-9-

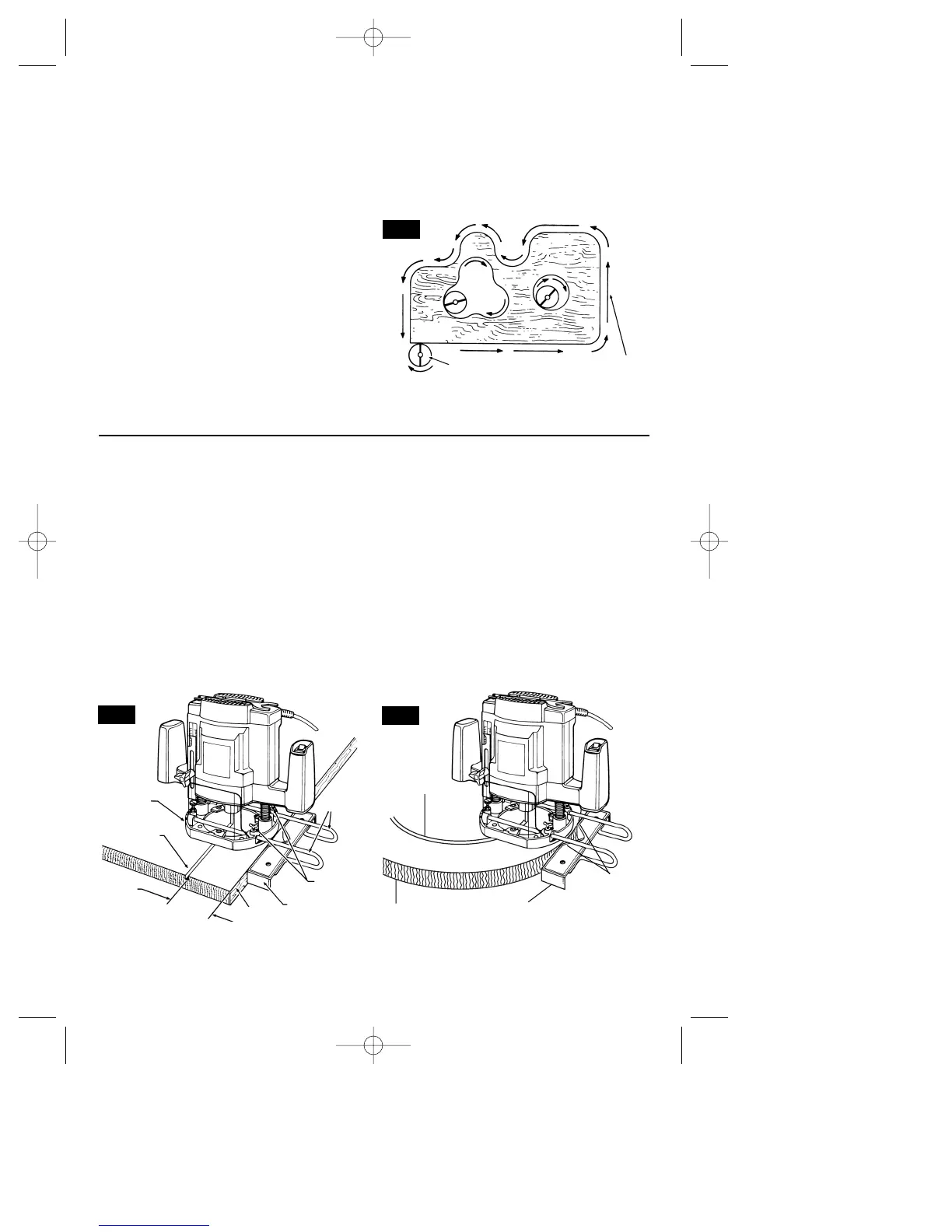

FEEDING THE ROUTER

As seen from the top of the router, the bit

turns clockwise and the cutting edges face

accordingly. Therefore, the most efficient cut

is made by feeding the router so that the bit

turns into the work, not away. Figure 4 shows

proper feed for various cuts. How fast you

feed depends on the hardness of the wood

and the size of the cut. For some materials,

several cuts of increasing depth are required.

As a general rule, it is best to pull the router

— not push. You get greater visibility, cleaner

cut, more control and less flying sawdust.

If the router is hard to control, heats up, runs

very slowly or leaves an imperfect cut,

consider these causes:

1. Wrong direction of feed — hard to control.

2. Feeding too fast — overloads motor.

3. Dull bit -— overloads motor.

4. Cut is too large for one pass — overloads

motor.

5. Feeding too slow — leaves friction burns

on work.

Feed smoothly and steadily (do not force).

You will soon learn how the router sounds

and feels when it is working best.

FIG. 4

CUTTER

WORK

DIRECTION

OF ROUTER

FEED

GUIDING ROUTER

The router can be guided through the work in

any of several ways. The method you use

depends, of course, on the demands of the

particular job and on convenience.

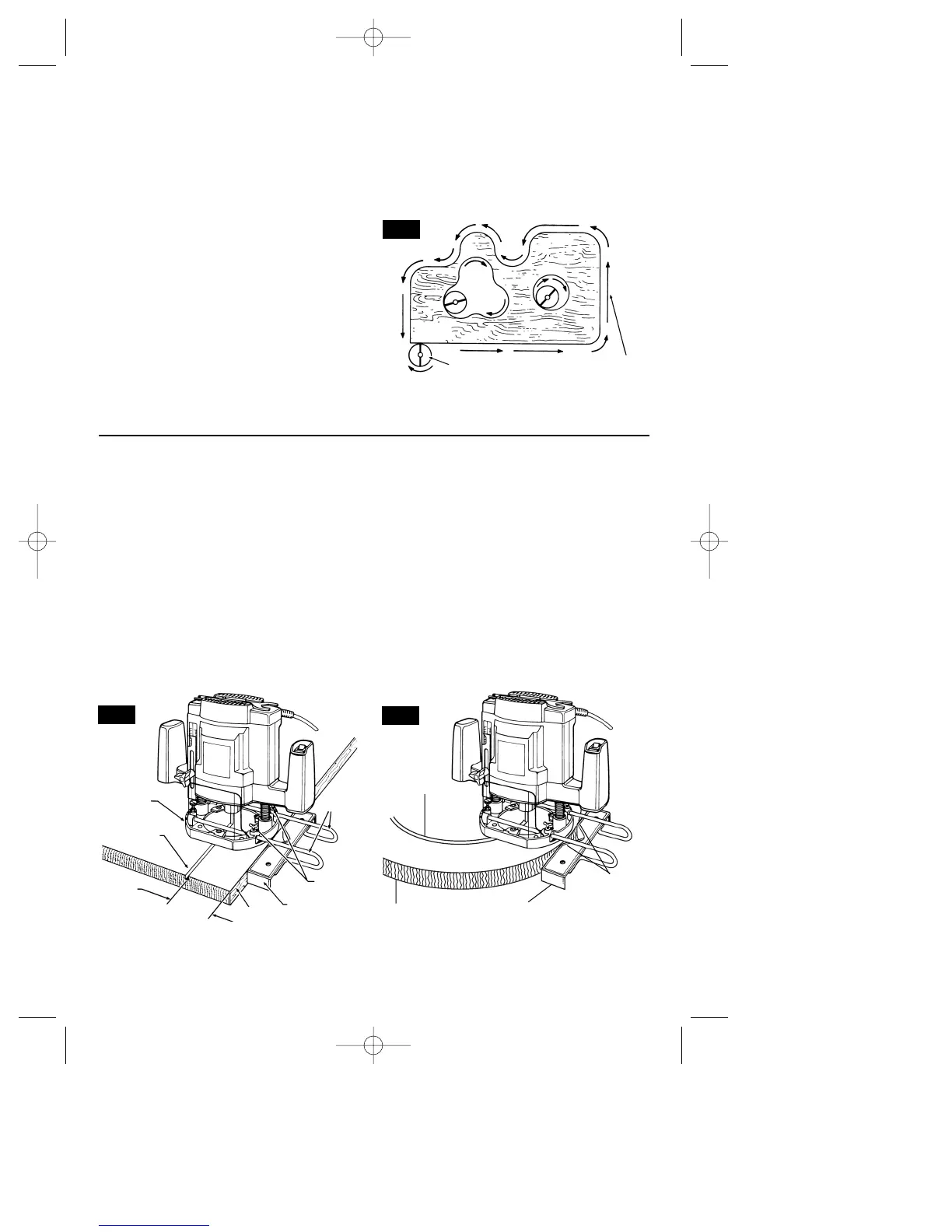

STRAIGHT AND CIRCULAR EDGE GUIDE

(Not included, available as accessory)

Use this handy accessory for ease and

accuracy in making curved and straight cuts.

ATTACHING GUIDE

Insert edge guide rods through holes in base,

slide edge guide to desired width as shown in

(Fig. 5), and secure in place with the two wing

screws provided.

One method of locating the guide is to mark

the center of groove to be cut, set the router

flat on the work with the bit just touching and

aligned over the center of groove. Bring the

guide to the edge of the work, and securely

tighten screws. Whenever in doubt about

dimensions, make a trial cut on scrap

material. For guiding along a circular edge,

the notch in the center of the edge guide will

contact the material at the two points shown

(Fig. 6).

FIG. 5

FIG. 6

DESIRED

WIDTH

CUT

BASE

EDGE GUIDE

WORK

WING

SCREWS

EDGE

GUIDE

RODS

CUT

WORK

EDGE GUIDE

POINTS OF

CONTACT

Loading...

Loading...