cs

F \

H

ta

r

h

41/

D F2

G

A

22

There should be no necessity for removing or

taking this tension apart. However if, for any

reason, it becomes necessary to remove the tension,

proceed as follows:

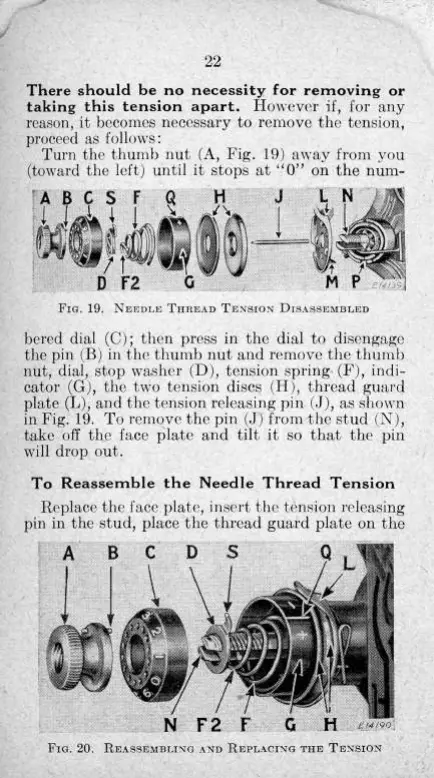

Turn the thumb nut (A, Fig. 19) away from you

(toward the left) until it stops at "0" on the num-

FIG. 19. NEEDLE THREAD TENSION DISASSEMBLED

bered dial (C); then press in the dial to disengage

the pin (B) in the thumb nut and remove the thumb

nut, dial, stop washer (D), tension spring- (F), indi-

cator (G), the two tension discs (H), thread guard

plate (L), and the tension releasing pin (J), as shown

in Fig. 19. To remove the pin (J) from the stud (N),

take off the face plate and tilt it so that the pin

will drop out.

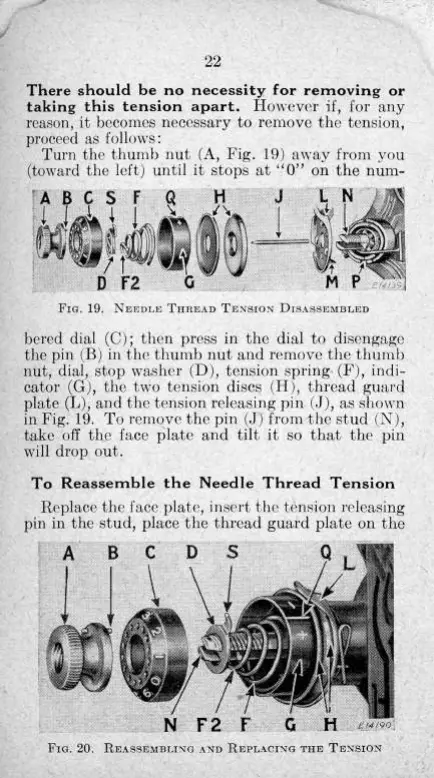

To Reassemble the Needle Thread Tension

Replace the face plate, insert the tension releasing

pin in the stud, place the thread guard plate on the

FIG. 20. REASSEMBLING AND REPLACING THE TENSION

22

There

should be no necessity for removing or

taking

this

tension

apart.

However if, for any

reason, it

becomes

necessary to remove the tension,

proceed

as follows:

Turn

the thumb nut (A, Fig. 19) away from you

(toward the left)

until

it

stops

at "0" on the num-

FiG. 19,

NEEDLE

THREAD

TENSION

DISASSEMBLED

bered

dial

(C); then press in the

dial

to

disengage

the pin (B) in the thumb nut and remove the thumb

nut,

dial,

stop

washer (D), tension spring (F),

indi-

cator (G), the two tension discs (H), thread guard

plate

(L),

and the tension releasing pin

(J),

as shown

in Fig.

19. To remove the pin (J) from the stud (N),

take

off the face plate and

tilt

it so that the pin

will

drop

out.

To

Reassemble the Needle

Thread

Tension

Replace the face plate, insert the tension releasing

pin

in the stud, place the thread guard plate on the

Fic;.

20.

fii:\-si:\iHi,l\<:

wu

i

I

ij'i.\r! NCJ THE

TENSION

N

F2

F

G

n

Loading...

Loading...