If relubrication is needed, the relubrication

intervals can be estimated following the

method explained under the Lubrication

chapter of SKF General Catalogue.

The SKF ConCentra ball bearing units

have a grease fitting with different threads:

1/4-28 UNF for units metric shafts (all •

sizes) and for inch shafts size 1˝

1/8 NPT for units inch shafts sizes larger •

than 1˝

The 1/4-28 UNF thread can be changed to

G 1/4 using an LAPN 1/4 28 UNF adapter.

Relubrication procedure

When relubricating, grease should be

pumped slowly into the bearing as it rotates,

until fresh grease starts to escape from

the seals.

NOTE: Excessive pressure from pumping

too quickly may damage the seals.

Greases for Relubrication

To relubricate SKF ConCentra ball bearings

SKF LGWA 2, LGMT 2 or LGMT 3 greases

can be used. Each of these greases is fully

compatible with the original grease filled in

the factory.

Storing SKF ConCentra ball

bearing units

Because they are treated with a rust

preventive compound, SKF ConCentra

ball bearings can be stored in their original

unbroken package for a number of years

provided the relative humidity of the

storeroom does not exceed 60% and there

are no great fluctuations in temperature.

When stored for an extended period, these

ball bearing units may have a higher initial

torque than a newer unit. If not stored in

their original packaging, SKF ConCentra ball

bearings and SKF ConCentra ball bearing

units should be well protected from

moisture and contaminants.

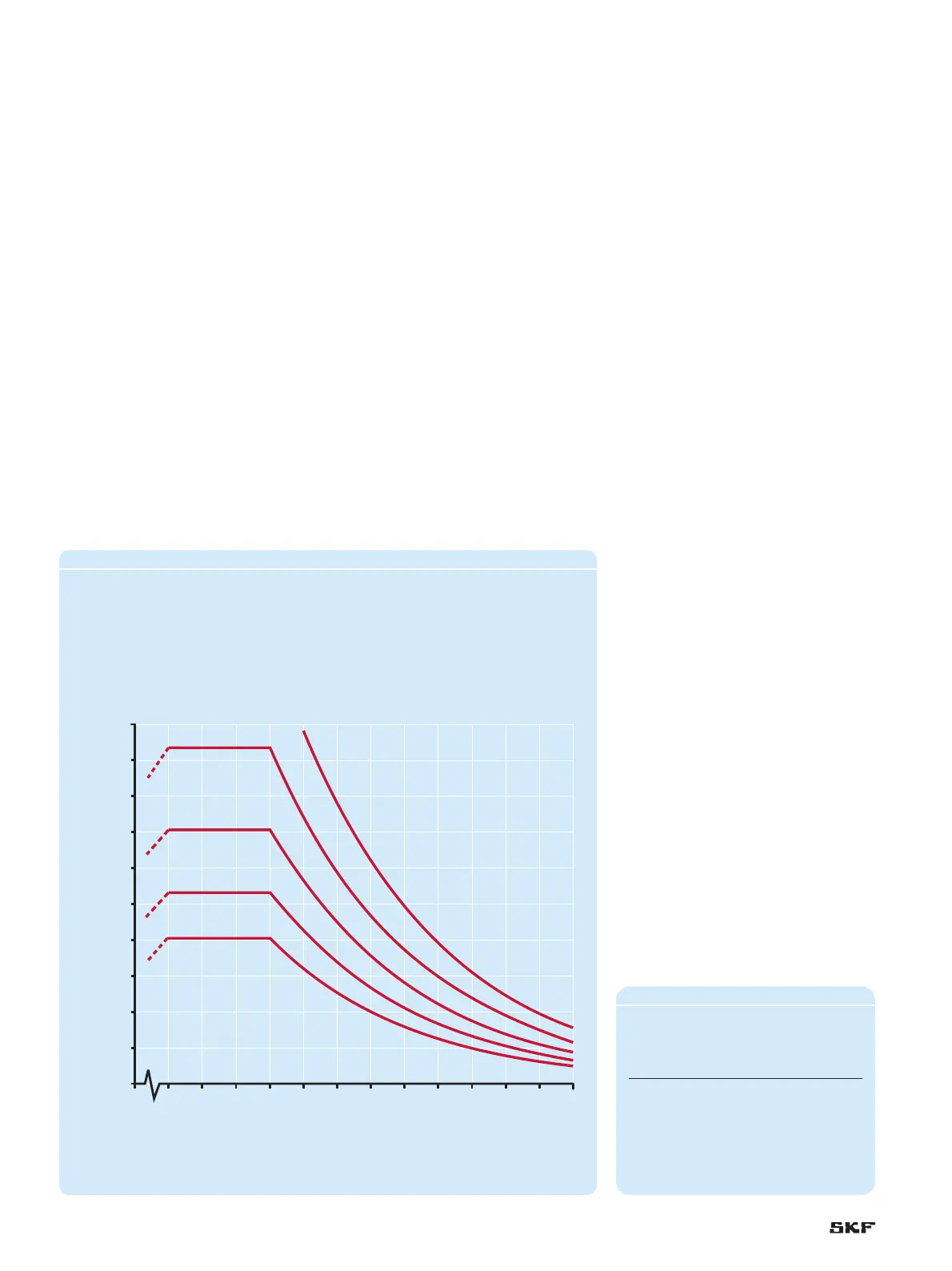

Diagram 1

Service life of the grease fill in SKF ConCentra ball bearing units

as a function of

the operating temperature, °C•

the rotational speed n, r/min•

the bearing mean diameter dm, mm (• † table 2)

100 000

90 000

80 000

70 000

60 000

50 000

40 000

30 000

20 000

10 000

0

0 40 45 50 55 60 65 70 75 80 85 90 95 100

n × d

m

= 250 000

200 000

150 000

100 000

50 000

t

f

, operating hours

Operating temperature, °C

Table 3

Reduction factor for the grease life,

depending on the load

Load P

Reduction factor

≤ 0,05 1

0,1 C 0,7

0,125 C 0,5

0,25 C 0,2

16

Loading...

Loading...