Section 04 ENGINE

Sub-Section 05 (CDI SYSTEM)

04-05-3

NOTE : The following procedures can be

done without removing the engine from

chassis. To facilitate magneto removal, hold drive

pulley with tool (P / N 529 0276 00).

CLEANING

Clean all metal components in a non-ferrous met-

al cleaner.

CAUTION : Clean stator and magneto us-

ing only a clean cloth.

DISASSEMBLY

2,5, Magneto and Magneto Flywheel Nut

To gain access to magneto assembly, remove the

following parts as needed on different engines :

– muffler

– rewind starter

– starting pulley

To remove magneto flywheel retaining nut :

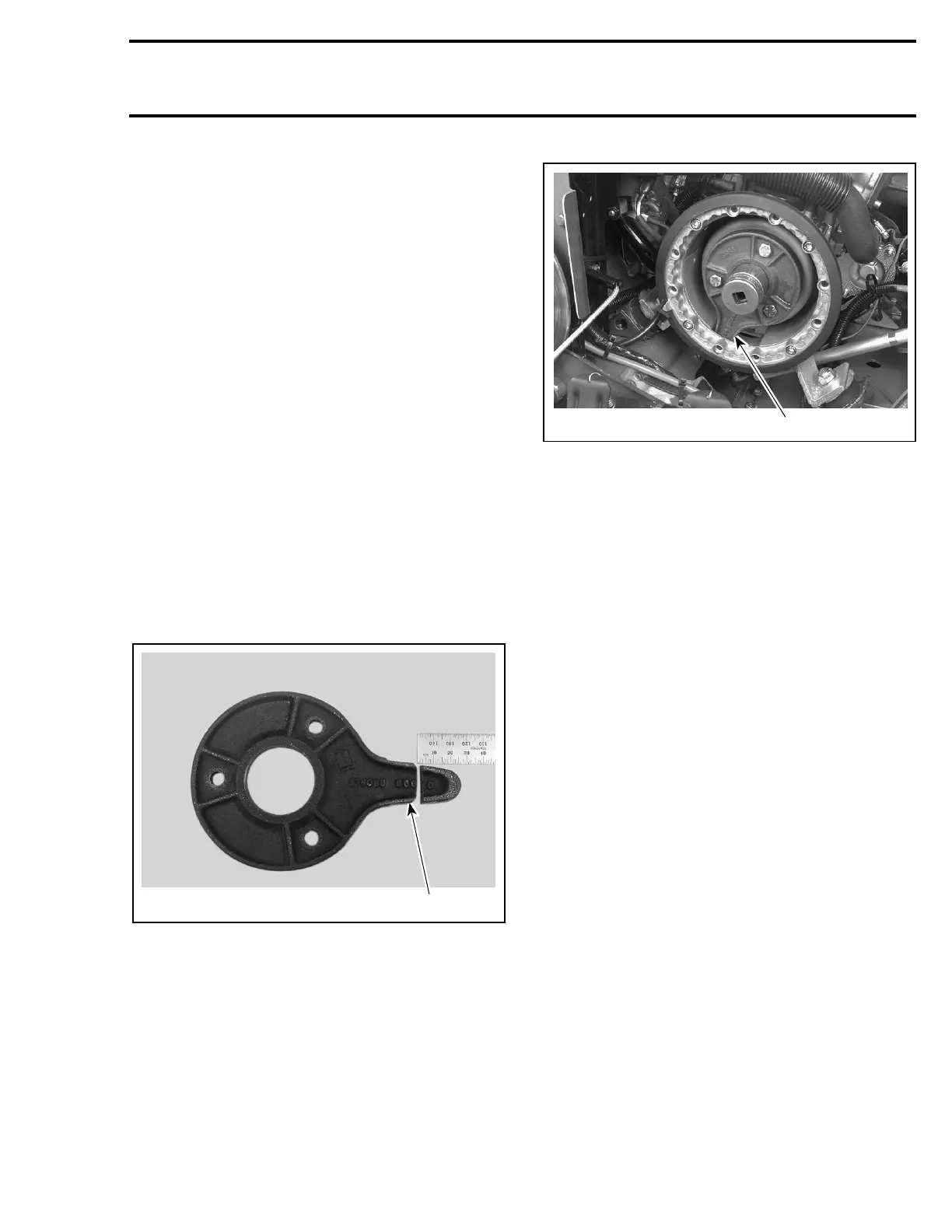

Use magneto puller ring (P / N 420 8760 80) mod-

ified as shown.

1. Cut by 25 mm (1 in)

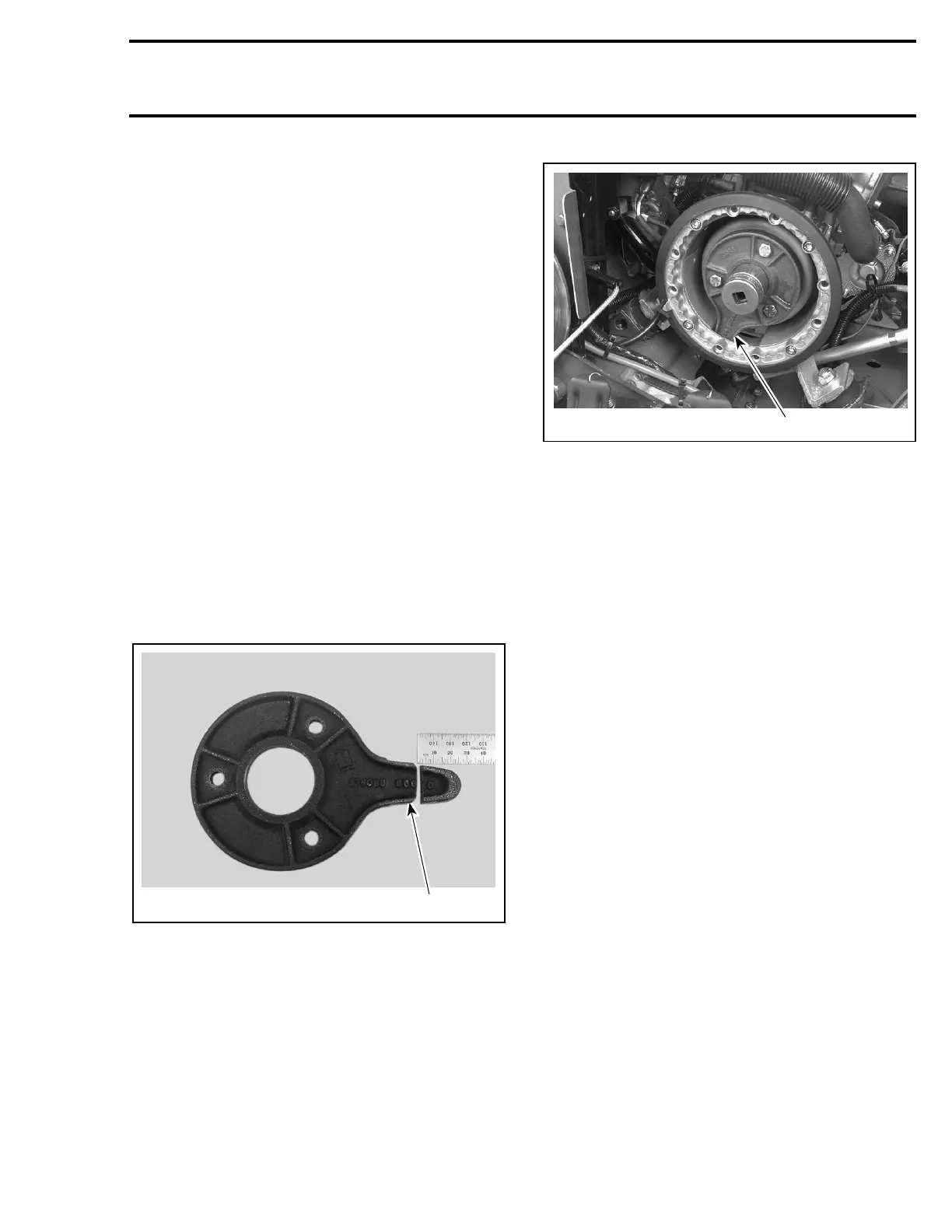

Install puller with its tab in magneto housing open-

ing.

TYPICAL

1. Tab in magneto housing opening

– Remove magneto flywheel nut, using a 30 mm

socket machined to 40 mm (1.580 in) outside

diameter by 16 mm (5/8 in) long.

NOTE : To correctly remove a threadlocked

fastener it is first necessary to tap on the fas-

tener to break threadlocker bond. This will elimi-

nate the possibility of thread breakage.

To remove magneto flywheel, install the suitable

puller as shown.

– Tighten puller bolt and at the same time, tap on

bolt head using a hammer to release magneto

flywheel from its taper.

4, Hydro Damper Ass’y

Check for oil leaks and for noisy ring inside. Re-

placed it in both cases.

6,7, Trigger Coil and Screw

Magneto and stator plate must be removed be-

fore trigger coil removal.

To replace trigger coil :

– Disconnect trigger coil connector housing.

– Remove grommet from crankcase where trig-

ger coil wire exits magneto housing.

– Remove retaining screws.

– Remove trigger coil and carefully pull wires.

– Thread magneto harness through crankcase

hole before trigger coil harness.

'

A06E23A

1

Loading...

Loading...