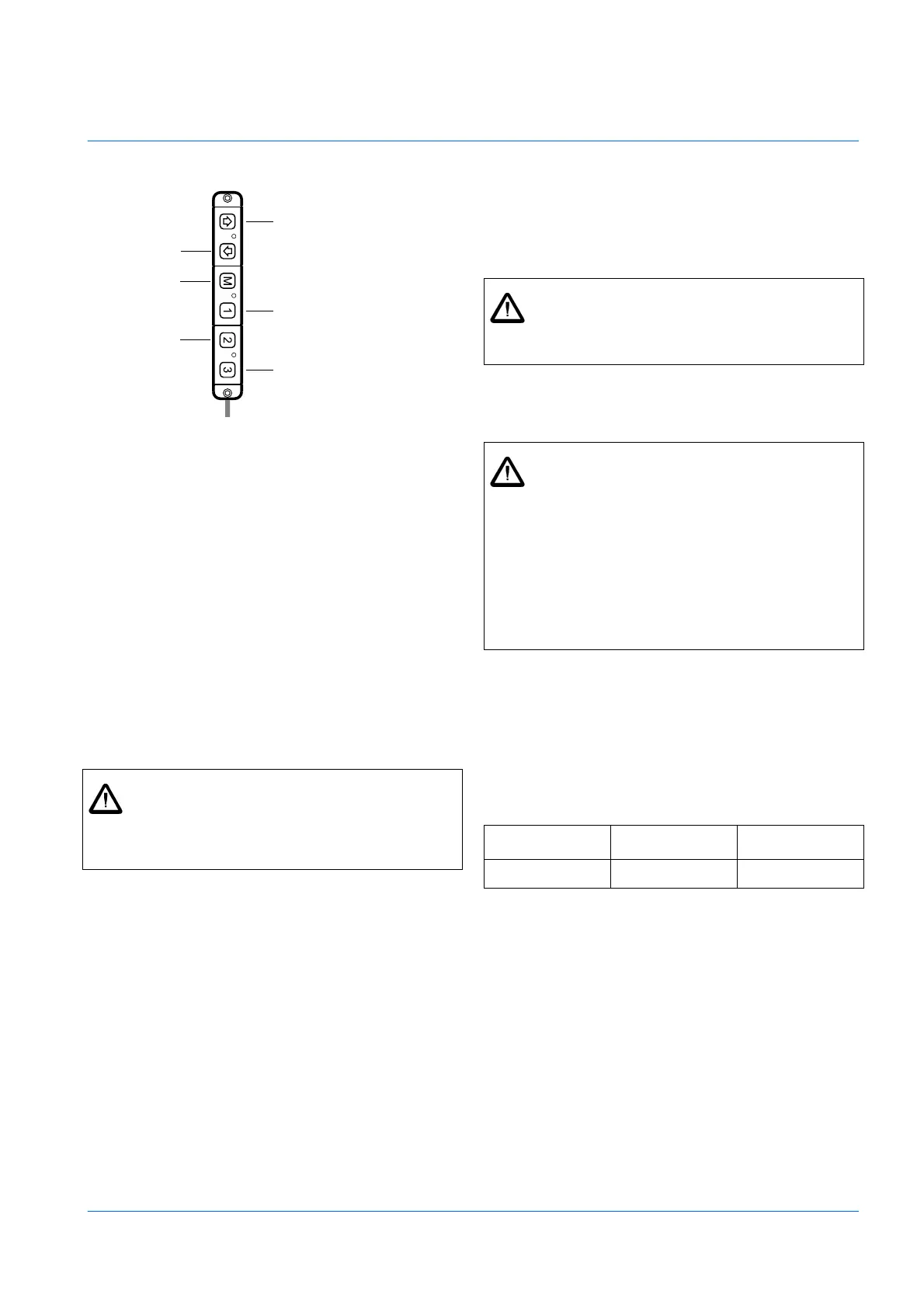

Fig. 2

Memory for 1 actuator

Setting the memory functions

1. Move the actuators to the basic position:

a) The actuators must be moved in the counter-load direction as

far as the end position (reference point).

2. Storing the memory position:

a) Move the actuators to the memory position.

b) Hold down the 'M' button on the handswitch and, at the same

time, press the '1' button.

c) Release both buttons simultaneously to end the memory

storage operation.

d) Repeat steps a) to c) for positions '2' and '3'.

3. Calling up a memory position:

a) To call up the stored positions, press the appropriate position

button.

b) For example:

To move to position 1, press button '1'.

To move to position 2, press button '2'.

To move to position 3, press button '3'.

All the actuators always move simultaneously to the

stored position.

If the actuators are not moved to the reference position

before the required positions are stored, this can be

initiated by pressing the memory button 'M'.

Technical Data

Refer to Flyer 530D, 2950/55.

Ambient Conditions

Operation:

•

Temperature 10 °C to 40 °C

•

Max. air humidity 85 %

Storage/transport:

•

Temperature –20 °C to +40 °C

•

Max. air humidity 95 %

•

Do not expose the desk switch to adverse weather conditions.

Cleaning

Protection from water, cleaning, disinfection

The IPX0 degree of protection is only guaranteed is only effective

when the desk switch is properly connected. The control unit is not

suitable for use with machine washing devices.

It is important to prevent any fluids from penetrating the

desk switch.

The plastic housing must be inspected periodically (every

6 months) for signs of mechanical damage (cracks).

The desk switch should be cleaned as soon as possible after use,

in order to prevent the accretion of unwanted material.

•

The desk switch should be cleaned with a damp cloth and

water, to which isopropyl alcohol has been added

.

The Magnetic Special Instructions ML 0111/87 must be

observed.

Washing water containing chemical additives must be

pH-neutral.

Excessively acidic or alkaline washing water can cause

irreparable damage to the metal and plastic parts of the

control unit.

High pressure steam cleaning machines must not be

used.

Only isopropyl alcohol should be used for wiping over the

desk switch to disinfect it.

Maintenance

The housing and the cables connected to it must be examined at

regular intervals (every 6 months) for signs of mechanical damage.

If there is any damage, the complete desk switch must be

replaced.

Troubleshooting

Fault Cause Remedy

Desk switch does

not operate

Poor plug-in

connection

Check the plug-in

connections

•

Observe the instructions in the relevant Customer

documentation and the specific control unit documents.

•

If in doubt, contact the Magnetic Service Department

personnel.

Loading...

Loading...