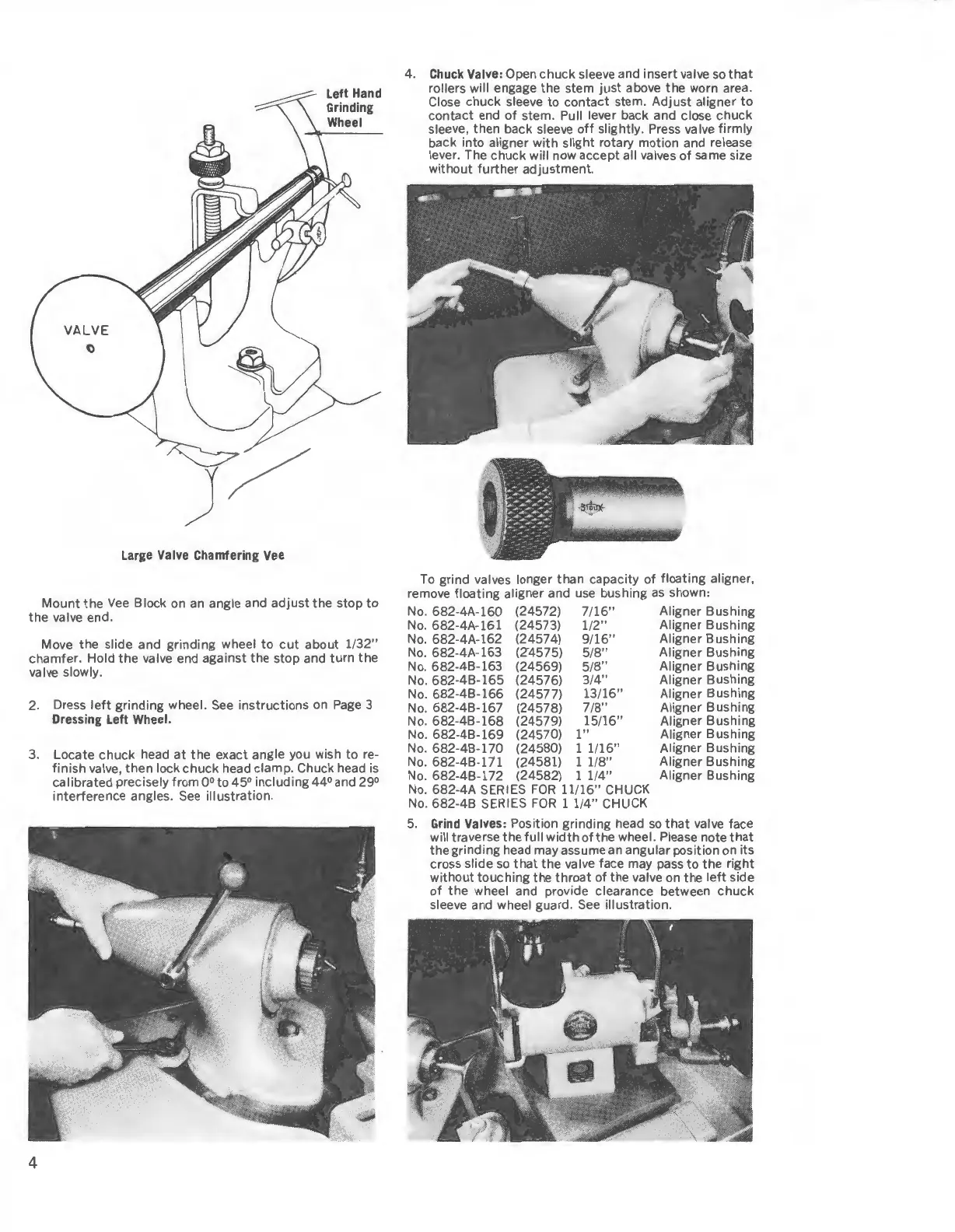

Large

Valve

Chamfering

Vee

Left

Hand

Grinding

Wheel

Mount

the

Vee

Block on

an

angle and

adjust

the stop

to

the valve end.

Move the slide and grinding wheel to

cut

about 1/

32"

chamfer. Hold the valve end against the stop and

turn

the

valve slowly.

2. Dress

left

grinding wheel.

See

instructions

on

Page

3

Dressing

Left

Wheel.

3.

Locate chuck head

at

the exact angle you wish to re-

finish valve, then lock chuck head clamp. Chuck head is

calibrated precisely from 0° to 45° including 44° and 29°

interference angles.

See

illustration.

4

4.

Chuck

Valve:

Open chuck sleeve and insert valve

so

that

rollers will engage the stem

just

above the worn area.

Close chuck sleeve

to

contact stem. Adjust aligner

to

contact end

of

stem. Pull lever back and close chuck

sleeve, then back sleeve

off

slightly. Press valve firmly

back into aligner

with

slight rotary motion and release

lever. The chuck will now accept all valves of same size

without

further

adjustment.

To

grind valves longer than capacity of floating aligner,

remove floating aligner and use bushing

as

shown:

No. 682-4A-160 (24572) 7/

16"

Aligner Bushing

No.

682-4A-161 (24573)

1/2"

Aligner Bushing

No.

682-4A-162 (24574)

9/16"

Aligner Bushing

No

. 682-4A-163 (Z4575) 5/8" Aligner Bushing

No

. 682-4B-163 (24569) 5/

8"

Aligner Bushing

No. 682-4B-165 (24576) 3/4" Aligner Bushing

No

. 682-4B-166 (24577)

13/16"

Aligner Bushing

No.

682-4B-167 (24578) 7/

8"

Aligner Bushing

No.

682-4B-168 (24579) 15/

16"

Aligner Bushing

No.

682-4B-169 (24570)

1"

Aligner Bushing

No. 682-4B-170 (24580) 1 1/

16"

Aligner Bushing

No

. 682-4B-171 (24581) 1 1/

8"

Aligner Bushing

No. 682-4B-172 (24582) 1

1/4"

Aligner Bushing

No. 682-4A SERIES

FOR

11

/

16"

CHUCK

No.

682-4B SERIES

FOR

1 1/

4"

CHUCK

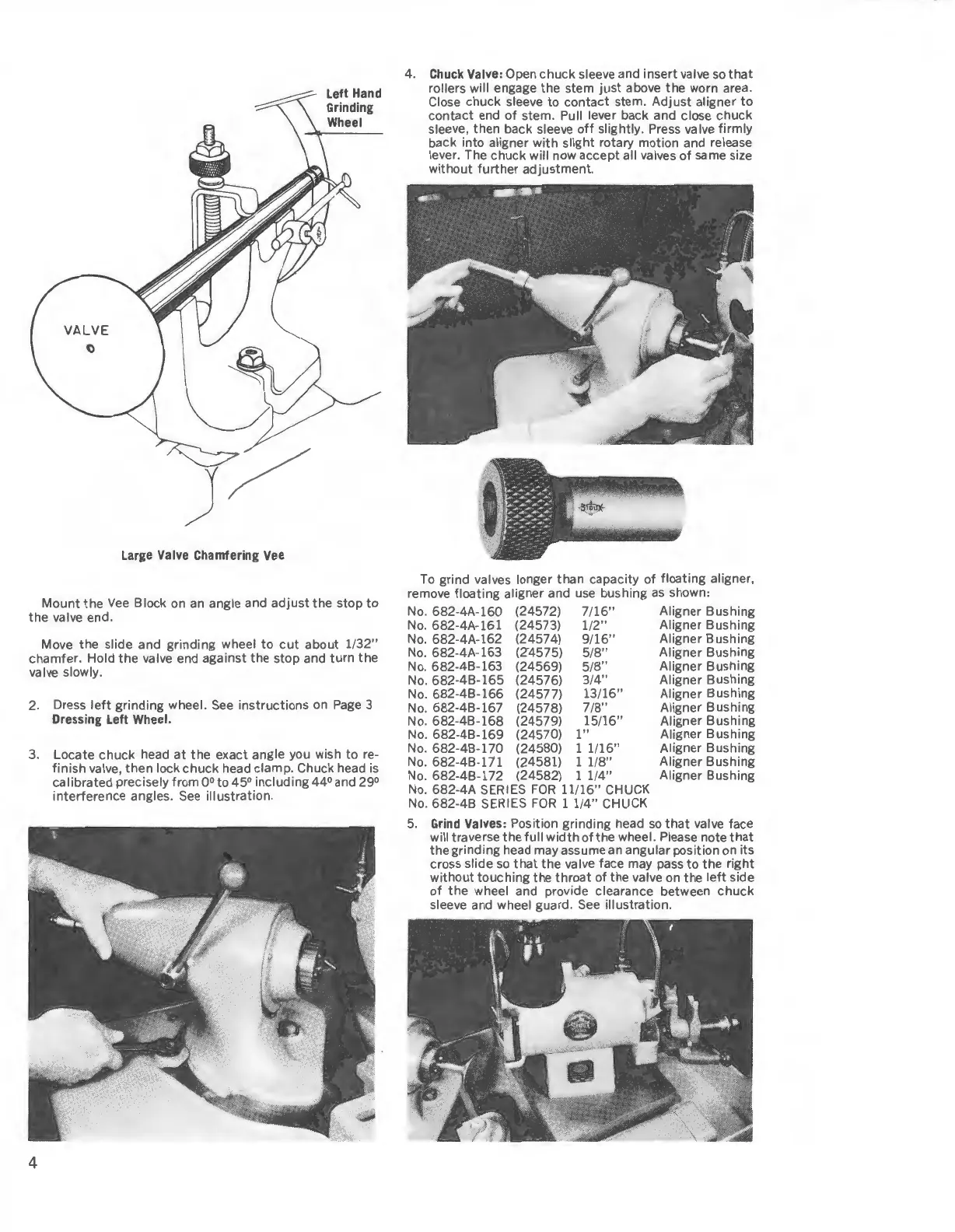

5.

Grind

Valves:

Position grinding head

so

that

valve face

will traverse the full

width

of the wheel. Please note

that

the grinding head

may

assume

an

angular position on its

cross slide

so

that

the valve face may pass

to

the

right

without touching the throat of the valve on the

left

side

of

the wheel and provide clearance between

chuck

sleeve and wheel guard.

See

illustration.

Loading...

Loading...