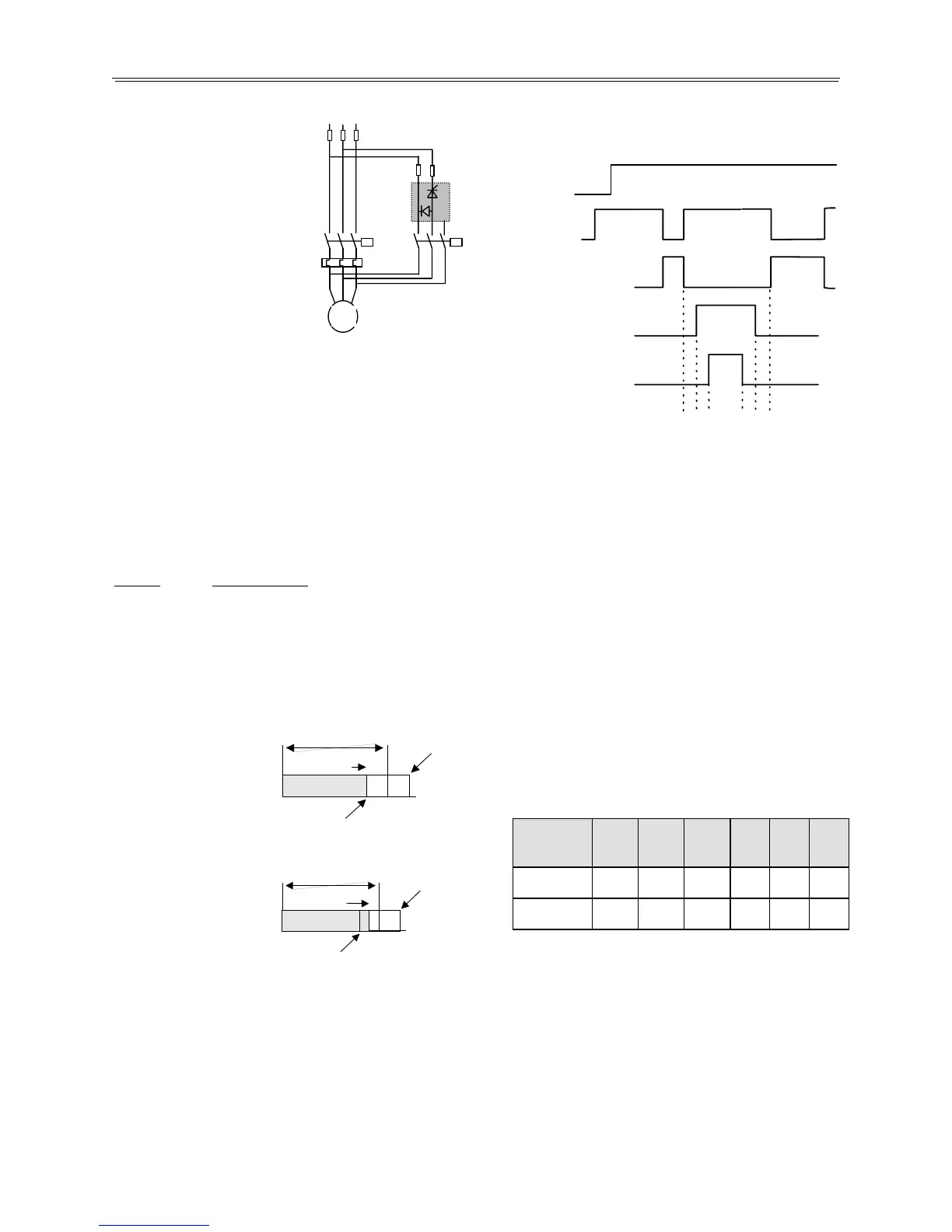

Mode of Operation

Stop signal opens motor contactor

C

1

that in turn initiates the closing

of brake contacts C

2

.

The Thyristor is switched on and

fire (to inject DC current to the

motor) after time delay, to induce

the braking current.

The torque, which is a function

of the DC current, can be

controlled

by the firing angle of the

Thyristor.

Note: there is a time delay

between opening of one

contactor and closing the other

one to reduce the EMF. The time

delay correlate to the size of the

motor.

Braking Time

Braking time depends on the inertia, friction of the load,

speed, and braking current. The required braking time is

best established by practical experience.

The Solbrake / SMB offers two operating modes,

Automatic and Manual. Selection between the modes is

one by an internal dip switch. d

Dip sw.

Operation Mode

On Manual

O

ff Automatic

It is recommended to use the Automatic mode (factory

default setting) to reduce the braking time and minimize

motor heating.

Automatic operation

DC injection duration is

automatically controlled

by the Solbrake / SMB.

Injection ceases when

Motor has come to a

complete stop.

Manual operation

DC injection duration is

according to the Braking

Time setting on the front

panel.

Notes:

1. Motor heating during braking is similar to heating

during Direct On Line starting. Therefore, always

adjust for the shortest DC injection time duration.

2. In general, for improved braking process to be in effect,

it is recommended to apply some minimal inertia on the

motor shaft.

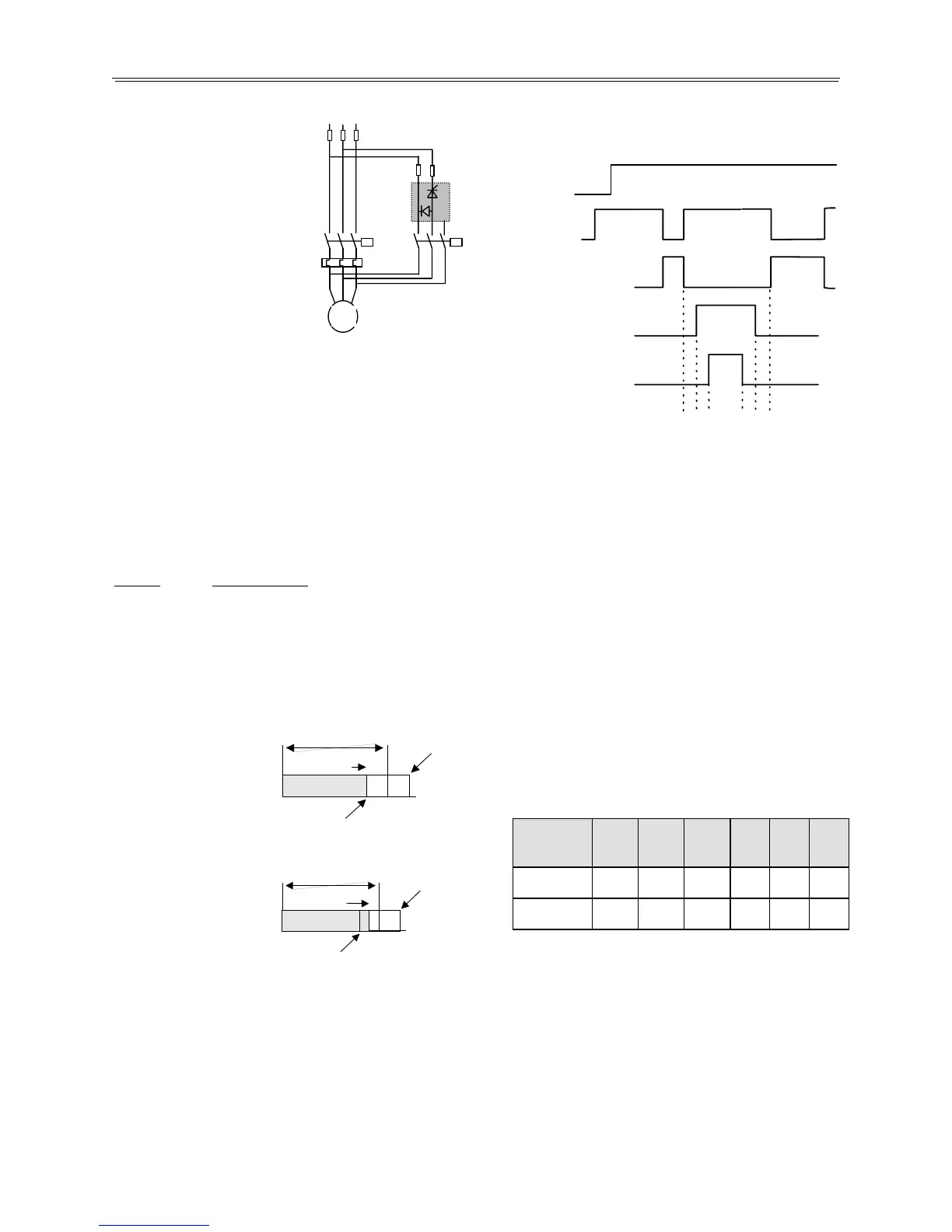

The Solbrake / SMB incorporates the following built-in

time delays:

t

1

DC Injection

Brake Contactor

Motor Contactor

1 - 2 Open

t

2

t

3

t

4

t

5

1 - 2 Closed

Power ON

Motor

Running

Braking

Process

Start Sto

M

Where:

t

1

- Time delay between opening of motor's contactor C

1

and closing of brake contactor C

2,

allowing motor's

back EMF to diminish (see table below).

t

2

- Time delay of 0.05 sec between closing of brake

contactor C

2

and initiation of DC current, to ensure

that brake contactor does not switch DC current,

enabling the use of regular AC contactor.

t

3

- In Auto Mode – Enabling of DC current injection.

In Manual Mode - time of DC current injection.

Range: 1-10 sec.

t

4

- Time delay between end of DC current injection and

opening of brake contactor C

2

to ensure that the

contactor does not switch DC current, enabling the

use of regular AC contactor (see table below).

t

5

- Time delay of 0.2 sec. between opening of brake

contactor C

2

and enabling motor's restart.

Approximate Time Delays (sec).

Sec.

10

1

DC Injection

Motor Stopped

Braking contactor Closed

Restart Enable

Solbrake

/ SMB

8

17

58

105

210

390

t

1

0.2

0.3

0.6

1.1

1.7

2.5

t

4

0.2

0.2

0.3

0.8

1.2

1.9

Sec.

10

1

DC

Injection

Motor Stopped

Braking contactor

Restart Enable

Torque at standstill

When required to maintain the DC braking current after the

motor has come to a complete stop, set Auto/Man Dip

Switch to On (Manual operation). Set Braking Time to a

longer time than it takes the motor to come to a complete

stop.

Note - DC Injection after motor has come to a complete

stop may cause excessive heating of both the motor and the

brake.

5

Loading...

Loading...