23

stud, being sure that the lug (M, Fig. 19) engages

the short recess (P) to prevent the plate from turn-

ing on the stud. Next, place the two tension discs

(H) on the stud, having the flat thread-bearing sides

of the discs together; then replace the indicator (G)

with the large open side facing end of stud so that

the plus and minus signs will be readily seen from a

sewing position as shown in Fig. 20. Insert the ten-

sion spring (F) in the indicator so that the first half

turn of this spring will straddle the lower half of the

tension stud. Guide the stop washer (D) onto the

stud so that the extension (S) will be above the

tension stud as shown_ in Fig. 20.

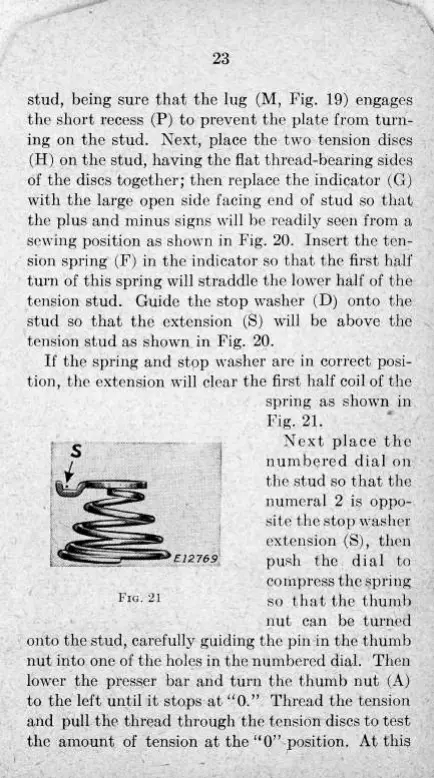

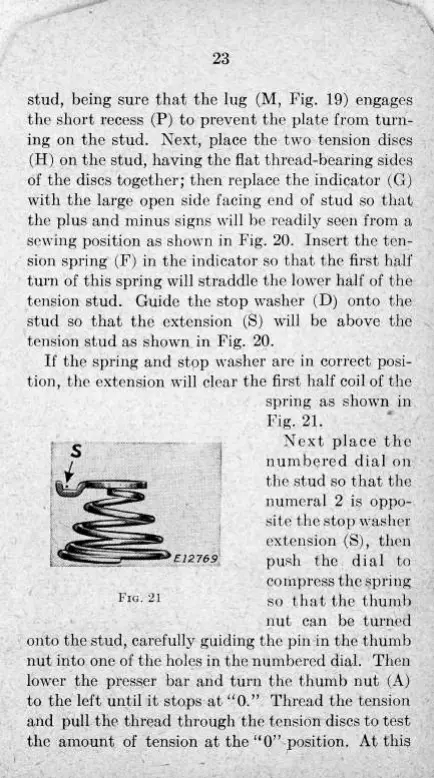

If the spring and stop washer are in correct posi-

tion, the extension will clear the first half coil of the

spring as shown in

Fig. 21.

Next place the

numbered dial on

the stud so that the

numeral 2 is oppo-

site the stop washer

extension (S), then

E 1 2 769

push the dial to

compress the spring

FIG. 21

so that the thumb

nut can be turned

onto the stud, carefully guiding the pin in the thumb

nut into one of the holes in the numbered dial. Then

lower the presser bar and turn the thumb nut (A)

to the left until it stops at "0." Thread the tension

and pull the thread through the tension discs to test

the amount of tension at the "0" position. At this

23

stud,

being sure that the lug (M, Fig. 19)

engages

the short recess (P) to prevent the plate from

turn-

ing

on the stud. Next, place the two tension discs

(H)

on the stud, having the fiat thread-bearing sides

of the discs together; then replace the indicator (G)

with

the large

open

side facing end of stud so that

the plus and minus signs

will

be readily seen from a

sewing position as shown in Fig. 20.

Insert

the ten-

sion spring (F) in the indicator so that the

first

half

turn

of this spring

will

straddle the lower

half

of the

tension stud. Guide the

stop

washer (D)

onto

the

stud

so that the extension (S)

will

be

above

the

tension stud as shown in Fig. 20.

If

the spring and

stop

washer are in correct posi-

tion,

the extension

will

clear the

first

half

coil of the

onto

the stud, carefully guiding the pin in the thumb

nut

into one of the holes in the numbered

dial.

Then

lower the presser bar and

turn

the thumb nut (A)

to the left

until

it

stops

at '^0." Thread the tension

and

pull

the thread through the tension discs to test

the amount of tension at the "0" position. At this

spring

as shown in

Fig.

21.

s

FIG.

21

Next

place the

numbered

dial

on

the stud so that the

numeral

2 is

oppo-

site

the

stop

washer

extension (S), then

push the

dial

to

compress

the spring

so that the thumb

nut

can be turned

Loading...

Loading...