Section 04 ENGINE

Sub-Section 02 (454, 583 AND 670 ENGINE TYPES)

04-02-5

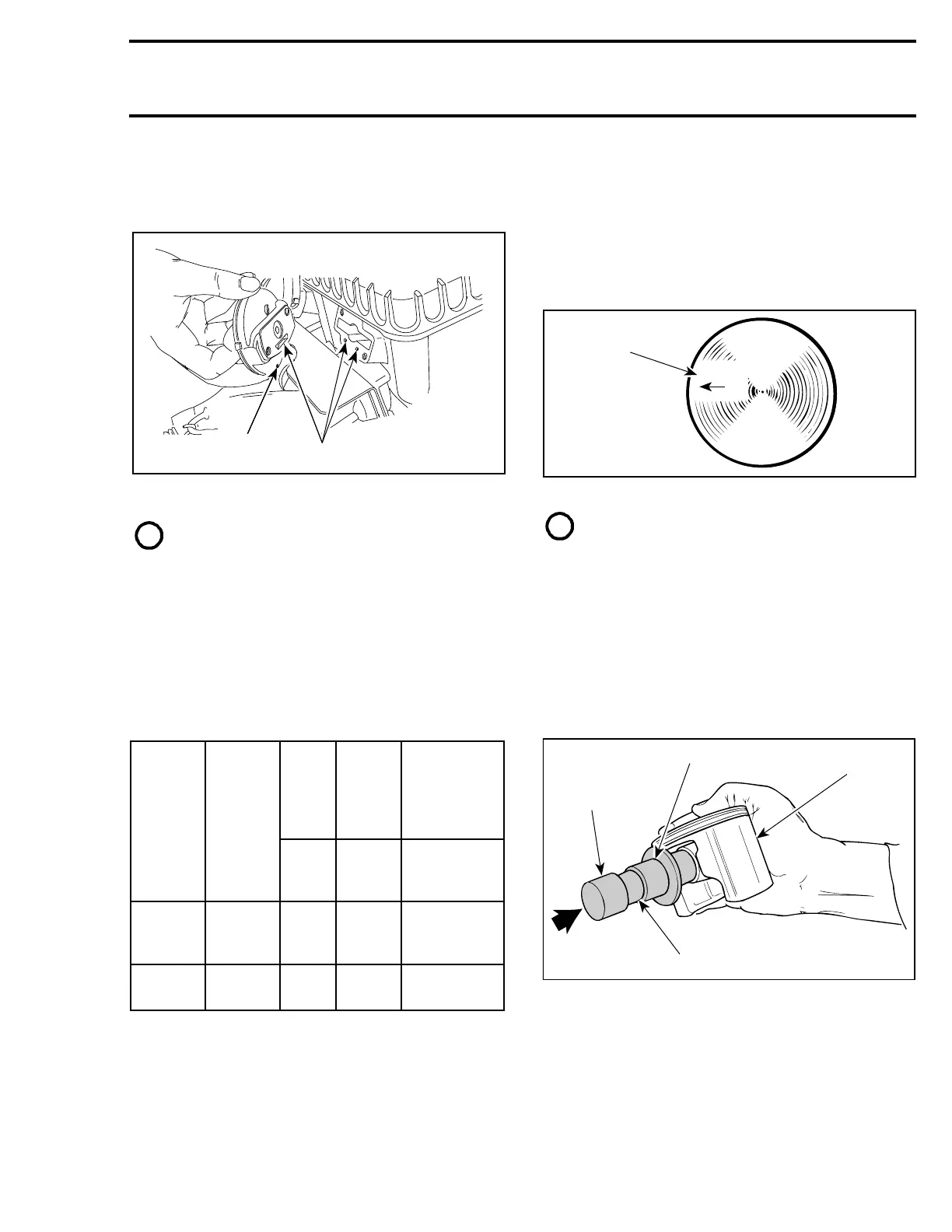

RAVE System

Check valve rod housing and cylinder for clogged

passages.

1. Draining hole

2. Passages

NOTE : Oil dripping from draining hole indi-

cates a loosen clamp or damaged bellows.

4, Valve Rod

Check valve rod for straightness.

10, Bellows

Check for cracked, dried or perforated bellows.

13, Spring

Make sure both springs installed on the engine

have same characteristics.

ASSEMBLY

22,23,24, Piston Pin, Circlip and Piston

At assembly, place the pistons over the connect-

ing rods with the letters “AUS” (over an arrow on

the piston dome) facing in direction of the exhaust

port.

1. Exhaust

NOTE : Spare parts pistons and cylinders

are identified with a green or red dot, it is

important to match the piston with the cylinder of

the same color.

Use piston pin puller (P / N 529 0210 00) to ease

piston pin installation.

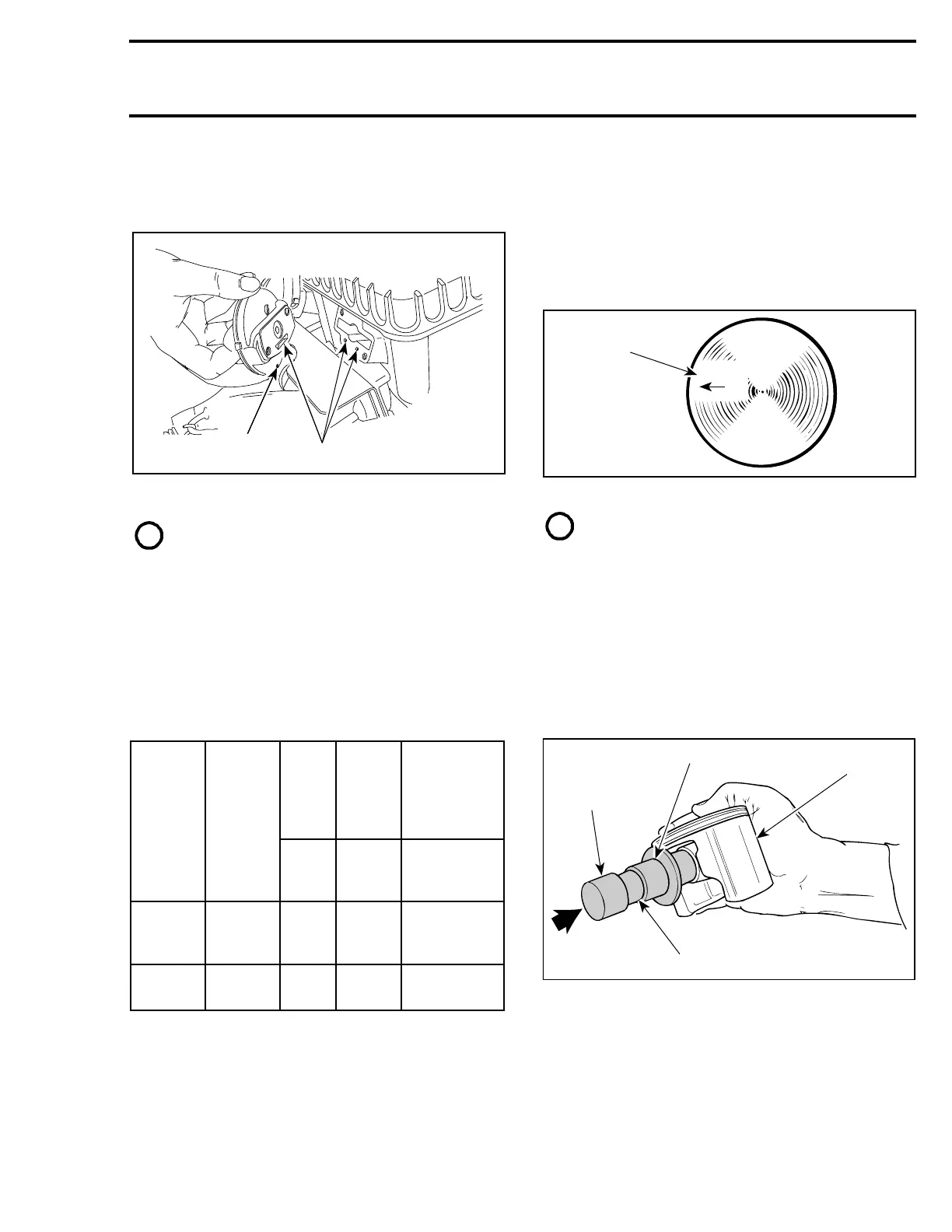

To minimize the effect of acceleration forces on

circlip, install each circlip so the circlip break is at

6 o’clock as illustrated. Use piston circlip installer

(P / N 529 0169 00) for all engines except 670 and

(P / N 290 8770 16) for 670 engine.

1. Place circlip in

2. Restrain

3. Oil

ENGINE

TYPE

SPRING

P / N

WIRE

DIA.

FREE

LENGT

H

PRELOAD IN

N (LBF) AT

COM-

PRESSED

LENGTH

mm

(in)

mm

(in)

OF

14.7 mm

(.579 in)

454

420

2399 45

1.0

(.039)

48.5

(1-29/

32)

20.3

(4.55)

583 and

670

420

2399 48

1.0

(.039)

38.0

(1-1/2)

19.3

(4.34)

1

2

A24C05A

Loading...

Loading...