From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

THREAD

On Machines of Class 331 K,

use only left twist

thread

in

the needle. Either right

or

left twist

thread

can

be

used

in

the bobbin.

To

determine the

thread

twist, hold the

thread

as

shown

in

Fig.

6.

Then twirl the

thread

over

toward you.

If

the strands

of

the

thread

wind tighter, the

thread

is

left twist, if the strands unwind

or

separate,

the

thread

is

right twist. Rough

or

uneven

thread,

or

thread

which

passes with difficulty through the

eye

of

the needle,

will

interfere with the successful use

of

the machine.

NEEDLES

The

needle

you select

will

have a very direct effect

on the quality, strength

and

appearance

of

the stitch

produced

by

the machine.

In

selecting a

needle

size

...

the

eye

must

be

large

enough to allow the

thread

you

are

using to

pass

through freely without binding

or

chafing. A simple

test

is

to

thread

a short length

of

thread

through the

eye

of

the

needle

selected; hold the

thread

taut

in

a

vertical position .and twirl the

needle

about

the

thread.

If

the size

is

correct, the

needle

should slip down the

thread

easily.

Needles for this machine

are

of

Catalog

#2055

(16

x 87)

in

Sizes 8 to 14, 16 to 19 and

21

to 25.

Orders for needles

must

specify the Quantity

required, the Size number, also the Catalog number.

For example:

"100

Size 16, Catalog #2055

(16

x 87) Needles"

For best results always use

SINGER

needles.

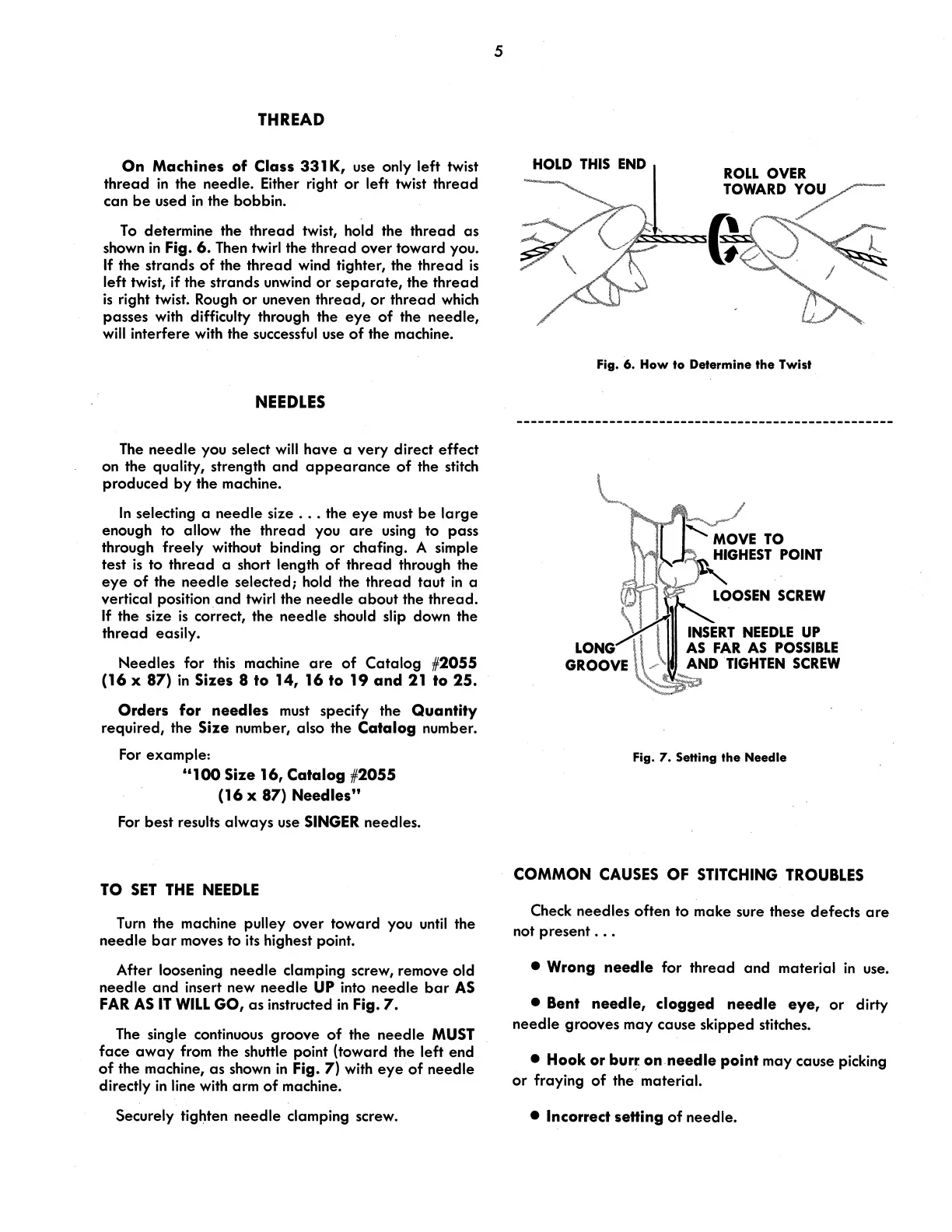

TO

SET

THE

NEEDLE

Turn

the machine pulley

over

toward you

until

the

needle

bar

moves to its highest point.

After loosening

needle

clamping screw, remove old

needle

and

insert new

needle

UP

into

needle

bar

AS

FAR

AS

IT

WILL

GO,

as

instructed

in

Fig.

7.

The single continuous groove

of

the

needle

MUST

face

away

from the shuttle point (toward the left end

of

the machine,

as

shown

in

Fig. 7) with

eye

of

needle

directly

in

line with arm

of

machine.

Securely tighten

needle

clamping screw.

5

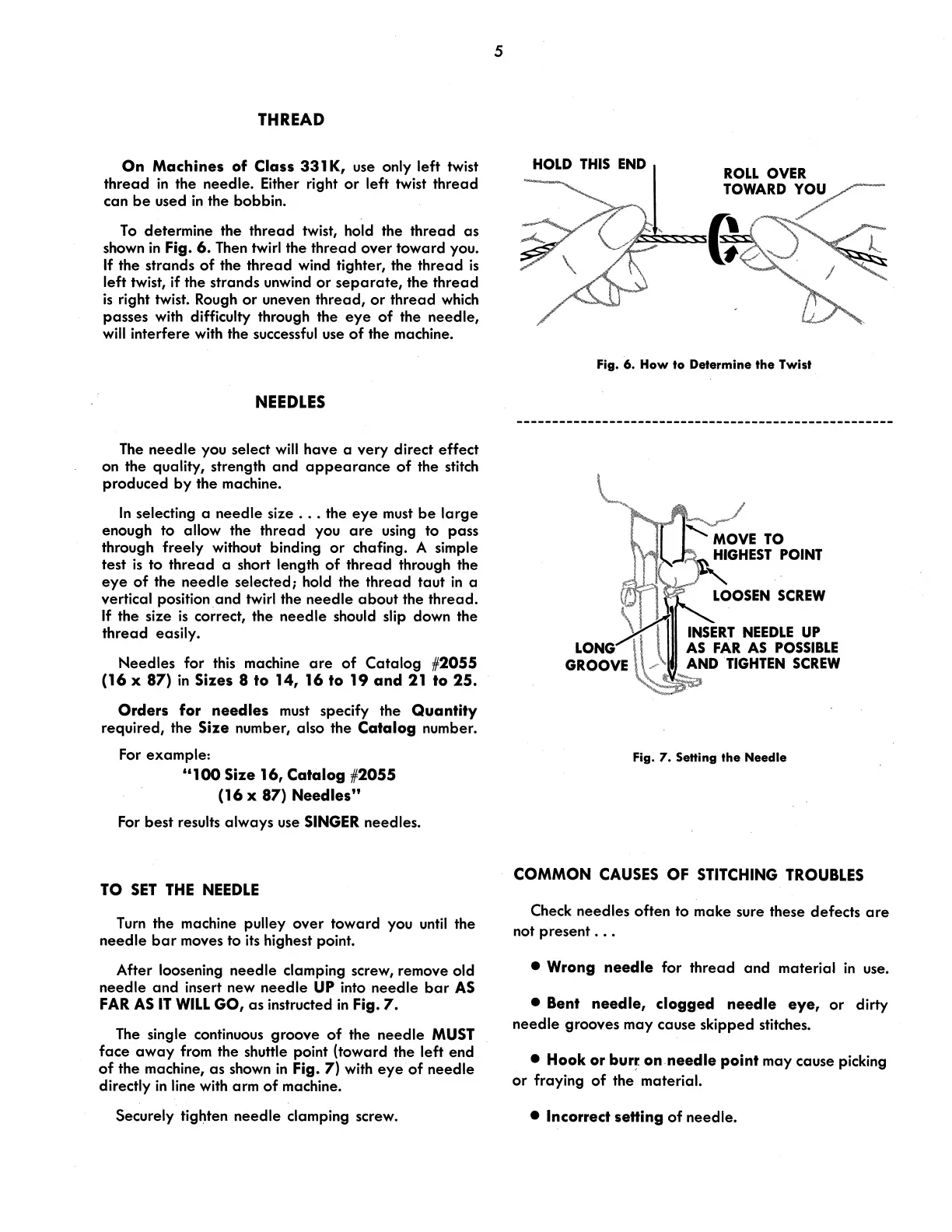

HOLD

THIS

END

Fig.

6.

How

to Determine the Twist

VE

TO

HEST

POINT

T

NEEDLE

UP

AR

AS

POSSIBLE

TIGHTEN

SCREW

Fig.

7.

Setting the Needle

COMMON

CAUSES

OF STITCHING

TROUBLES

Check needles often to make sure these defects

are

not present

...

• Wrong needle for

thread

and

material

in

use.

• Bent needle, clogged needle eye,

or

dirty

needle

grooves may cause skipped stitches.

• Hook or

bur~

on

needle point may cause picking

or

fraying

of

the material.

• Incorrect setting

of

needle.

Loading...

Loading...