INSTRUCTIONS

Dressing

Left

Wheel

(Cat.

No's.

176 & 177)

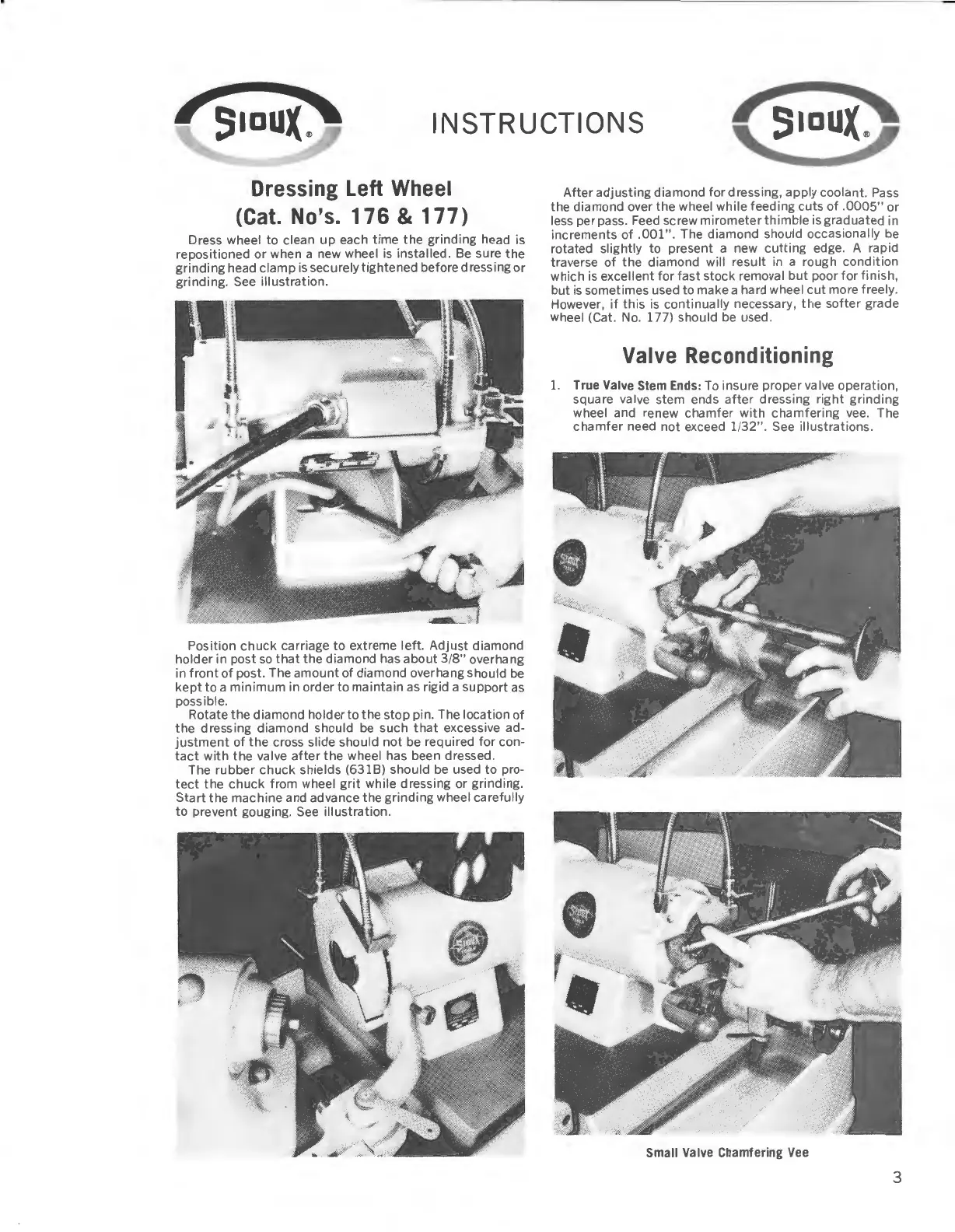

Dress wheel

to

clean

up

each

time

the

grinding

head

is

repositioned or when a new wheel

is

installed.

Be

sure

the

grinding

head

clamp

is

securely

tightened

before dressing or

grinding.

See

illustration.

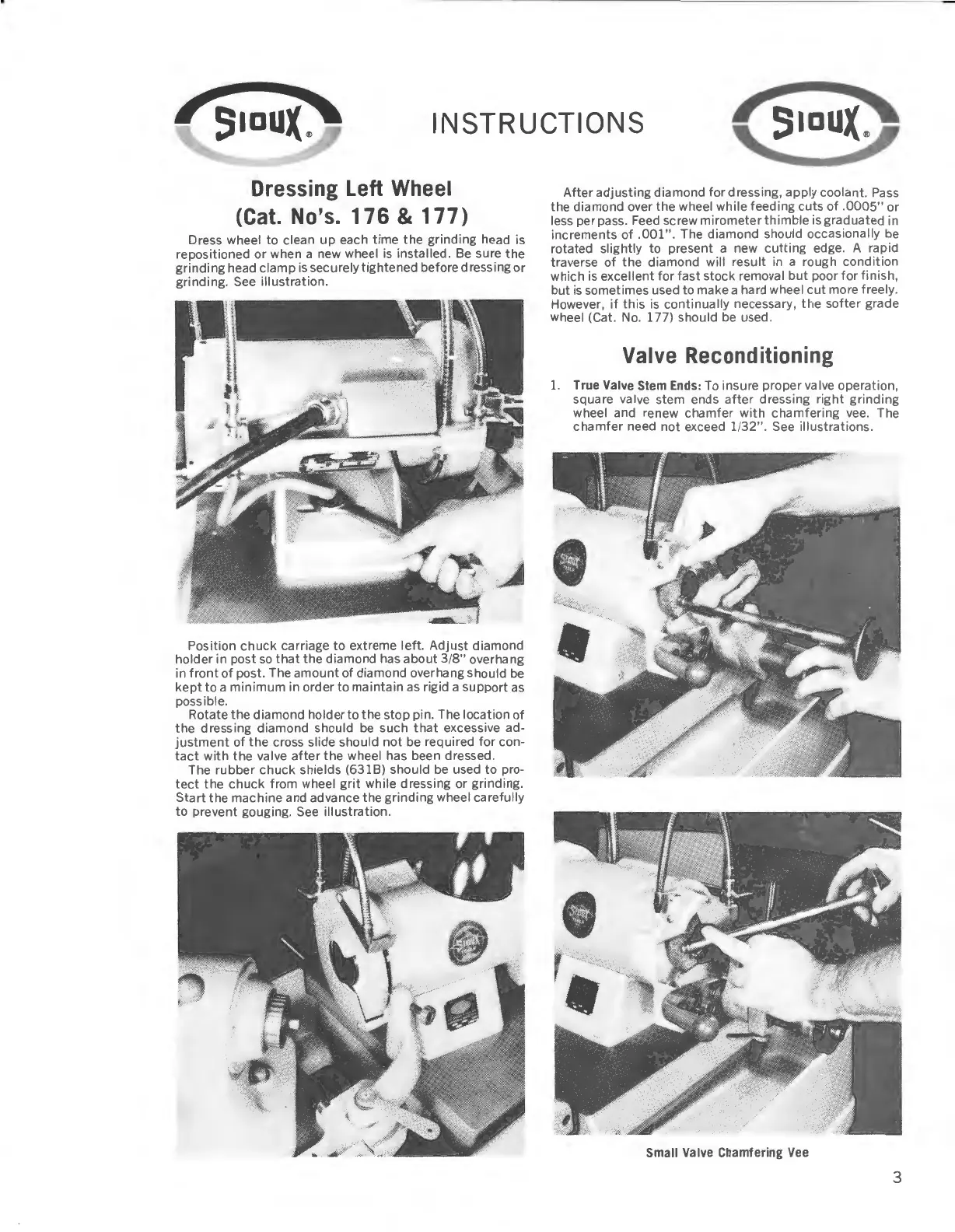

Position

chuck

carriage

to

extreme left.

Adjust

diamond

holder in post so

that

the

diamond has

about

3/

8"

overhang

in

front

of

post. The

amount

of

diamond overhang should

be

kept

to

a

minimum

in order

to

maintain

as rigid a support

as

possible.

Rotate

the

diamond holder

to

the

stop pin. The location

of

the

dressing diamond should

be

such

that

excessive ad-

justment

of

the

cross slide should

not

be

required

for

con-

tact

with

the

valve

after

the

wheel has been dressed.

The

rubber

chuck

shields

(6318)

should be used

to

pro-

tect

the

chuck

from wheel

grit

while dressing or grinding.

Start

the

machine

and advance

the

grinding

wheel carefully

to

prevent gouging. See illustration.

After

adjusting

diamond

for

dressing, apply coolant. Pass

the

diamond over

the

wheel while feeding

cuts

of

.

0005"

or

less per pass. Feed screw

mirometer

thimble

is

graduated in

increments

of

.001"

. The diamond should occasionally

be

rotated slightly

to

present a new

cutting

edge. A rapid

traverse

of

the

diamond will result in a rough

condition

which

is

excellent

for

fast

stock removal

but

poor

for

finish

,

but

is

sometimes used

to

make a hard wheel

cut

more freely.

However,

if

this

is

continually necessary,

the

softer

grade

wheel (Cat. No. 177) should

be

used.

Valve

Reconditioning

1.

True

Valve

Stem

Ends:

To insure proper valve operation,

square

valve stem ends

after

dressing

right

grinding

wheel and renew

chamfer

with

chamfering

vee. The

chamfer

need

not

exceed 1/

32"

. See

illustrations

.

Small

Valve

Chamfering

Vee

3

Loading...

Loading...