Operating Instructions

-7-

Assembly

SELECTING BITS

A wide assortment of router bits with different

profiles are available as accessories.

To prevent personal injury.

Always remove the plug from

power source before removing or installing

bits or accessories.

INSTALLING AND REMOVING BITS

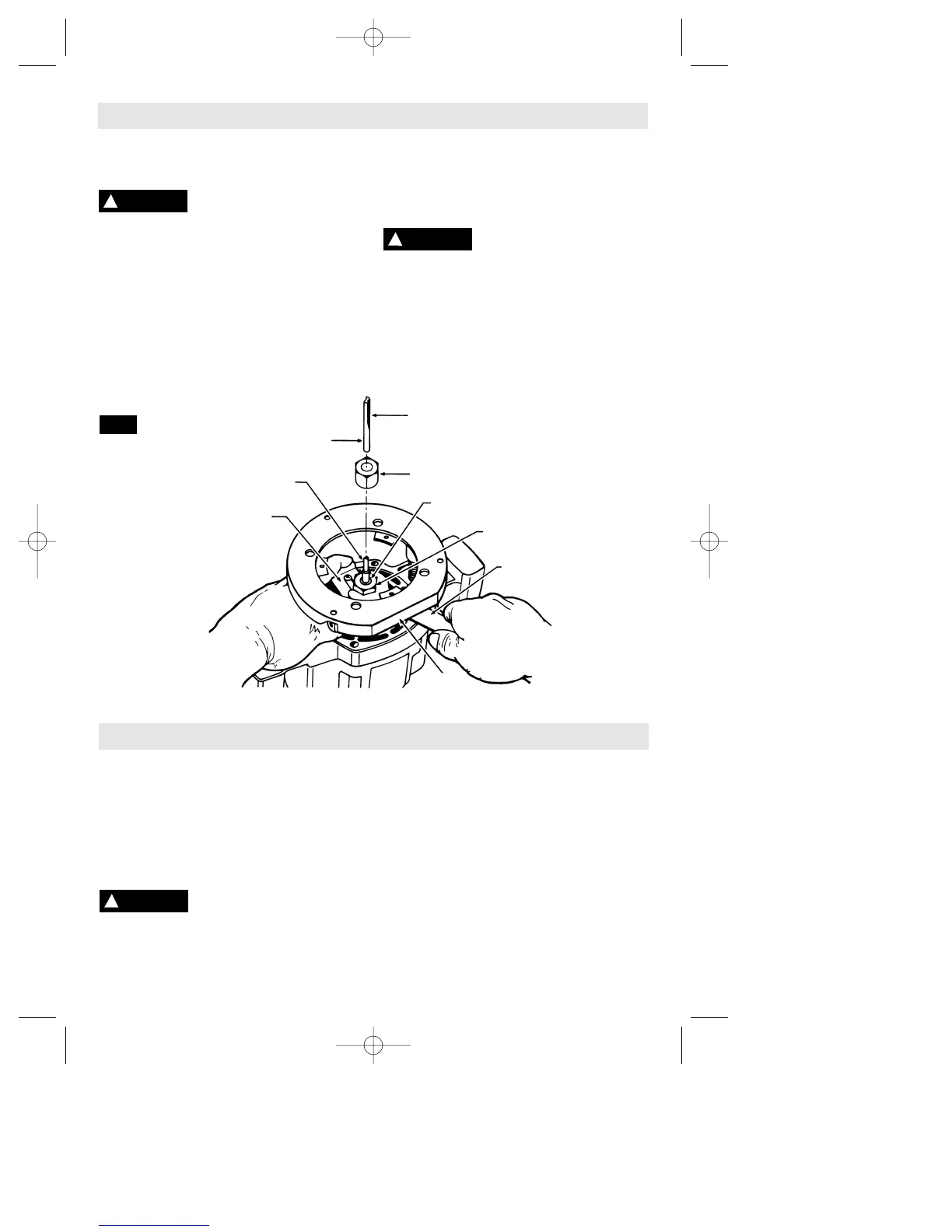

1. Place router upside down as shown in (Fig.

2), or lay router on its side with the flat side of

base resting on the bench.

2. Press collet lock to stop rotation of collet

nut. NOTE: it may be necessary to rotate

collet nut to engage collet lock.

3. With the wrench provided, turn collet nut

counterclockwise to loosen.

4. Insert bit three fourths into the collet, and

securely tighten collet nut clockwise with the

wrench provided.

To prevent damage to tool,

do not tighten collet nut

without a bit.

REMOVING BITS

Repeat steps 1, 2 and 3 of above and remove

bit.

ATTENTION: Be sure that the diameter of the

bit shank is the same size as the inside

diameter of the collet — your router is

equipped with a 1/4" collet.

!

WARNING

CHIP DEFLECTOR

The chip deflector helps keep dust and chips

out of your face. To remove, press inward on

center of deflector until it releases from tab in

base and lift out. To attach, place deflector

into position as shown in (Fig. 1). Then flex

sides of deflector while pushing down until

tab on base snaps into slot on deflector.

Safety glasses must always

be worn.

Skil plunge routers are designed for speed,

accuracy and convenience in performing

cabinet work, routing, fluting, beading, cove-

cutting, dove tails, etc. It will enable you to

accomplish inlay work, decorative edges and

many types of special carving.

PLUNGING ACTION

The plunge feature simplifies depth

adjustments and will allow the cutting bit to

easily and accurately enter the workpiece. To

lower, loosen lock lever (Fig. 1), and apply

downward pressure until depth gauge makes

contact with the fine depth adjustment screw,

and tighten lock lever. Loosen lever and

WRENCH

COLLET

COLLET NUT

BIT

SHANK

BIT

COLLET

LOCK

BASE

FIG. 2

!

CAUTION

!

WARNING

COLLET NUT

Loading...

Loading...