Section 04 ENGINE

Sub-Section 02 (454, 583 AND 670 ENGINE TYPES)

04-02-4

NOTE : The following procedures can be

done without removing the engine from

chassis.

CLEANING

Discard all gaskets and O-rings.

Clean all metal components in a non-ferrous met-

al cleaner.

Scrape off carbon formation from cylinder ex-

haust port, cylinder head and piston dome using a

wooden spatula.

NOTE : The letters “AUS” (over an arrow

on the piston dome) must be visible after

cleaning.

Clean the piston ring groove with a groove cleaner

tool, or with a piece of broken ring.

DISASSEMBLY

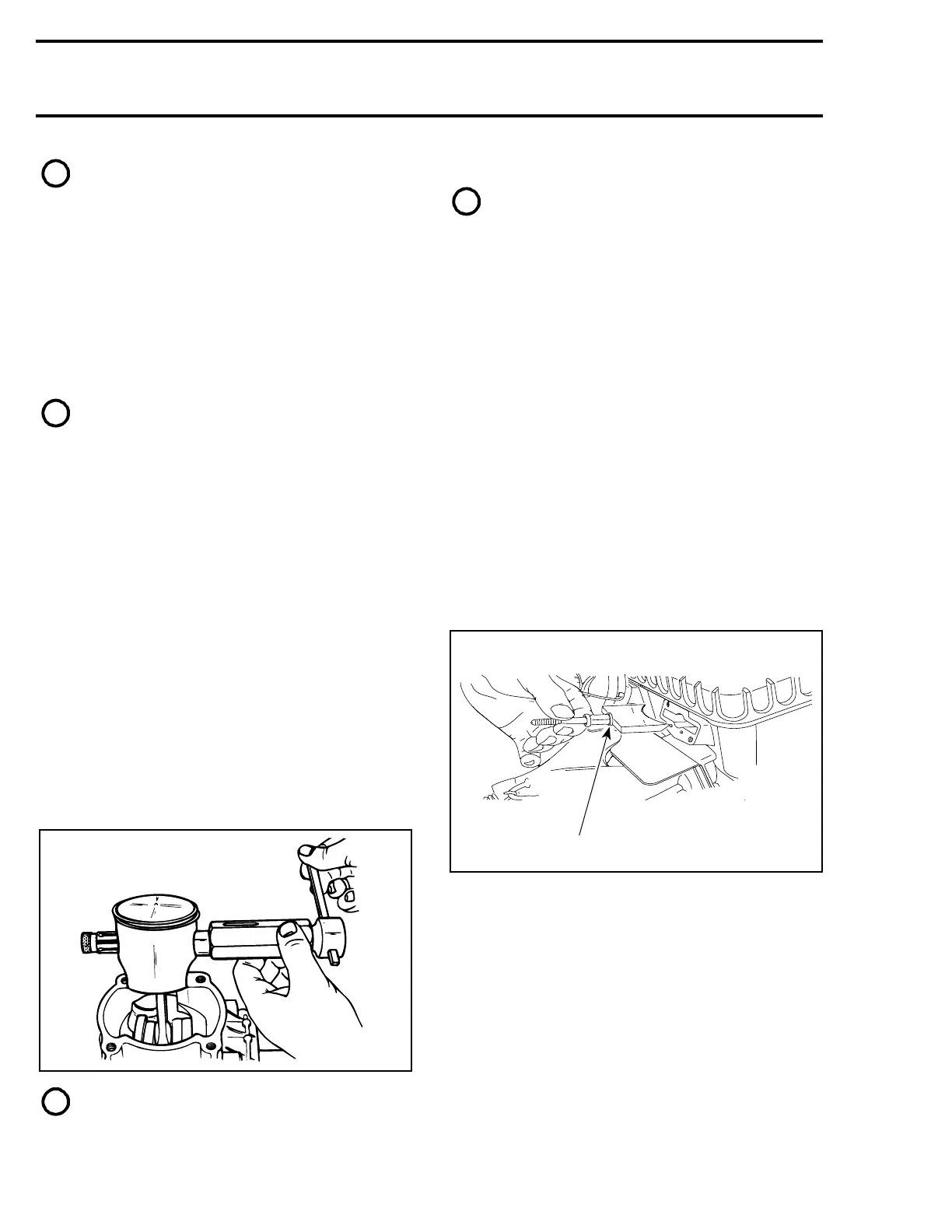

22,23,24, Piston Pin, Circlip and Piston

Place a clean cloth over crankcase then with a

pointed tool inserted in piston notch, remove cir-

clip from piston.

To remove piston pin, use piston pin puller (P / N

529 0290 00) as follows :

– Fully screw puller handle.

– Insert puller end into piston pin.

– Install adaptor (P / N 529 0236 00) then screw

extracting nut (LH threads).

– Hold puller firmly and rotate puller handle coun-

terclockwise to pull piston pin.

NOTE : 0.25 mm oversize piston and rings

are available if necessary.

RAVE System

NOTE : RAVE stands for Rotax Adjustable

Variable Exhaust.

3,5,6, Spring Clip, Cover and Spring

Remove spring clip, cover and spring.

7,8, Valve Piston and Clamp 50 mm

Cut clamp and unscrew valve piston.

9,10, Bellows and Clamp 21 mm

Spread clamp and remove bellows.

11,12,13, Cylindrical Screw, Lock

Washer and Valve Rod Housing

Remove cylindrical screws and their washers

then valve rod housing.

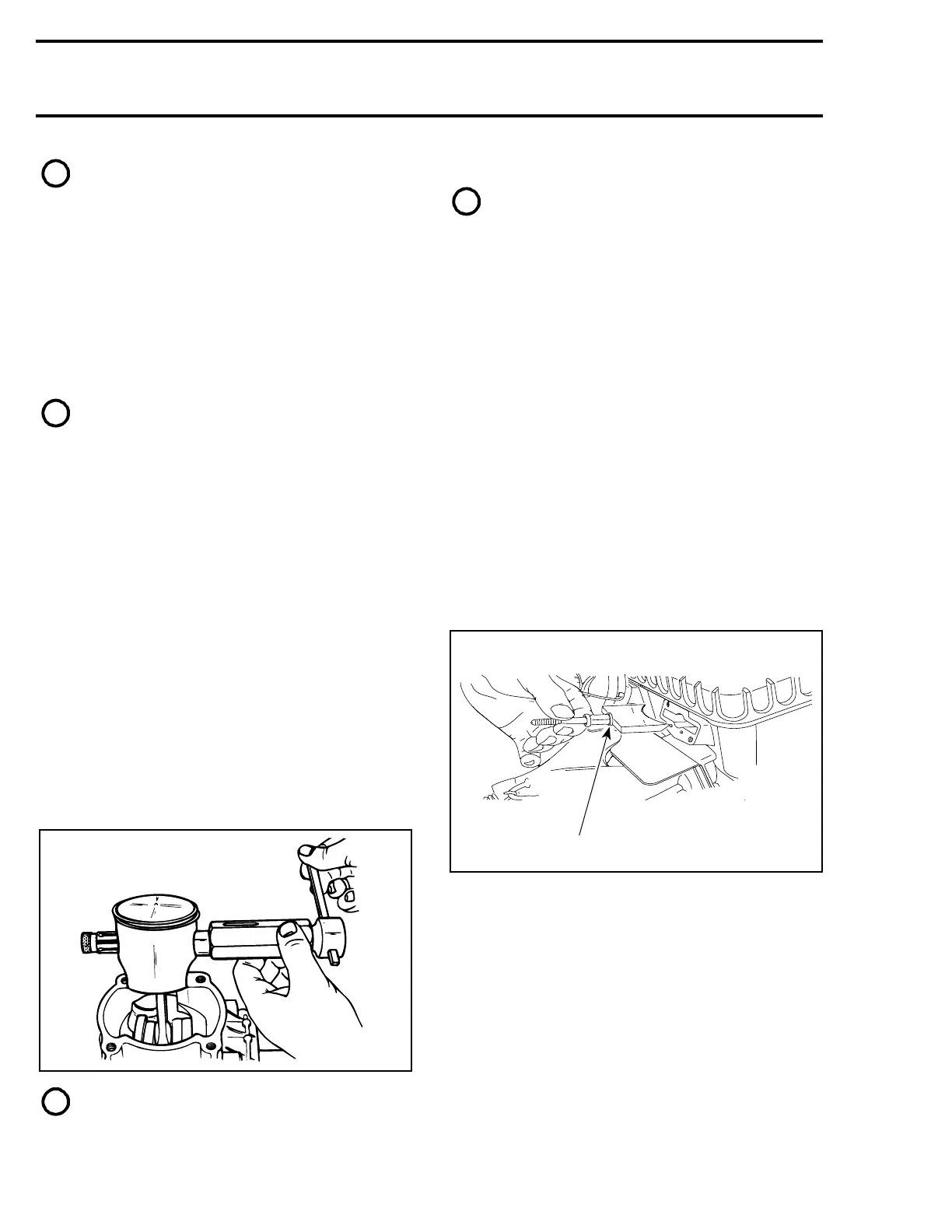

15,17,18,19,20, Valve Rod, O-ring,

Washer, Distance Nut and Exhaust

Valve

Pull out exhaust valve assembly.

1. Exhaust valve ass’y

583 Engine Only

Do not disassemble exhaust valve ass’y need-

lessly. Secure valve in a soft jaw vice. Remove O-

ring and washer, unscrew distance nut and re-

move washer. Unscrew valve rod from distance

nut.

INSPECTION

All Models

See ENGINE DIMENSIONS MEASUREMENT 04-

04.

A24C04A

1

Loading...

Loading...