the “OFF” position. Preventative maintenance is the easiest and least expensive type of maintenance.

Use original or equivalent to the original parts and components for the aerial platform.

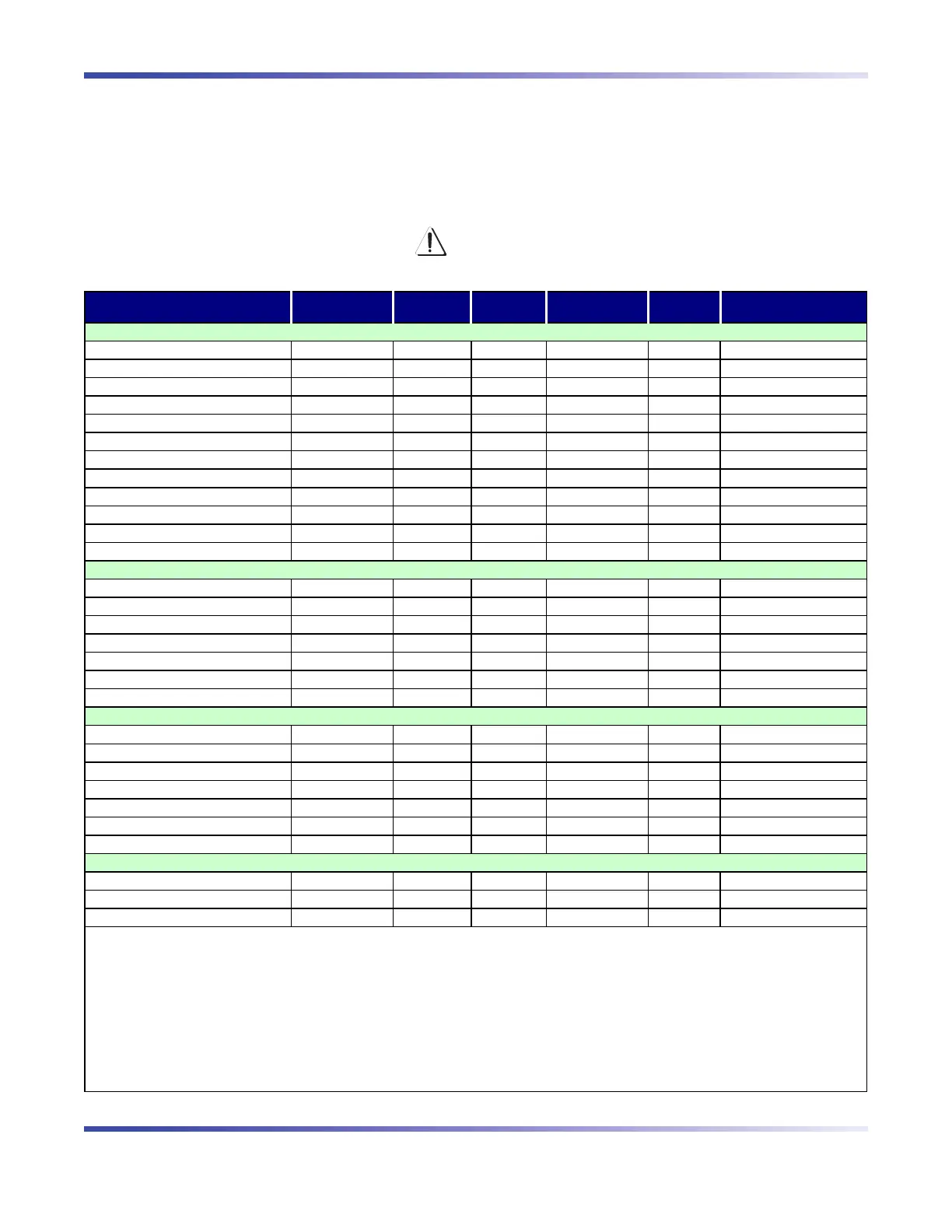

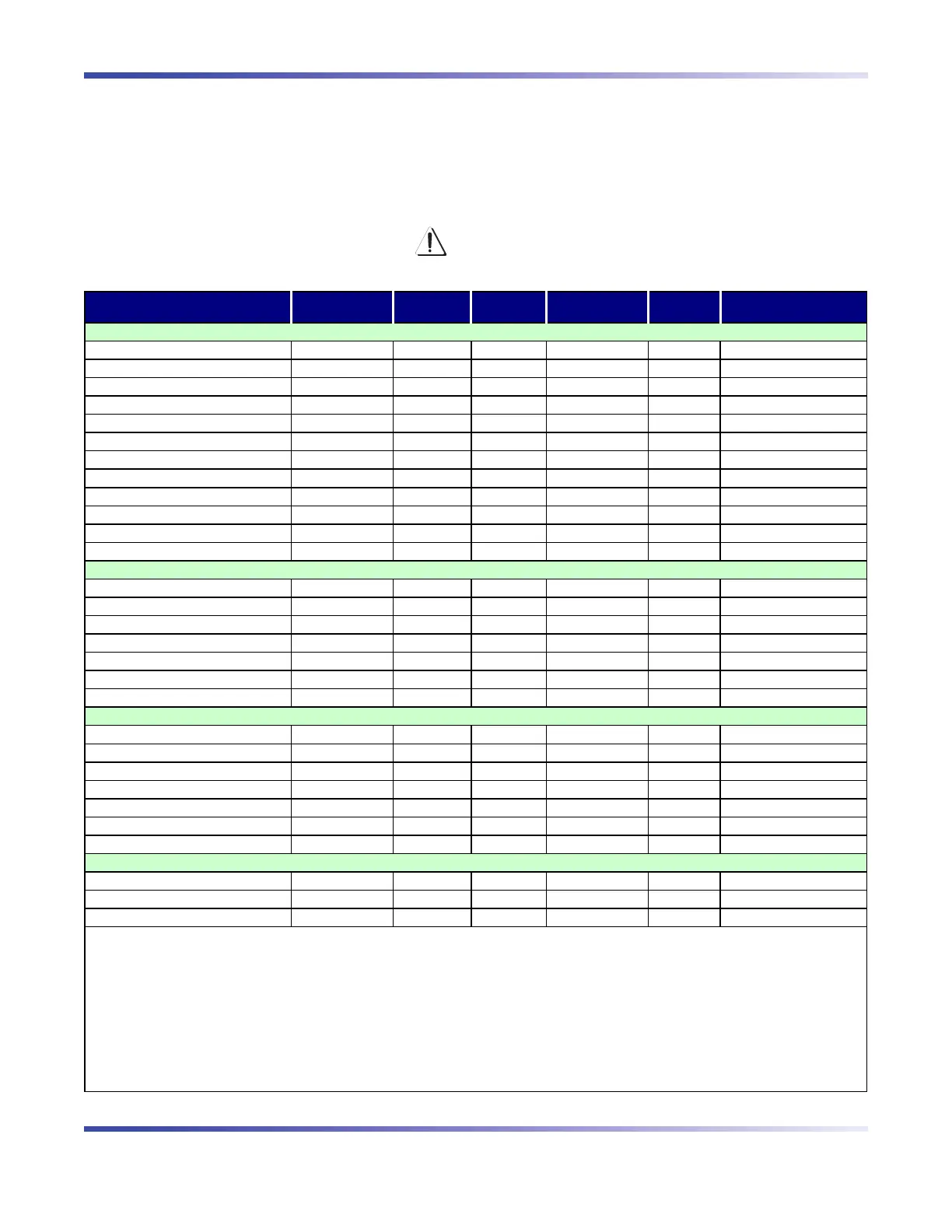

Daily Monthly 3 Months 6 Months 12 Months*

Structural damage/welds A A A

Parking brake B &E B &E B & E

Tires/wheels & fasteners A, B & C A, B & C A, B & C

Guides/rollers & slider pads A, B & I A, B & I A, B & I

Railings & railing lock pins A & C A & C A & C

Entry gates B & C B & C B & C

Bolts and fasteners C C C

Maintenance support B B B

Rust AA A

Wheel bearings & king pins A, B & E A, B & E A, B & E

Axle gear oil** FF

Steering cylinder & tie rod A, B & E A, B & E

Battery fluid level A A A

Control switches A & B A & B A & B

Cords & wiring A A A

Battery terminals A & C A & C A & C

Terminals & plugs C C C

Receptacle A & B A & B A & B

Limit switches B B B

Hydraulic oil level H H H

Hydraulic hoses/fittings A & L A, L & C A, L & C

Lift/lowering speeds GG

Cylinders A & B A & B

Emergency lowering B B B

Lift capacity DD D

Hydraulic oil filter FF

Labels and manual A, J & K A, J & K A, J & K

Lanyard attachments A & C A & C A & C

Check for applicable service bulletins AA

60280AE-PM

Weekly

Mechanical

Electrical

Hydraulic

C

A & B

Notes

Miscellaneous

A.Visually inspect.

B. Check operation.

C. Check tightness.

D. Check relief valve setting. Refer to serial number nameplate.

E. Lubricate.

F.Replace.

G. Refer to Table 2-1a and Table 2-1b, “Specifications and

Features.”

H. Check oil level.

I.Ensure there is no metal to metal contact with slider, slider side or running

surface. Check for free movement of surface. Also check for free

movement of the slider pin

J. Replace if missing or illegible.

K. Proper manual must be in box.

L. Check for Leaks.

* Record inspection date and signature.

** Gear Oil Requirements: Axle: ESSO GX 85W-140

Center Drive: ESSO GX 85W-140

Loading...

Loading...