directly on the meter scale in terms of

megohms.

To make the instrument ready for

insulation resistance

tests proceed as

follows:

1.

Set

the selector switch on position Mxl (See chart

below).

2.

Switch

the meter to the 5 ma. range.

3.

Adjust

the voltage control so that the meter

reads

infinity

)

which is

the null position.

4. Connect the test

leads, with the rubber

protections

over the dips, across the condenser under

examina-

tion and read

the meter deflection, which

is given

directly in megohms.

On

low capacity units

like

mica condensers,

the

reading

can be

taken almost

immediately; on higher capacity units it

will

be

necessary to wait until the condenser becomes

charged

and

the meter deflection

comes to rest;

this

may take about I

minute

for a I mfd. capaci-

tor. The difference in time between

low and high

capacity condensers

is due to the difference in

the

charging

rate. The high capacity

condenser

takes longer to charge.

S«lecfor

Insulation Resistance Multiply

Setting

in Meqohms

Scale by

MX

1 3 to 100

megohms 1

MX 10

30 to 1000 megohms

10

MX 100

300 to 10000

megohms 100

If the meter

deflection is greater

than 100 megohms

on range

MX I, set selector

switch on position MX

10

and, if it is still greater

than 100 on this

range, set the

selector switch

on range MX

100. the next highest setting.

SATISFACTORY —

Insulation values greater

than 50

megohms.

(See note below.]

LEAKY

—

Insulation values

less than 50 megohms.

(Re-

place condenser)

SHORTED OR

LESS THAN

3

MEGOHMS

—

Meter

deflection reads zero.

(Replace condenser.)

OPEN

—

No variation

in the meter deflection. (Replace

condenser.)

The

leakage check

on paper,

mica,

trimmer,

and

all

solid dielectric

condensers is made

in the manner de-

scribed.

NOTE

—

The insulation resistance

of 50 megohms will

be found satisfactory

for most applications

with the

exception

of coupling condensers.

In the case of

coupling condensers

the insulation resistance

should

be above

200 megohms.

Values of resistors greater than 3

megohms

can be

tested on

this range. The checks are made in the man-

ner described above.

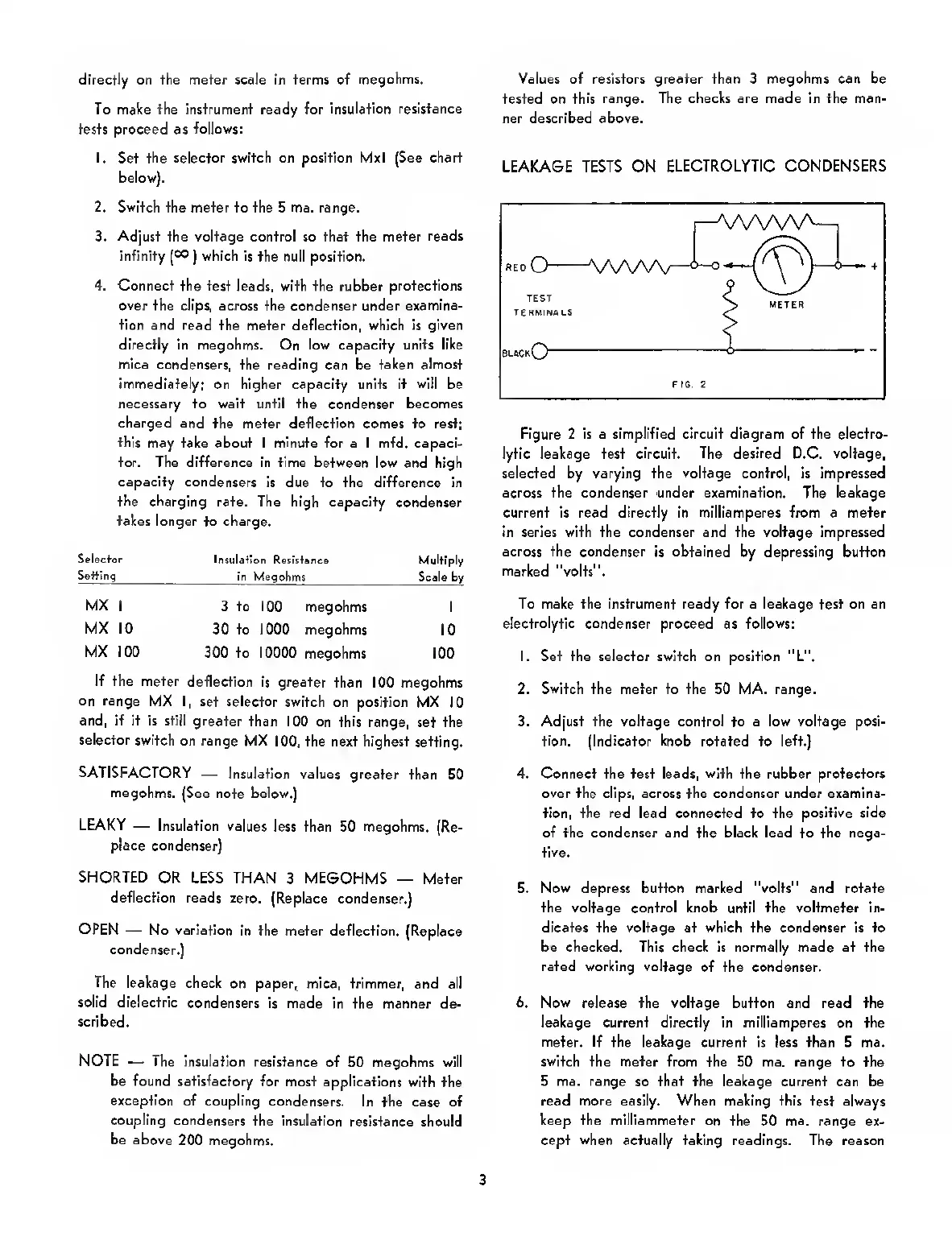

LEAKAGE TESTS ON

ELECTROLYTIC CONDENSERS

Figure 2 is a simplified circuit diagram of the electro-

lytic leakage test

circuit. The desired

D.C.

voltage,

selected by varying the voltage control, is impressed

across the condenser under examination. The leakage

current is read directly in milllamperes from a meter

in series with the condenser and the voltage impressed

across the condenser is obtained

by depressing button

marked

"volts".

To make the instrument ready for a leakage test on an

electrolytic

condenser proceed as

follows:

1. Set the selector switch on position ”L",

2. Switch the meter to the 50 MA. range.

3. Adjust the voltage control

to

a low voltage posi-

tion. (Indicator knob

rotated to

left.)

4. Connect the test leads, with the rubber

protectors

over the clips, across the condenser under examina-

tion, the red lead connected to the

positive side

of the condenser and the black lead

to

the nega-

tive.

5. Now depress button marked "volts" and rotate

the voltage control knob

until

the voltmeter in-

dicates the voltage at

which

the condenser is to

be checked. This check is normally made at the

rated working voltage

of the condenser.

6. Now release the voltage button and read the

leakage current directly

in

milliamperes

on

the

meter. If

the leakage current is less than 5 ma.

switch the meter from the 50 ma. range to the

5 ma. range

so

that

the

leakage

current can be

read more easily. When making this test always

keep the milliammeter on the

50

ma.

range ex-

cept

when

actually taking readings. The reason

3

Loading...

Loading...