Section 04 ENGINE

Sub-Section 10 (REWIND STARTER)

04-10-3

CAUTION : It is of the utmost importance

that the rewind starter spring(s) be lubri-

cated periodically using specific lubricants.

Otherwise, rewind starter component life will

be shortened and / or rewind starter will not

operate properly under very cold tempera-

tures.

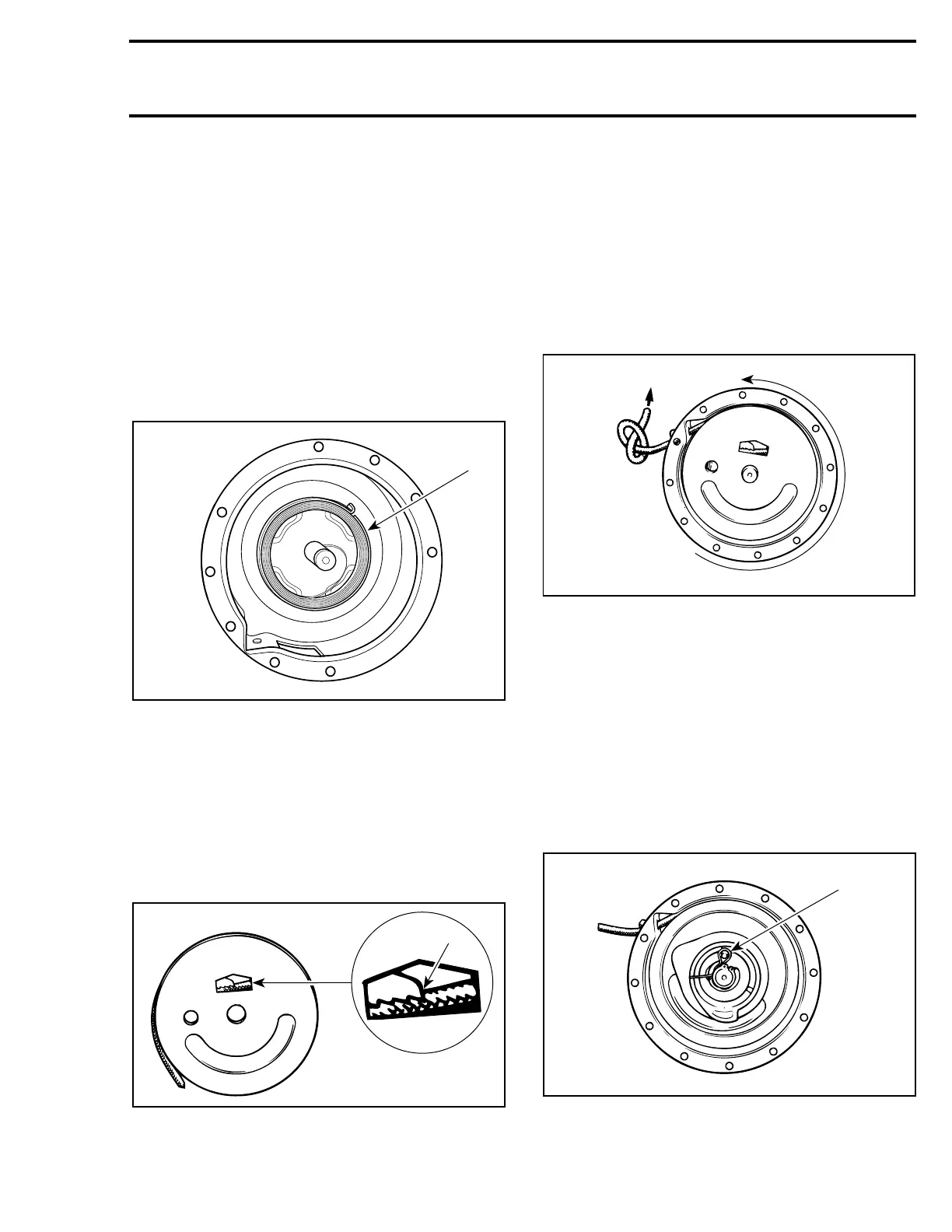

Lubricate spring assembly with silicone com-

pound grease (P / N 420 8970 61) and position

into starter housing as illustrated.

CAUTION : This lubricant must NOT be

used on rewind starter locking spring as it

does not stay on under vibration.

1. Grease inside spring guide

CAUTION : The use of standard multi-

purpose grease could result in rewind

starter malfunction.

5,6,7, Rope Sheave, Starter Rope and

Key

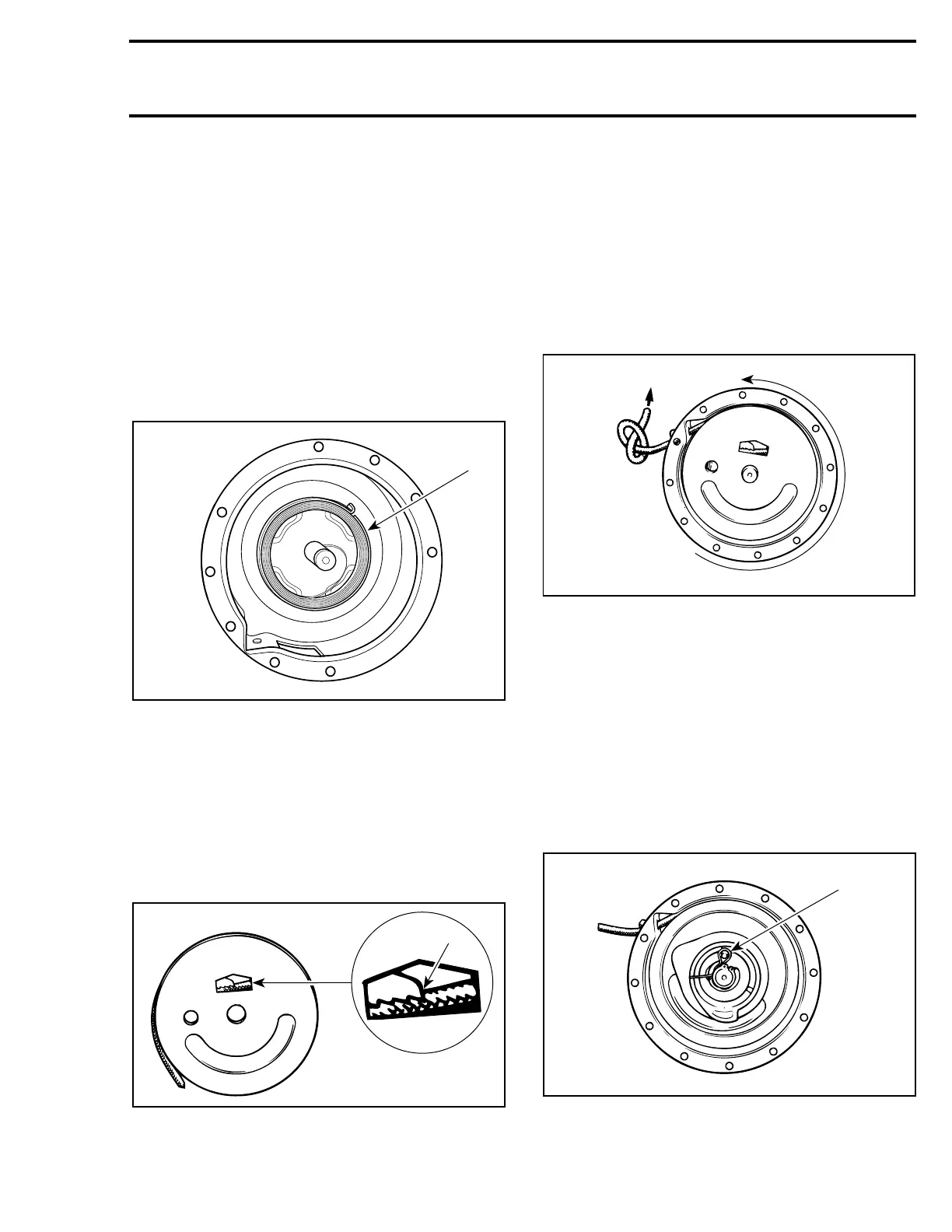

To install a new rope : insert rope into sheave ori-

fice and lock it with the key as illustrated.

1. Push to lock

To adjust rope tension :

Wind rope on sheave and place rope sheave into

starter housing making sure that the sheave hub

notch engages in the rewind spring hook.

Rotate the sheave counterclockwise until rope

end is accessible through starter housing orifice.

Pull the rope out of the starter housing and tem-

porarily make a knot to hold it. One turn preload

will give 7 turns of tension when fully extended.

1. Knot

8,9,10, Pawl, Pawl Lock and Circlip

Apply silicone compound grease (P / N 420 8970

61) to pawl and pawl lock.

Position pawl, pawl lock and circlip.

11,17, Locking Spring and Molykote G-

n Paste

Install locking spring and lubricate with

MOLYKOTE G-n paste from Dow Corning

®

or

equivalent.

1. Molykote G-n paste inside spring

A01C14A

1

Loading...

Loading...