in fig. 7.

2.6.3 Coaxial duct outlet

on the roof

The roof discharge terminal L. 1285 cannot

be shortened and when positioning the tile,

the minimum distance from the discharge

head terminal must not be less than 600

mm (fig. 8).

The accessories to be used for this type of

installation and some of the connecting

systems that may be adopted are illustra-

ted in fig. 9.

It is possible to insert up to a maximum of

three extensions and reach a maximum

rectilinear distance of 3.7 meter.

Should it be necessary to make two chan-

ges of direction in the pipe development,

the maximum length of the pipe must not

exceed 2 meter.

99

IT

ES

PT

GB

Fig. 6

KEY

1a-b Coaxial duct kit code 8096250

2a Extension L. 1000 code 8096150

2b Extension L. 500 code 8096151

3 Vertical extension L. 140

with take-off point code 8086950

4a 90° additional bend code 8095850

4b 45° additional bend code 8095950

TABLE 1

Siting of terminal Appliances from 7 to 35 kW

(distances in mm)

A - below openable window 600

B - below ventilation opening 600

C - below eaves 300

D - below balcony (1) 300

E - from adjacent window 400

F - from adjacent ventilation opening 600

G - from horizontal or vertical soil or drain pipes (2) 300

H - from corner of building 300

I - from recess in building 300

L - from ground level or other treadable surface 2500

M - between two terminals set vertically 1500

N - between two terminals set horizontally 1000

O - from a surface facing without openings or terminals 2000

P - as above but with openings and terminals 3000

1)

Terminals below a practicable balcony must be located in such a way that the total path of

the smoke from its outlet point from the terminal to its outlet point from the external peri-

meter of the balcony, including the height of possible railings, is not less than 2000 mm.

2) When siting terminals, where materials that may be subject to the action of the combu-

stion products are present in the vicinity, e.g., eaves, gutters and downspouts painted or

made of plastic material, projecting timberwork, etc., distances of not less than 1500 mm

must be adopted, unless adequate shielding is provided to guard these materials.

Fig. 7

IMPORTANT:

Each additional 90° curve installed reduces the available length by 0.90 metres.

Each additional 45° curve installed reduces the available length by 0.45 metres.

NOTE

Before connecting accessories,

it is always advisable to lubricate

the internal part of the gaskets

with silicon products. Avoid using

oils and greases.

Loading...

Loading...