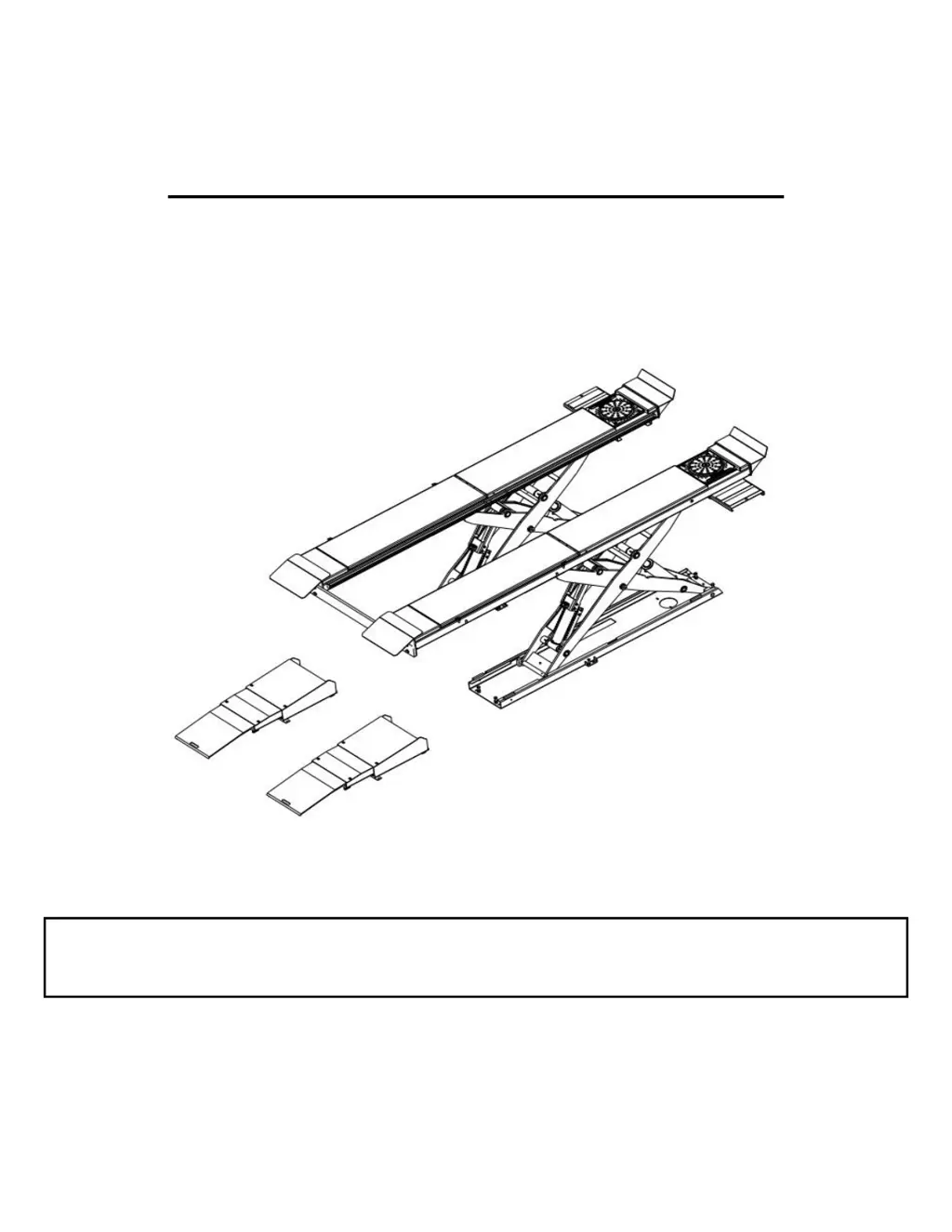

Why won't the motor run on my Snap-on Equipment Scissor Lifts?

- MMegan WillisAug 3, 2025

If the motor of your Snap-on Equipment Scissor Lift isn't running, several factors could be at play. It might be due to a bad fuse or contactor, in which case you should replace them. Another possibility is incorrect voltage reaching the motor, so ensure the proper voltage is supplied. Incorrect wiring could also be the culprit, so it's advisable to have a certified electrician inspect it. The motor switch itself might be malfunctioning and need replacement, or, in the worst-case scenario, the motor might be burned out and require replacement.