Align the shaft in the bearing arrange-6

ment axially and, if possible, turn it a few

times.

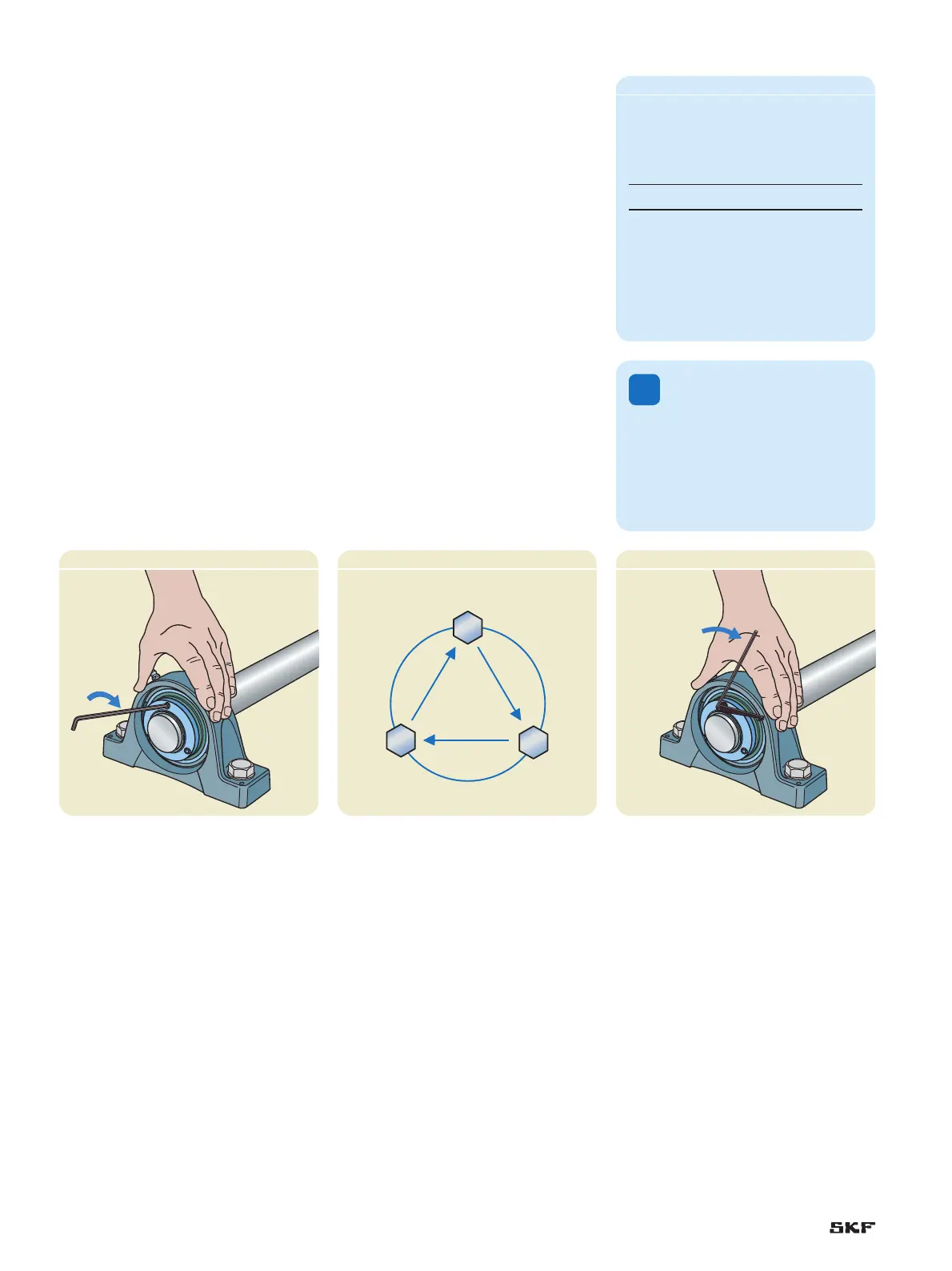

Start to secure the first bearing unit to 7

the shaft by positioning the collar so that

a grub screw is directly opposite the split

in the sleeve. Tighten the screws finger-

tight, holding the short leg of the supplied

hexagonal key († fig. 4).

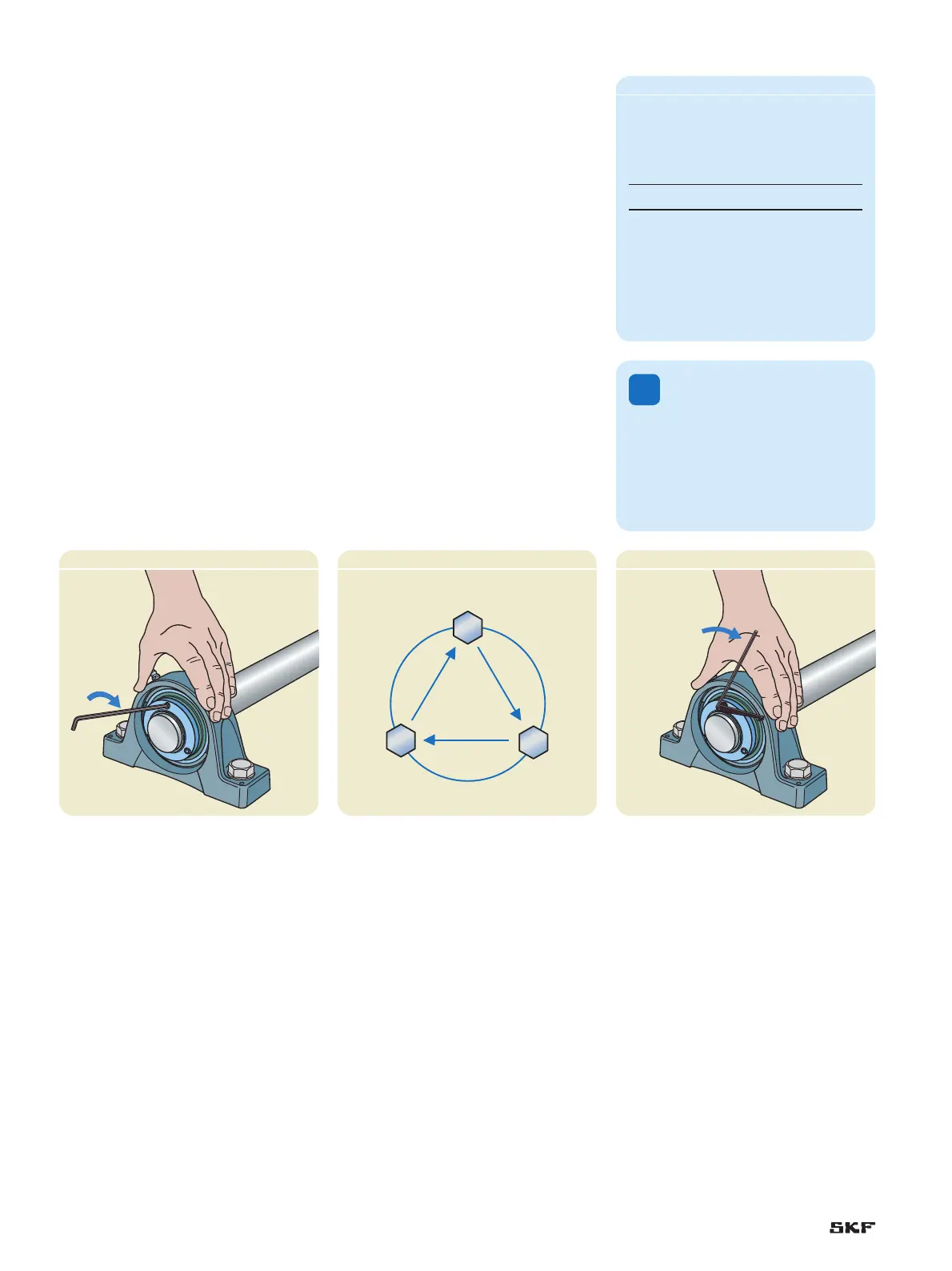

Tighten the screws 1/4 turn following the 8

tightening pattern in fig. 5. Do this twice.

Then tighten each set screw, starting with

the screw opposite the split in the sleeve,

until the long end of the hexagonal key

comes in contact with the supplied torque

indicator († fig. 6) or to the recom-

mended torque value shown in table 2.

Dismounting instructions

Table 2

Recommended tightening torque values

Bearing size

1)

Screw

size

Recommended

torque

from to high

–

Nm / in.lbf

05 06 M5 4,2 / 37

07 13 M6 7,4 / 66

1)

For example: bearing size 07 includes all bearings based

on a Y 207 e.g. YSP 207 SB-2F, YSP 207-104 SB-2F,

YSP 207-106 SB-2F, YSP 207-107 SB-2F

!

Caution: Do not use auxiliary

equipment such as a hammer or

pipe to tighten the screws.

Secure the second bearing unit to the 9

shaft following steps 7 and 8. Make

sure the shaft turns smoothly and the

bearings are not jammed. If the shaft

does not turn smoothly, loosen one

of the bearing units following the

dismounting instructions and secure

it again.

If applicable, snap the end cover in 10

place.

Loosen and remove the attachment bolts 4

and slide the unit off the shaft.

Repeat the 5 steps 1 to 4 for the second

unit.

It may be necessary to clean the shaft ex-1

tension with emery cloth to remove rust

or repair surface damage.

Loosen the screws on the first unit.2

Lightly tap the sleeve edge on the mount-3

ing collar side of the bearing until the

locking system releases the shaft. As an

alternative, tap on the bearing inner ring

side face on the side opposite the collar.

Fig. 5

Fig. 6

18

Loading...

Loading...