Section 04 ENGINE

Sub-Section 05 (CDI SYSTEM)

04-05-4

1. Magneto harness through crankcase hole

– Install new trigger coil and other parts re-

moved.

Adjustment

Whenever the trigger coil or the magneto fly-

wheel is removed or replaced, the air-gap be-

tween the trigger coil and the flywheel protrusion

must be checked and adjusted. The purpose of

this adjustment is to obtain the minimum clear-

ance between these parts – without touching at

any RPM – so that the trigger coil produces its

proper electrical output. Ignition timing must also

be checked. Refer to IGNITION TIMING 06-02

then look for Checking Ignition Timing.

CAUTION : Each time trigger coil air-gap

is adjusted, ignition timing must be

checked.

Proceed as follows :

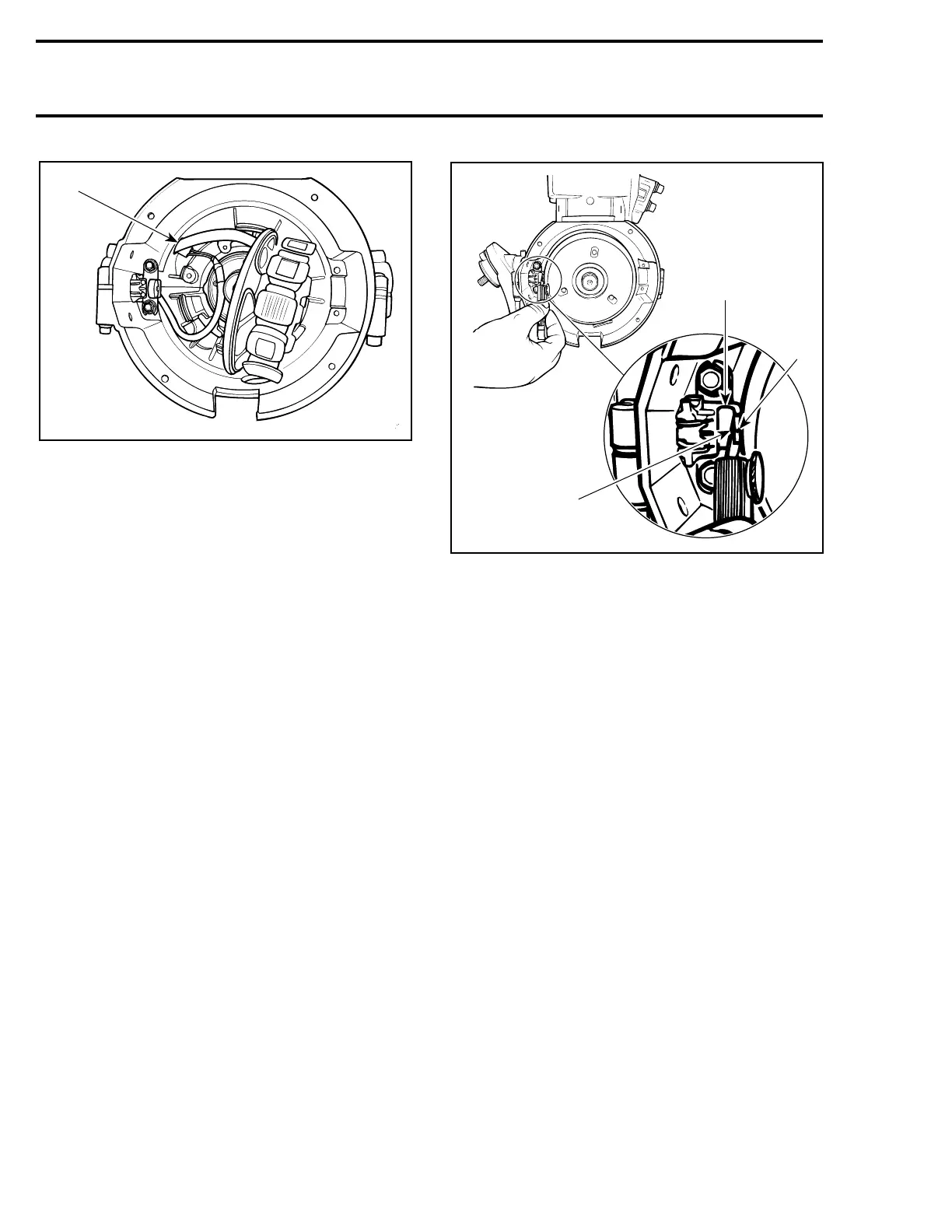

1. Rotate flywheel so that the protrusion aligns

with trigger coil.

2. Using a feeler gauge of 0.75 mm (.030 in) min.

0.55 mm (.022 in) and max. 1.45 mm (.057 in)

thick, check air-gap between center pole of trig-

ger coil and flywheel protrusion.

3.If necessary, adjust by slackening retaining

screws and moving trigger coil toward or away

of protrusion.

4. Retighten screws and recheck air-gap.

ADJUSTING TRIGGER COIL AIR-GAP

1. Trigger coil

2. Flywheel protrusion

3. Measure at center pole of trigger coil 0.75 mm (.030 in)

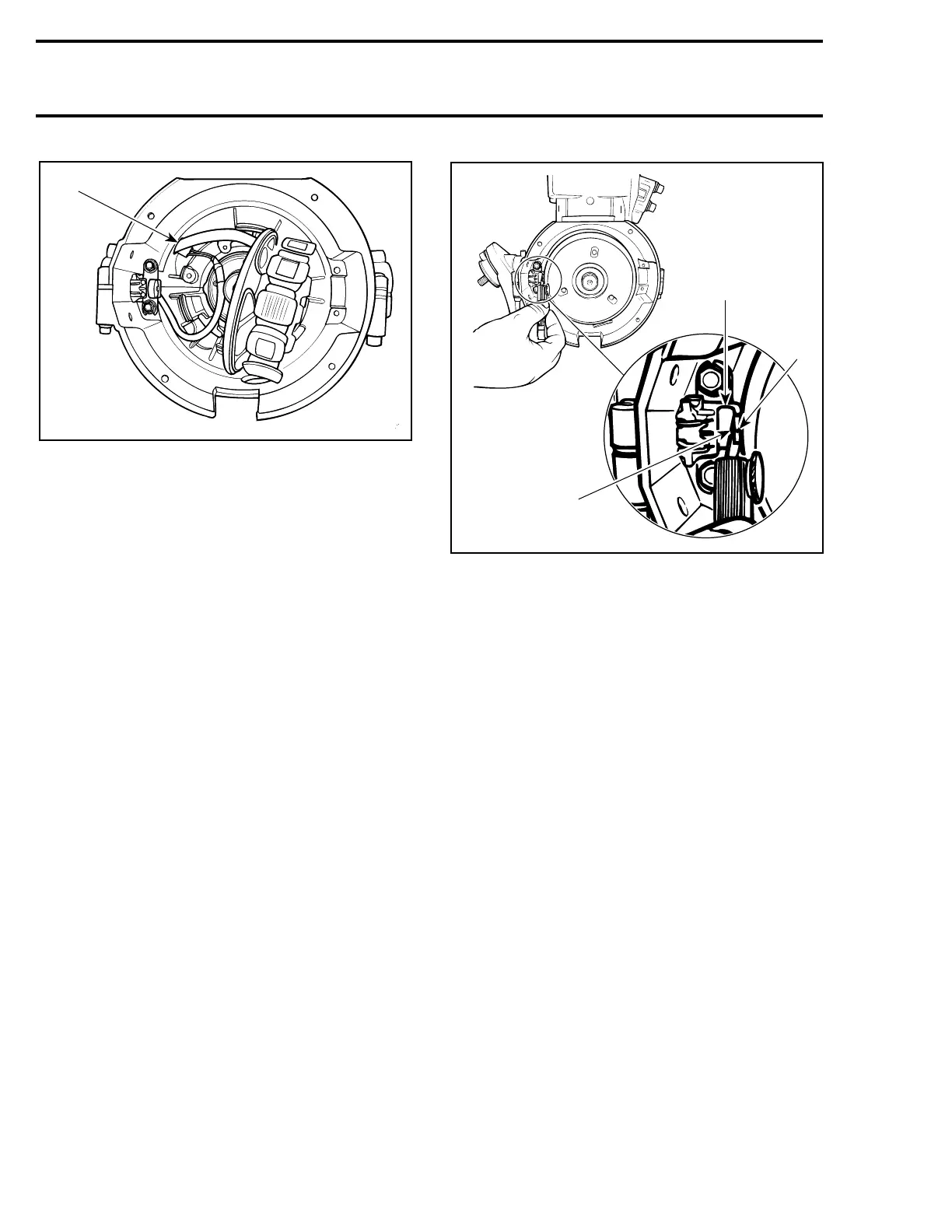

1, Stator

To replace stator :

– Disconnect the 3-wire connector (BLACK, RED

and BLACK / RED wires).

– Disconnect both YELLOW wires.

– Remove grommet from crankcase where mag-

neto harness exits magneto housing.

– Remove stator plate retaining screws.

– Remove stator plate with stator and carefully

pull wires.

– Install new parts and other parts removed tak-

ing care not to squeeze trigger coil harness.

A25E1AA

1

A15E0NA

2

3

1

Loading...

Loading...