DC INVERTER U-MATCH AIR CONDITION MAINTENANCE

161

Removal and Installation of Oil-Liquid Separator

Remarks: Before removing the oil-liquid separator, make sure that there is no refrigerant

inside the pipe system and that the power has been cut off.

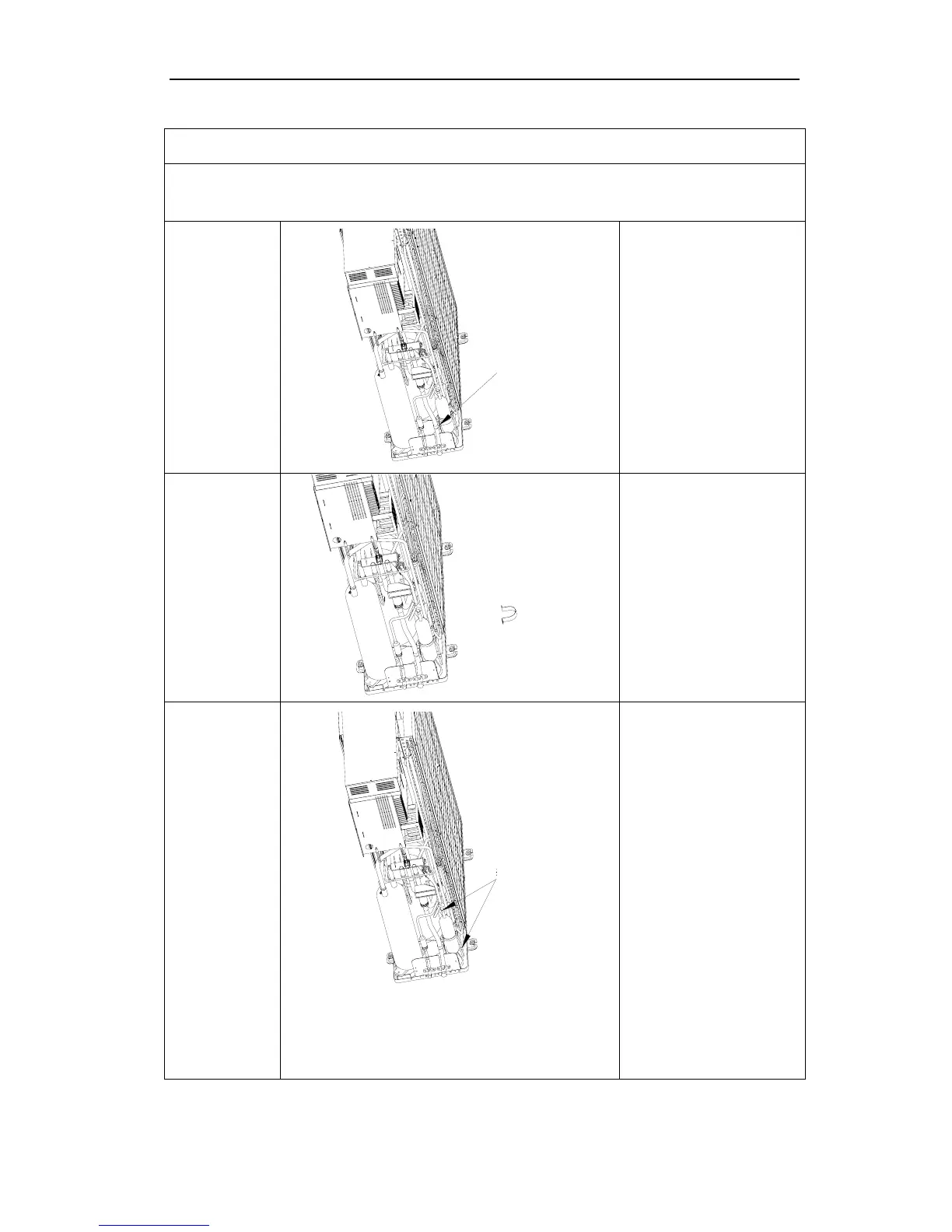

1. Remove the

screws fixing the

oil-liquid

separator

● Firstly, cut off the power.

● Recycle the refrigerant

properly.

● Use screwdriver to loosen

the screws fixing the oil-liquid

separator.

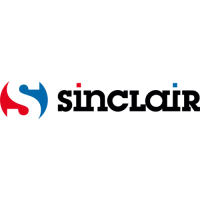

2. Remove the

fixing clamp of

oil-liquid

separator

● Remove the oil-liquid

separator fixing clamp from

the support.

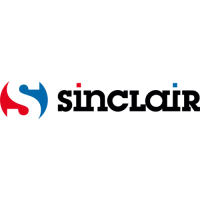

3. Remove the

inlet and outlet

connection pipes

of oil-liquid

separator

●Use gas welding to heat the

inlet and outlet connection

pipes on oil-liquid separator.

Then, pull them out from the

oil-liquid separator.

● Weld by charging nitrogen

for protection, with the

nitrogen pressure kept at

0.5±0.1kgf/c (relative

pressure).

● During heating, take care

to prevent the substances

around from burn due to high

temperature.

Remove the inlet and

outlet connection

pipes of oil-liquid

separator

Remove the screws

fixing the oil-liquid

separator

Loading...

Loading...