32

4-16

4-17

1

2

3

4

5

4-17b

4-18

Layout

4.3 Main shaft lock

Fig. 4-16 Pedal of main shaft lock

The main shaft is locked when the pedal is depressed.

This facilitates tightening or untightening of the

clamping nut and retains the wheel in the correction

position for correct ! tting of the balance weights.

Note:

This lock is designed only to facilitate orientation

of the wheel and must not be used for braking the

main shaft.

Note:

On wheel balancers equipped with the quick–acting

Power Clamp system: The pedal also controls

the Power Clamp, for clamping the wheel on the

balancer.

— Lift the pedal so as to clamp or unclamp the wheel.

— Depress the pedal to actuate the main shaft lock,

thus locating the main shaft.

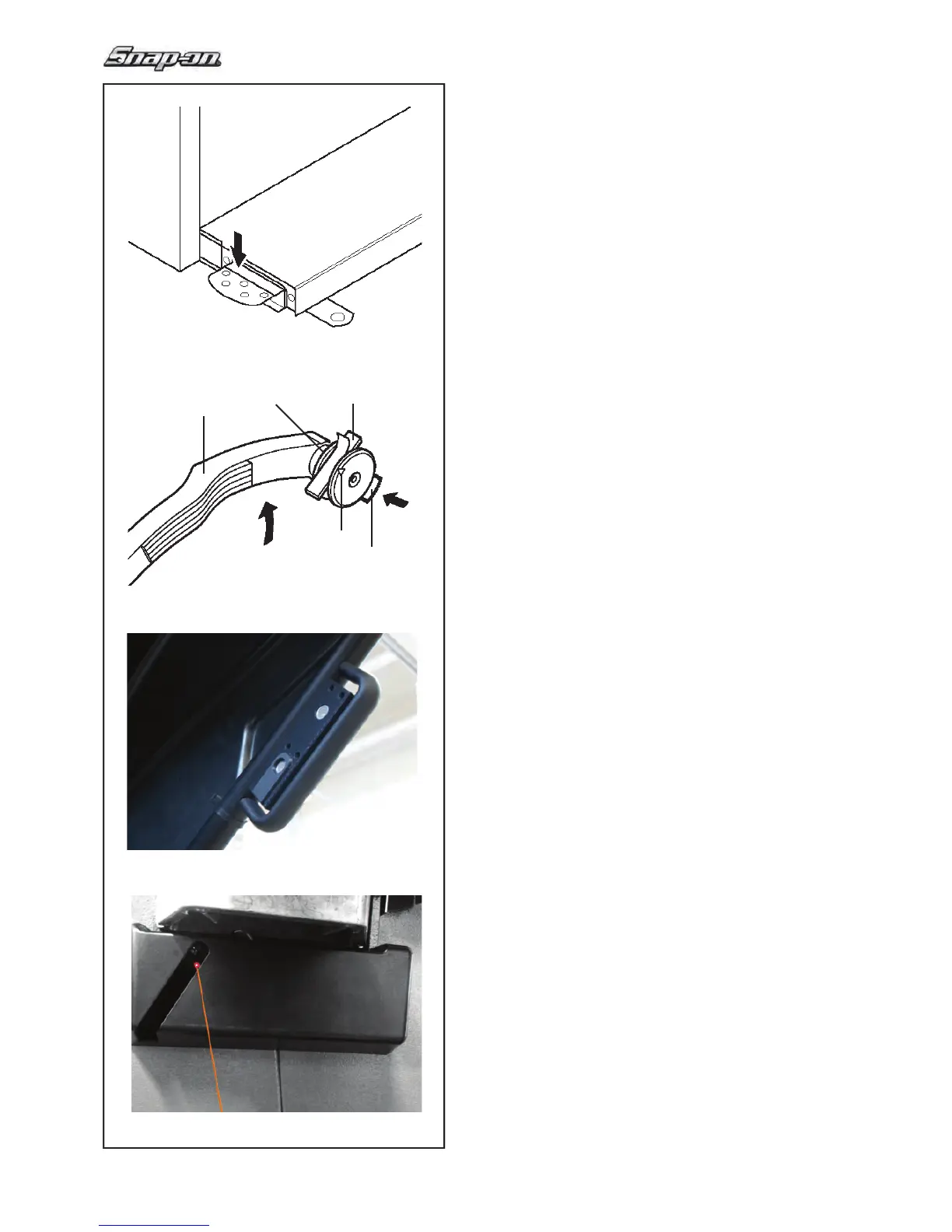

4.4 Gauge arms

Fig. 4-17 Gauge arm for distance and rim diameter

1 Ga

uge arm, can be extended and hinged upwards

2 Weight holder to locate the adhesive weight both

for identi! cation of subsequent ! tting position and

for actual ! tting of the balance weight

3 Adhesive weight held in weight holder

4 Gauge head to identify rim dimensions on a

variety of rim pro! les

5 Spring-suspended applicator.

4.5 Ultrasonic detector

On the outer side of the rim the machine has an

ultrasound detector for the wheel width (outside of

rim) (Fig. 4-17b).

The sonar has a tolerance of +/- 0.5’’.

Such error does not jeopardise the accuracy of the

balancing procedure

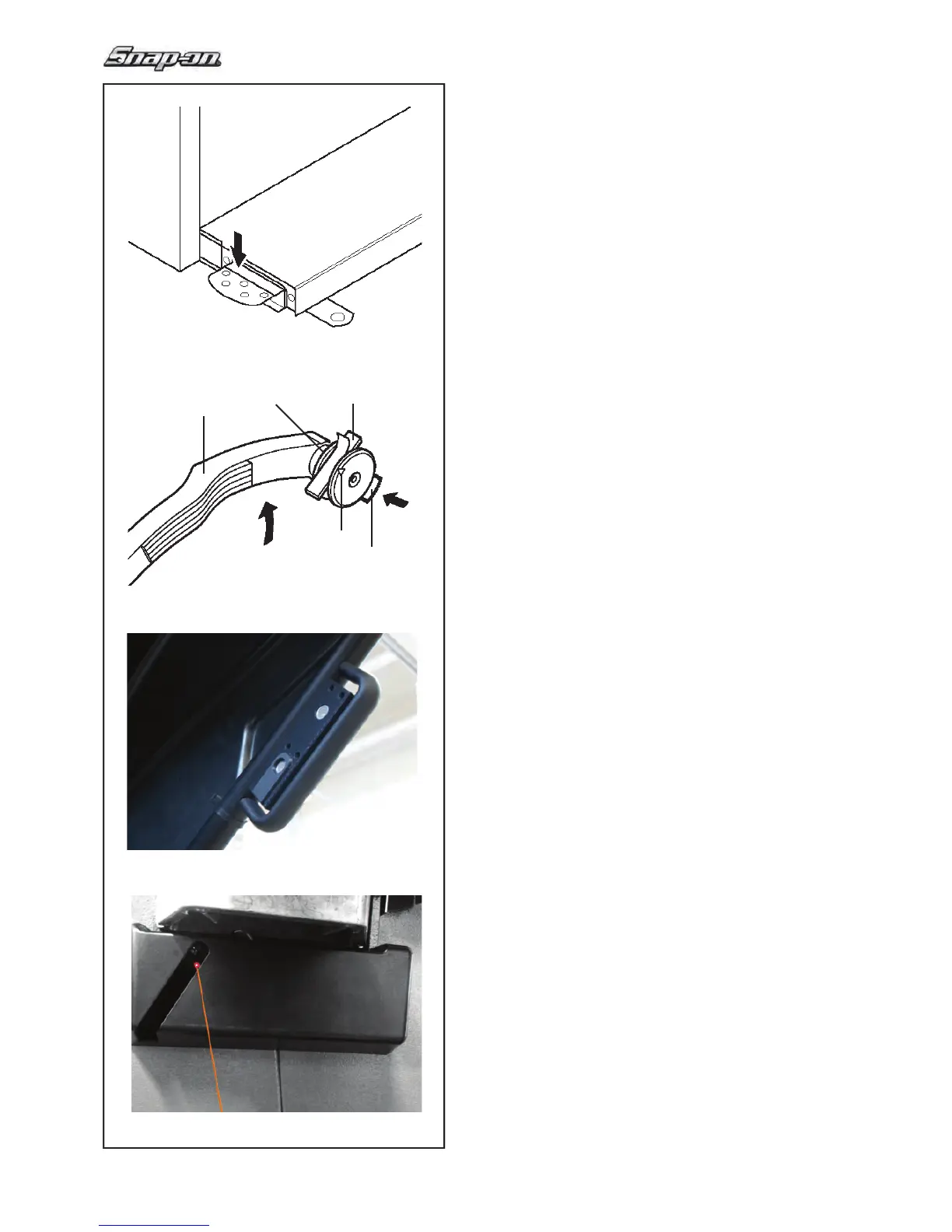

4.6 Laser Pointer

Figura 4-18

The

machine uses

the Laser Pointer to indicate the

precise point for ! tting the adhesive weights on the

rim (F 5.8).

Note:

If the machine is set in Gauge arm mode as default, the

Laser Pointer mode can be activated by calling service.

Loading...

Loading...