11

a)

The available pump head is given in fig. 20.

b) The burner starts when the C.H. flow

reaches 400÷450 l/h. This safety con-

dition is ensured by the flow switch.

c) The appliance is equipped with an inter-

nal by-pass that operates with system

heads (H) greater than 3 m. The maxi-

mum flow through the by-pass is about

300 l/h. If thermostatic radiator valves

are to be installed, at least one radiator

should be without a thermostatic valve

(usually the bathroom radiator).

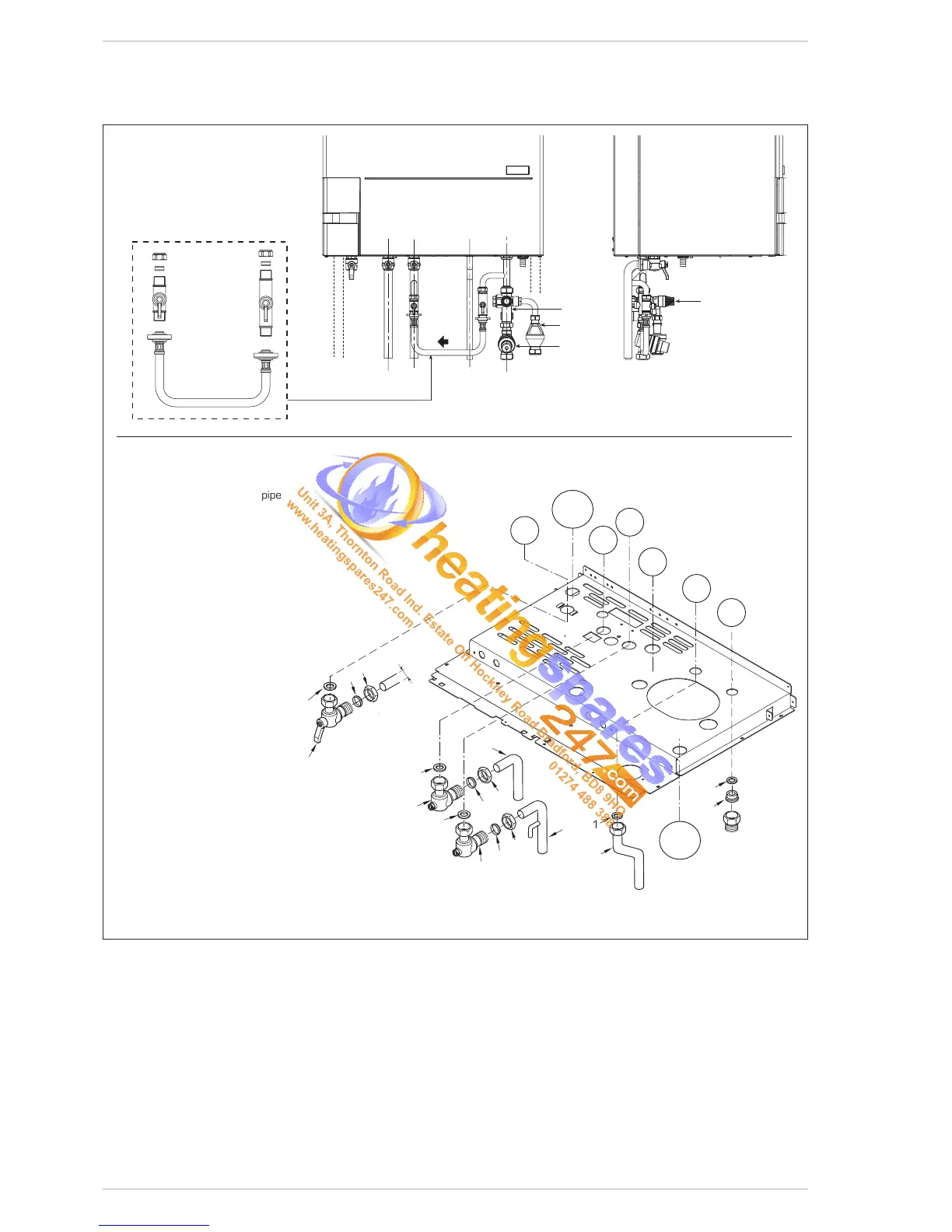

d) A sealed system must only be filled by a

competent person using the filling loop

as shown in fig 5.

e) To fill the cylinder, open a DHW tap,

then turn on the domestic water supply.

When water runs from the tap turn it

off. Repeat at each DHW tap.

NOTE: there should be no isolation valve

fitted between the cylinder and the

expansion valve.

f) To drain the cylinder see fig. 2 number

23.

2.4.3 Discharge Pipes and fittings

The position of any tundish must be visible

to the occupants and any tundish, drain

valve and discharge pipe and must be sited

away from any electrical components.

The 7 and 3 bar PRV's are called out with

the number 15 and 22 on fig. 3.

The connections to the expansion relief

valve and temperature and pressure relief

valve should not be used for any other pur-

pose.

See fig. 6 for example of the discharge

pipe(s) for the temperature and pressure

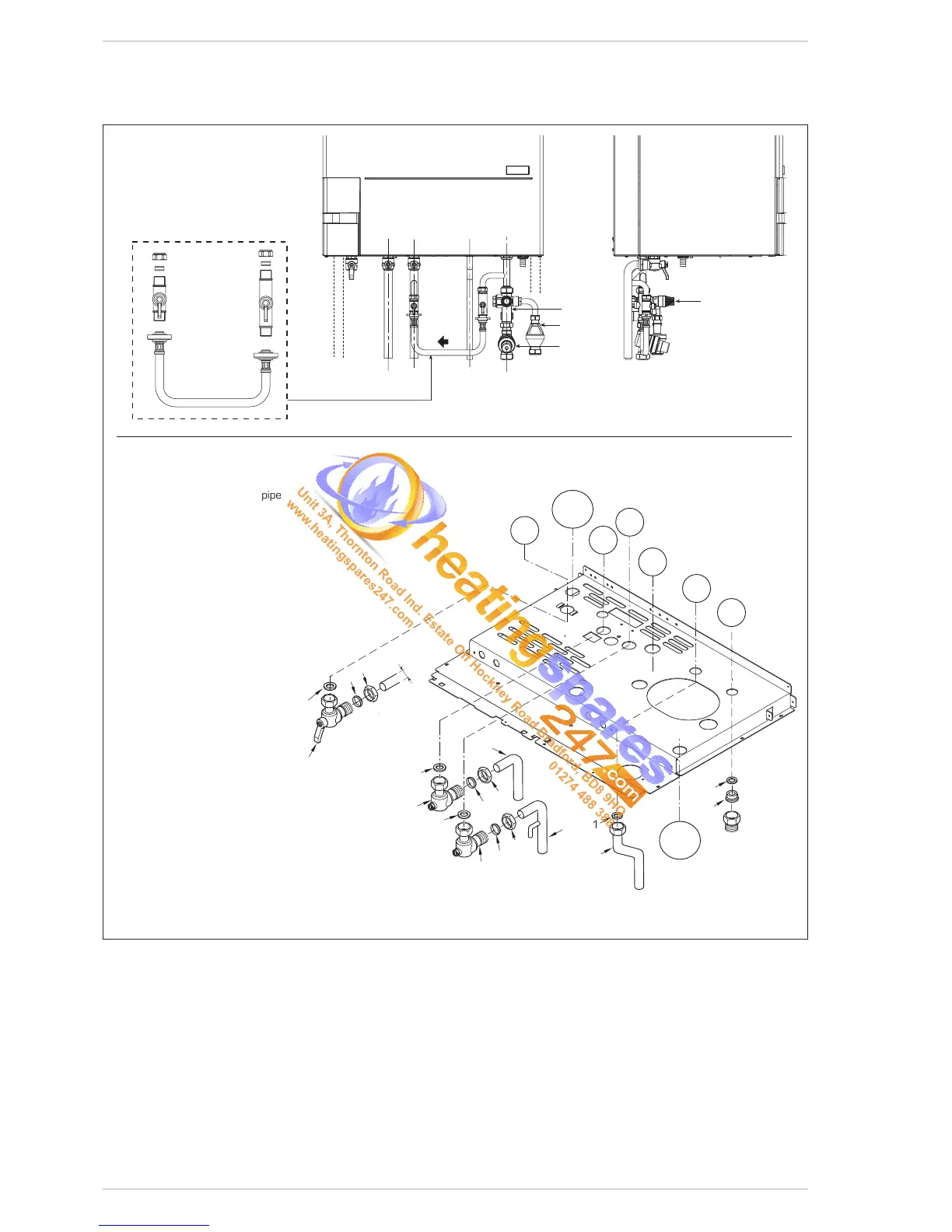

Fig. 5

KEY

1 Gasket ø 11,5/18,5 x 2

6 Gasket ø 17/24 x 2

8 Brass olive for 22 mm pipe

9 Locking nut 1-1/8”

10 Cock 3/4”

11 Flow regulator

12

Gas cock

13 Filling loop

14 Expansion relief valve

15 Tundish expansion relief valve

16 Single check valve

17 Pressure reducing valve

18 Curve return system

19 Curve flow system

20 D.H.W. outlet pipe

21 Brass olive for 15 mm pipe

22 Locking nut 1/2”

CONNECTIONS

G Gas inlet

M C.H. flow

R C.H. return

U D.H.W. outlet

E D.H.W. inlet

S3 Condensation outlet

DS 3 3 bar discharge

DS 7 7 bar discharge

DS 3

DS 7

No isolation valve should be fitted

between the cylinder and the

expansion valve.

Loading...

Loading...