SINAMICS G120

Standard inverters 0.37 kW to 250 kW (0.5 hp to 400 hp)

SINAMICS G120 standard inverters

4/10

Siemens D 11.1 · 2009

4

■

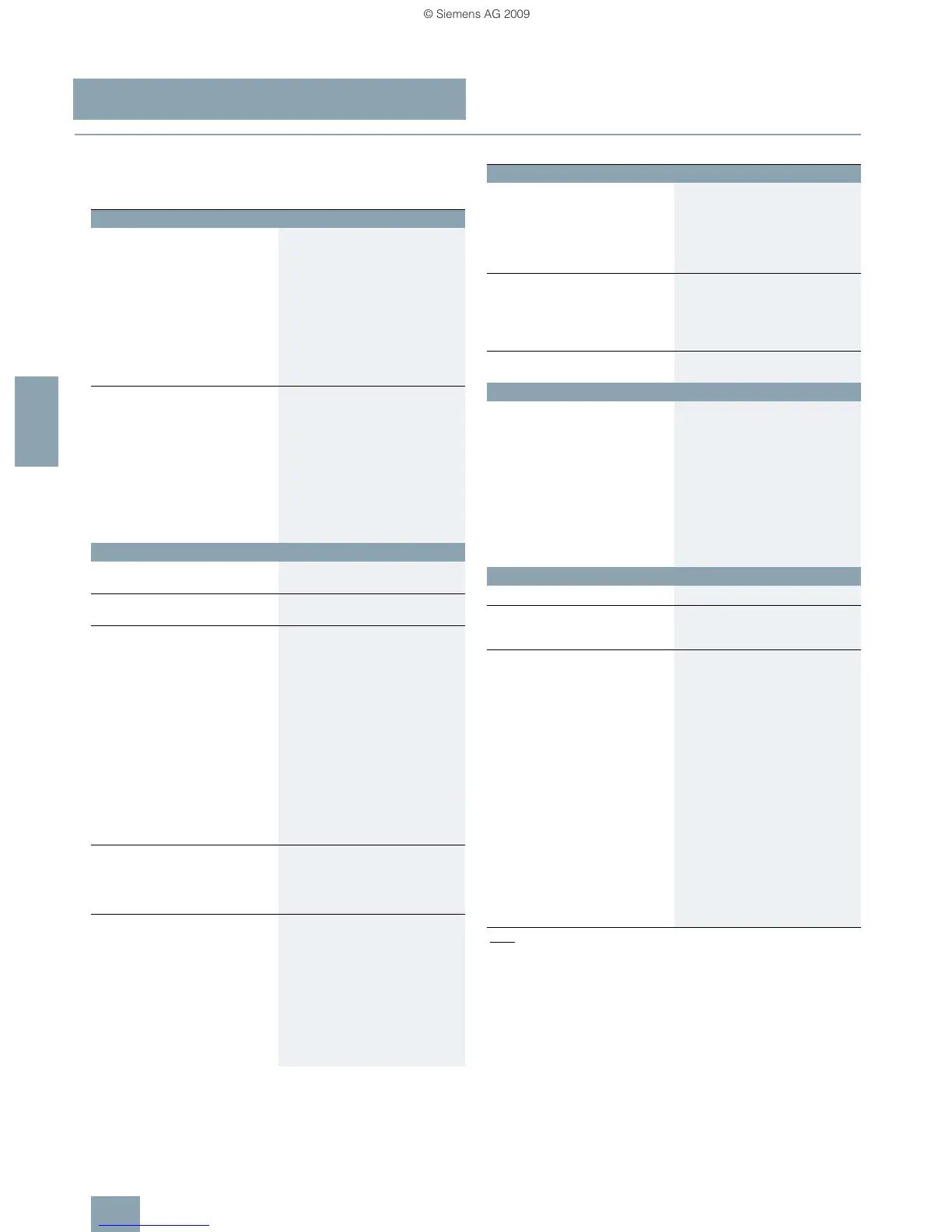

Technical specifications

Unless explicitly specified otherwise, the following technical

specifications are valid for all the following components of the

SINAMICS G120 standard inverters.

Mechanical specifications

Vibratory load

•Transport

1)

acc. to EN 60721-3-2

- All units and components

except frame size FSGX

- Units with frame size FSGX

Class 2M3

Class 2M2

• Operation

Test values acc. to EN 60068-2-6 Test Fc:

10 … 58 Hz: Constant deflection

0.075 mm

58 … 150 Hz: Constant accelera-

tion = 9.81 m/s

2

(1 × g)

Shock load

•Transport

1)

acc. to EN 60721-3-2

- All units and components

except frame size FSGX

- Units with frame size FSGX

Class 2M3

Class 2M2

• Operation

Test values acc. to

EN 60068-2-27

- Frame sizes FSA to FSC

- Frame sizes FSD to FSF

- Frame size FSGX

Test Ea:

147 m/s

2

(15 × g)/11 ms

49 m/s

2

(5 × g)/30 ms

98 m/s

2

(10 × g)/20 ms

Ambient conditions

Protection class

acc. to EN 61800-5-1

Class I (with protective conductor

system) and Class III (PELV)

Touch protection

acc. to EN 61800-5-1

For the intended purpose

Permissible ambient and coolant

temperature (air) during opera-

tion for line-side power compo-

nents and Power Modules

• High overload

(HO)

0…50°C (32…122°F) without

derating

(for PM240, frame size FSGX:

0 … 40 °C),

> 50 … 60 °C see derating

characteristics

• Light overload

(LO)

0…40°C (32…104°F) without

derating

(for PM240, frame size FSGX:

0 … 40 °C),

> 40 … 60 °C see derating

characteristics

Permissible ambient and coolant

temperature (air) during opera-

tion for Control Units, additional

system components and DC-link

components

–10…+50°C (14…122°F)

with CU240S DP-F: 0 … 45 °C

with CU240S PN-F: 0 … 40 °C

with IOP: 0 … 50 °C

up to 2000 m above sea level

Climatic ambient conditions

•Storage

1)

acc. to EN 60721-3-1 Class 1K3

temperature –25 … +55 °C

•Transport

1)

acc. to EN 60721-3-2 Class 2K4

temperature –40 … +70 °C

max. humidity 95 % at 40 °C

• Operation acc. to EN 60721-3-3 Class 3K5

4)

Condensation, splashwater and

ice formation not permitted

(EN 60204, Part 1)

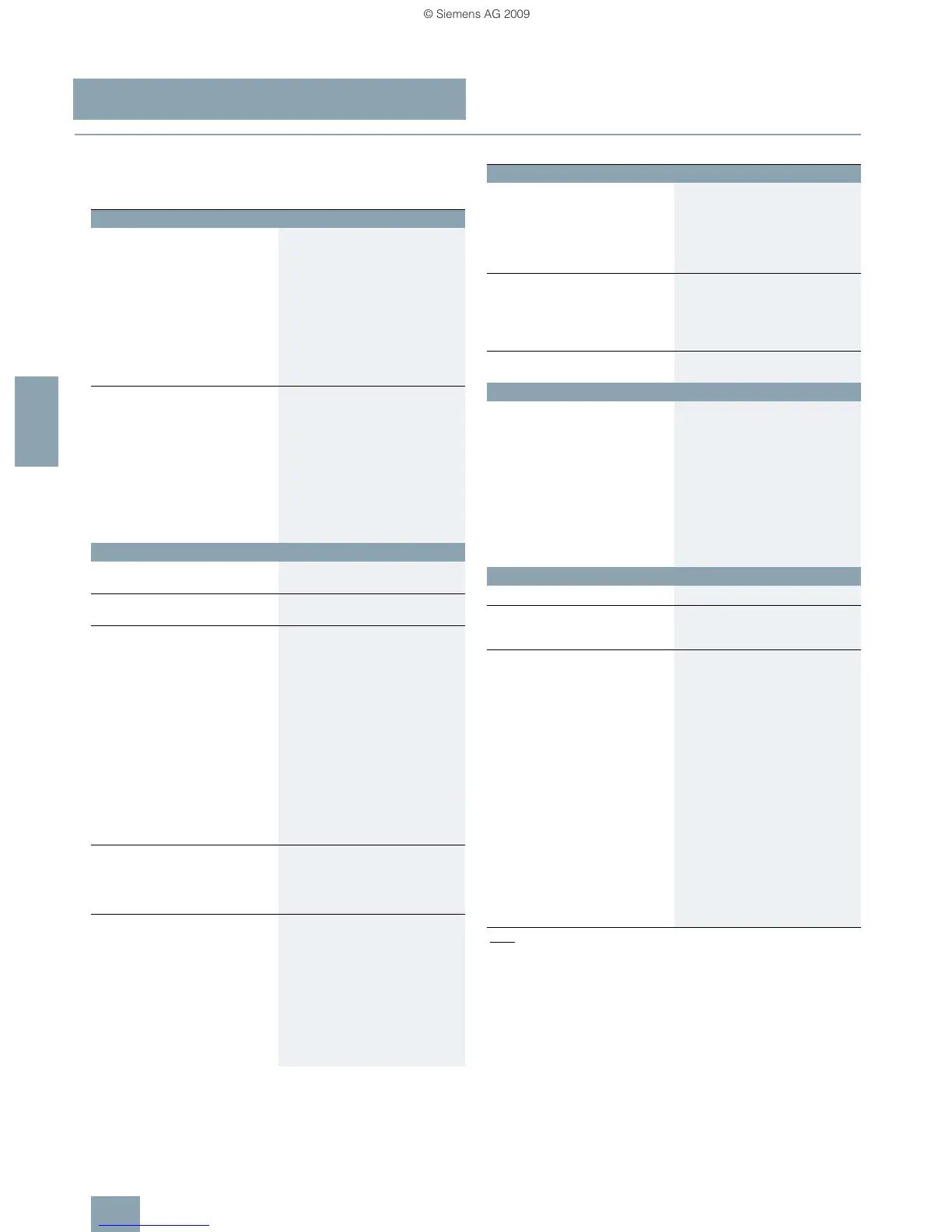

Ambient conditions (continued)

Environmental class/harmful

chemical substances

•Storage

1)

acc. to EN 60721-3-1 Class 1C2

•Transport

1)

acc. to EN 60721-3-2 Class 2C2

• Operation acc. to EN 60721-3-3 Class 3C2

Organic/biological influences

•Storage

1)

acc. to EN 60721-3-1 Class 1B1

•Transport

1)

acc. to EN 60721-3-2 Class 2B1

• Operation acc. to EN 60721-3-3 Class 3B1

Degree of pollution

acc. to EN 61800-5-1

2

Certification for fail-safe versions

Applies to CU240 DP-F and

CU240 PN-F Control Units.

The values include Control Unit,

Power Module and Safe Brake

Relay.

• Category acc. to EN 954-1 3

• SIL Cl acc. to IEC 61508 2

• PL acc. to ISO 13849 Available soon

•PFH

D

5 × 10

–8

•T1 10 Years

Standards

Standards conformance UL, cUL, CE, c-tick

CE mark According to Low-Voltage Direc-

tive 73/23/EEC and Machinery

Directive 98/37/EC

EMC Directive acc. to EN 61800-3

• Frame sizes FSA to FSGX without

integrated line filter class A

Category C3

2)

• Frame sizes FSB to FSF with

integrated line filter class A

Category C2

3)

(corresponds to class A acc. to

EN 55011 for conducted interfer-

ence emission)

• Frame size FSA without integra-

ted line filter and with additional

line filter class A

Category C2

3)

(corresponds to class A acc. to

EN 55011 for conducted interfer-

ence emission)

• Frame size FSA with additional

line filter class A and with addi-

tional line filter class B

Category C2

3)

(corresponds to class B acc. to

EN 55011 for conducted interfer-

ence emission)

• Frame sizes FSB and FSC with

additional line filter class A and

with additional line filter class B

Category C2

3)

(corresponds to class B acc. to

EN 55011 for conducted interfer-

ence emission)

Note: The EMC product standard EN 61800-3 does not apply directly

to a frequency inverter but to a PDS (Power Drive System), which com-

prises the complete circuitry, motor and cables in addition to the fre-

quency inverters. The frequency inverters on their own do not generally

require identification according to the EMC Directive.

1)

In transport packaging.

2)

Unfiltered inverters can be used in industrial environments as long as they

are part of a system that contains line filters on the higher-level infeed side.

As a consequence, a PDS (Power Drive System) can be installed accor-

ding to C3.

3)

With shielded motor cable up to 25 m.

4)

For Intelligent Operator Panel IOP, class 3K3.

Loading...

Loading...