for this is that it is impossible to damage the

meter when

it is adjusted for the high current

range because the instrument

has

been designed

to prevent

excess current

from

damaging the meter

element.

SATISFACTORY

—

The leakage current should come

down

to 5

ma.

or less. The time required for

the

current to be reduced to this value depends upon

the length of time the capacitor

has been out of

service.

HIGH LEAKAGE

—

A condenser in which the leakage

current does not come down

to 5 ma.

after 20

to

30 minutes of

application of rated D.C. voltage

should be considered defective and replaced.

SHORTED

—

Appreciable flickering in the leakage cur>

rent. (Replace

condenser.)

Tests of electrolytic

condensers that have been out

of

service

for long periods of time may be speeded

up

by continued adjustment

of the

voltage

so that it Is kept

at

the initial setting of the test voltage.

For

example as the leakage current is reduced the

D.C. test voltage will have

a tendency to

Increase

re-

sulting in an increase in the leakage current. Reducing

the test voltage

to the rated value will reduce the leak-

age current proportional to the reduction

in

voltage.

It sometimes happens when

the condenser has been

out of service

15 to 20 months that it Is more convenient

to start with a D.C. voltage less than rating not

sufficient

to give 40

to

50 milliamperes

and to increase the voltage

as the

current is decreased up to rated voltages. When

rated voltage is reached

proceed as described above.

CAPACITY

OF PAPER, MICA, TRIMMER,

ELECTROLYTIC AND

AIR CONDENSERS

POWER FACTOR

OF ELECTROLYTICS

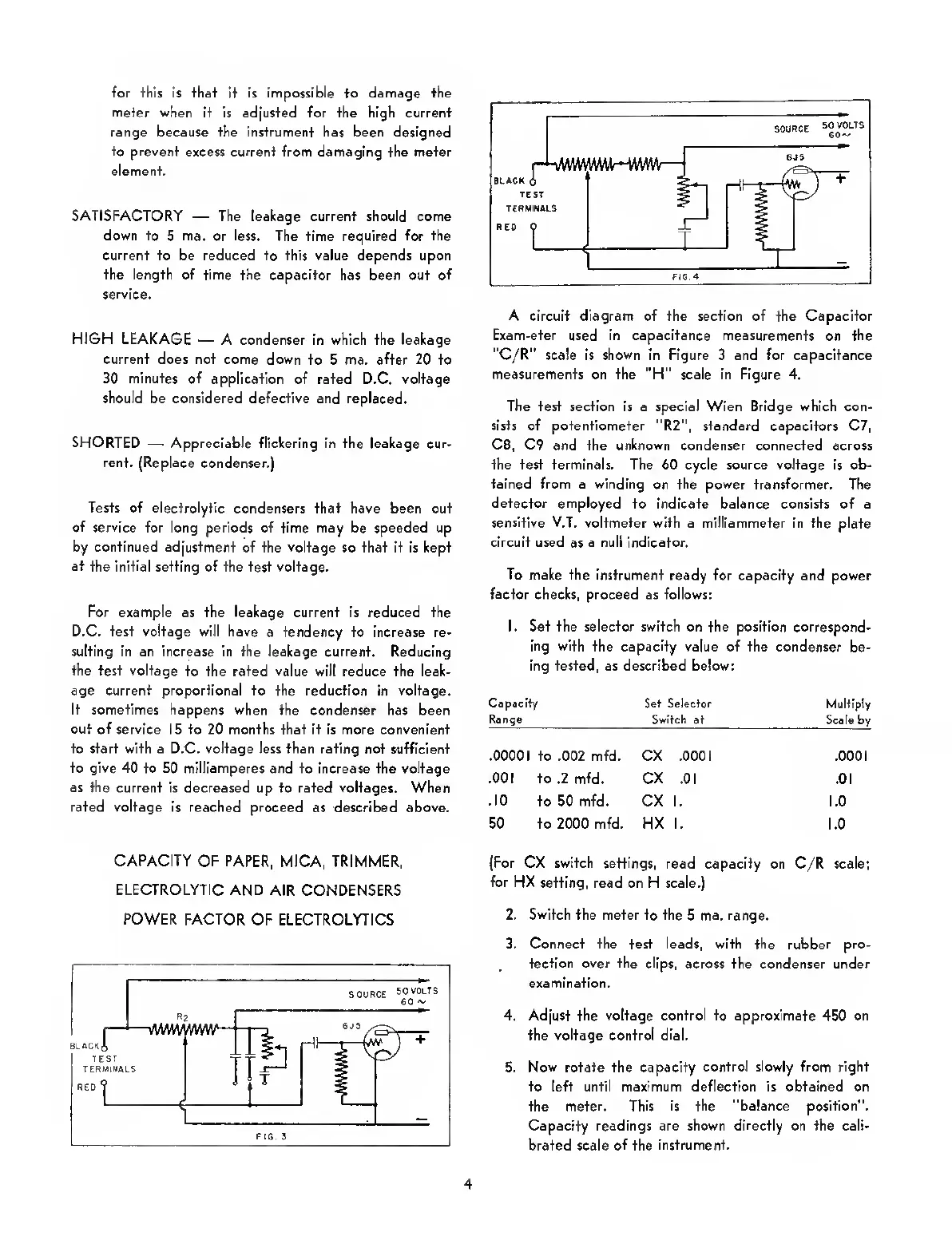

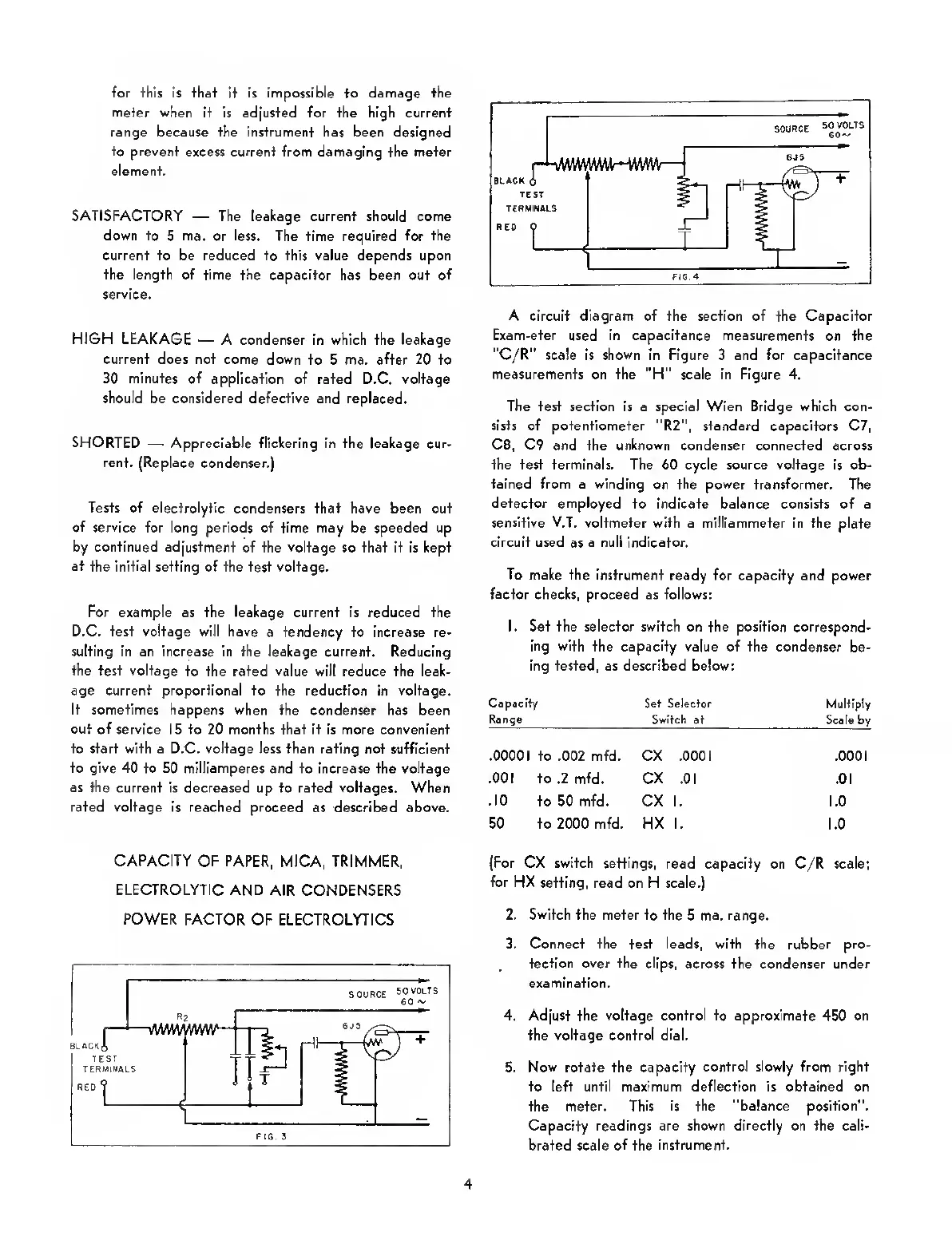

A circuit diagram of the section of the Capacitor

Exam-eter used in capacitance measurements

on

the

"C/R" scale is

shown

in Figure 3 and for capacitance

measurements on the "H" scale in Figure 4.

The test section Is a special Wien Bridge which con-

sists of potentiometer "R2", standard capacitors C7,

C8,

C9 and the

unknown

condenser connected across

the test terminals. The 60 cycle source voltage is ob-

tained from a winding

on

the power transformer.

The

detector

employed to indicate balance consists of a

sensitive V.T.

voltmeter with a milliammeter in the plate

circuit used

as

a null Indicator.

To make the

instrument ready for capacity and power

factor checks, proceed as follows:

I. Set the selector switch on the position correspond-

ing

with

the capacity value of the condenser

be-

ing tested, as described below:

Capacity Set Selector

Multiply

Switch

4t Sc^le by

.00001 to .002 mtd. CX .000

1

.0001

.001 to .2 mfd. CX

.01 .01

.10

to 50 mfd. CX 1. 1.0

50 to 2000 mfd. HX 1.

1.0

(For CX switch settings,

read capacity on C/R scale;

for HX

setting, read on H scale.)

2.

Switch

the meter to the

5

ma. range.

3. Connect the test leads, with the rubber pro-

tection over the clips,

across the condenser under

examination.

4. Adjust the voltage control to approximate 450 on

the voltage control

dial.

5.

Now

rotate the capacity

control slowly from right

to left until maximum deflection Is obtained on

the meter.

This Is the "balance position".

Capacity readings are shown directly on the cali-

brated scale

of

the

Instrument.

4

Loading...

Loading...