a

C.

2. Insert the test leads, with the rubber

protectors

over the clips,

into the tip jacks marked "D.C.

volts". The red plug should be connected

to the

red jack and the

black plug to black jack

to ob-

tain the correct polarity.

3.

Switch the meter

to the 5 milliampere range.

4. Adjust the voltage control

so that the

meter reads

"O" on scale V.D.C. This is

the

null point.

5. Now

connect the test leads across the voltage to

be measured

and read the

meter detlection which

is

given directly in volts.

A.C.

VACUUM TUBE VOLTMETER

The A.C. V.T. voltmeter is used as an output indicator

for circuit alignment.

The

voltmeter has an input re-

sistance

of 10 megohms and has a range of 10 to 50

volts

D.C. To make the instrument ready for voltage

checks,

proceed as follows;

1. Set the selector switch on position MX 100.

2. Insert

the test

leads, with

the rubber protectors

over the clips, into the tip jacks marked "A.C.

volts".

3.

Switch

the meter to the 5 ma. range.

4. Adjust

the

voltage

control so that the meter reads

5 ma. This is the null point.

5. Now

connect the test leads across the voltage to

be measured and read

the

meter

deflection which

Is given

in milliamperes.

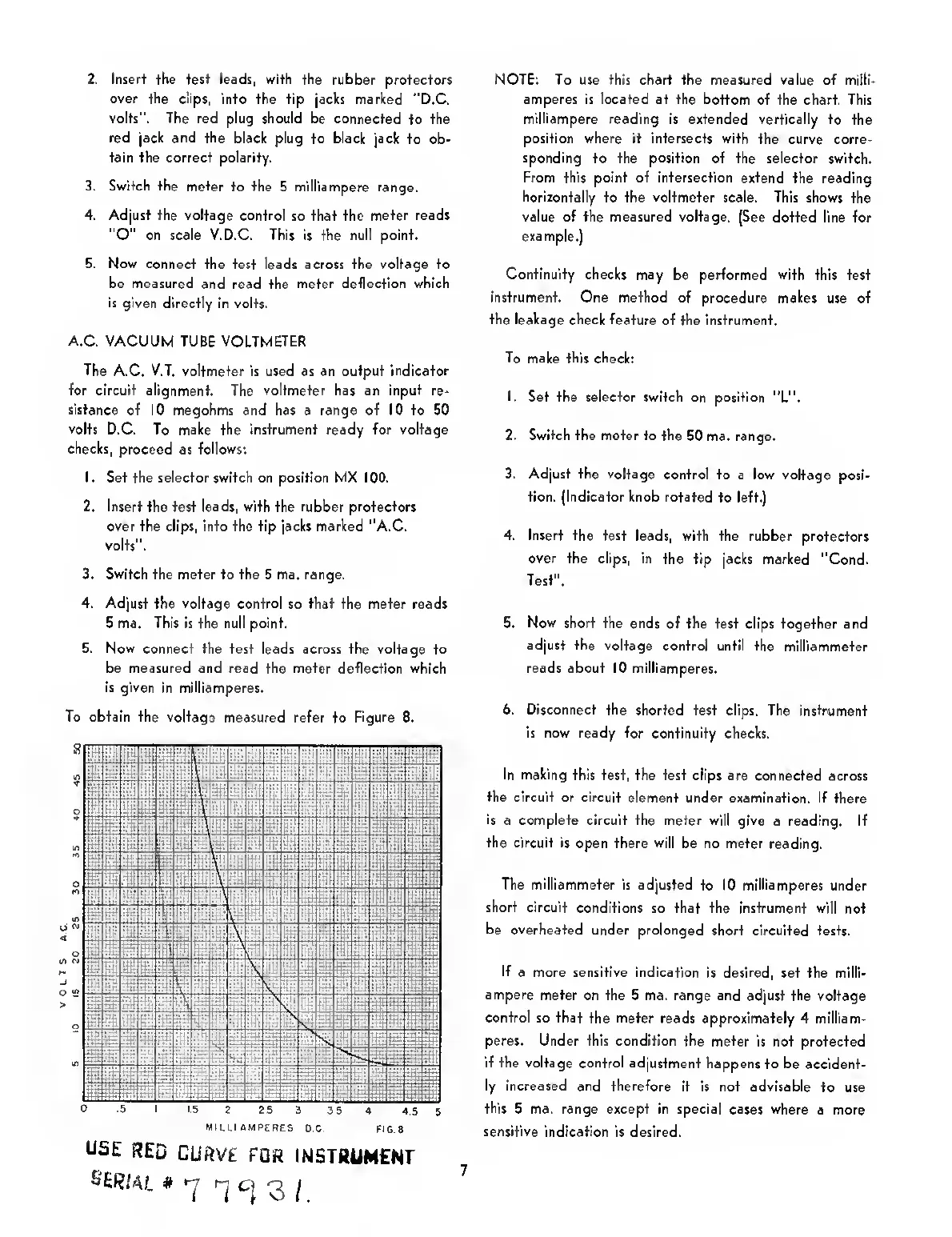

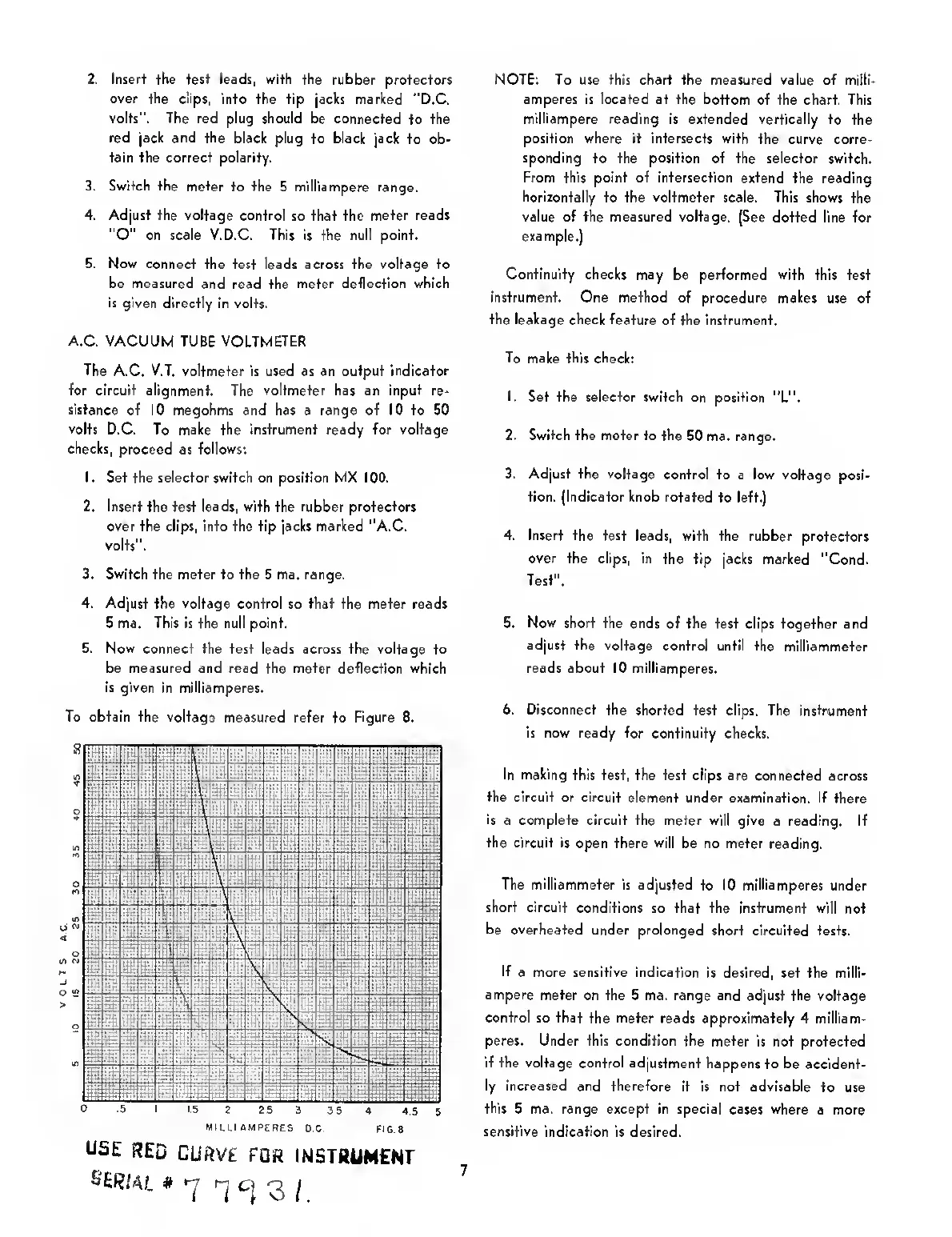

To obtain the voltage

measured refer to Figure 8.

MILL! AMPERES

O.C.

FIG

8

USE

RED

CURVE

FOR

INSTRUMENF

NOTE: To use this chart the measured value of

mill!-

amperes is located at the bottom

of the chart. This

milliampere

reading is extended vertically to the

position where it intersects with

the curve corre-

sponding

to the

position

of the selector switch.

From this point of intersection extend

the reading

horizontally

to the

voltmeter

scale. This shows

the

value of the measured voltage. (See dotted

line for

example.]

Continuity checks

may be performed

with

this test

instrument. One method of procedure makes

use of

the leakage check feature

of the instrument.

To

make this check:

1.

Set the selector switch on

position "L".

2. Switch the meter to the

50 ma. range.

3. Adjust the voltage

control to

a

low voltage

posi-

tion. (Indicator knob rotated

to left.}

4. Insert the

test leads, with the rubber protectors

over the clips, in

the tip jacks marked "Cond.

Test".

5.

Now

short the ends

of the test clips together and

adjust the voltage

control until the

mlltiammeter

reads about 10 milliamperes.

6. Disconnect the

shorted test clips. The instrument

is now ready for

continuity checks.

In making

this test, the test clips

are connected across

the circuit or circuit

element under examination.

If there

is a complete circuit the meter will give

a reading. If

the circuit is

open there

will

be no meter

reading.

The milliammoter

is adjusted

to 10

milliamperes

under

short circuit

conditions so that the instrument will

not

be overheated

under prolonged

short circuited tests.

If

a more sensitive indication

is

desired,

set the milli-

ampere

meter on the 5 ma. range and adjust the

voltage

control so that

the

meter

reads approximately 4 milliam-

peres. Under this condition the meter

Is not protected

If the voltage control adjustment

happens to

be accident-

ly Increased and therefore

It Is not advisable

to use

this

5 ma. range except in special cases where

a more

sensitive

Indication Is desired.

7

Loading...

Loading...