Soosan

H

draulic Breaker

Soosan Heav

Industries Co.

Ltd

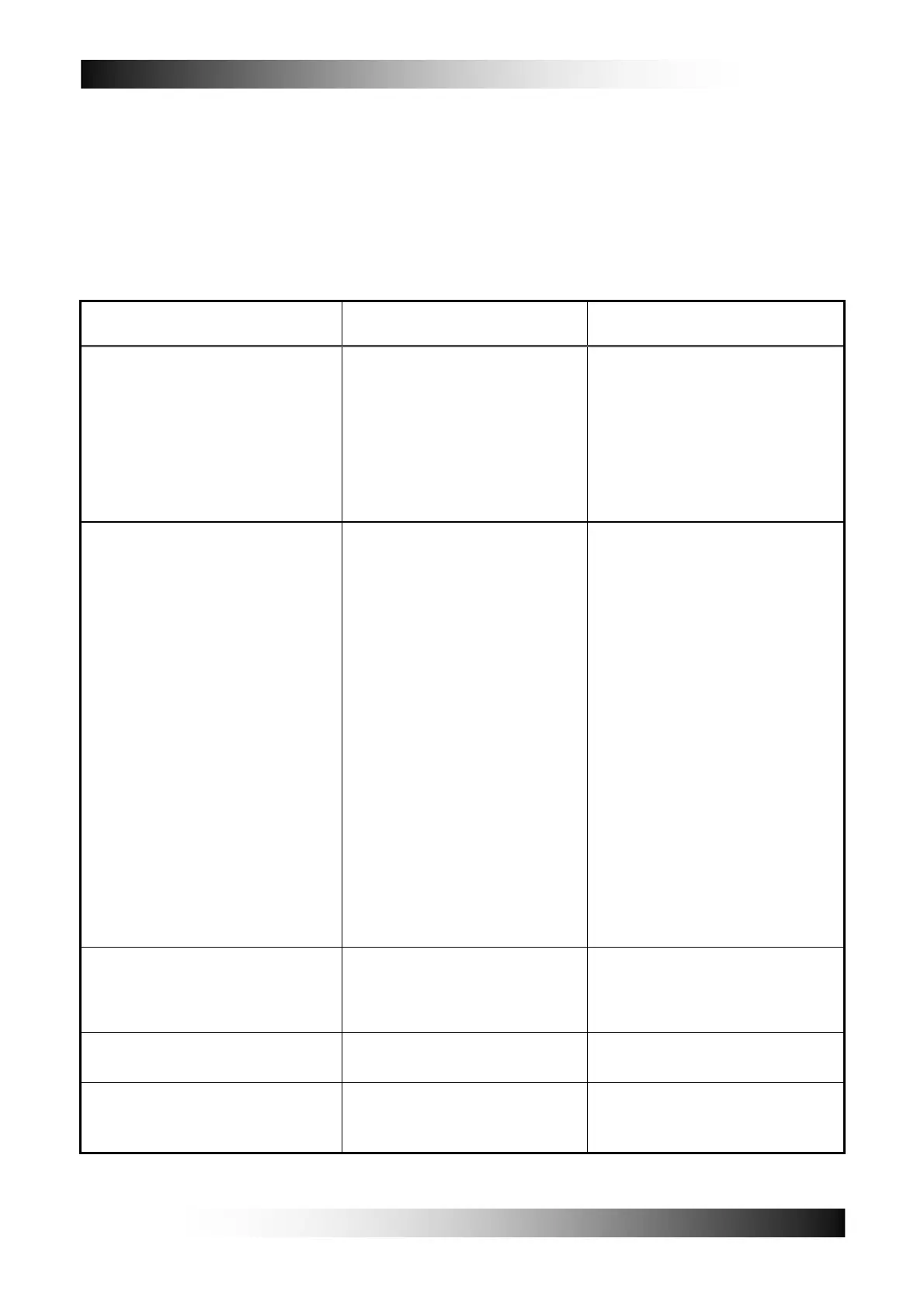

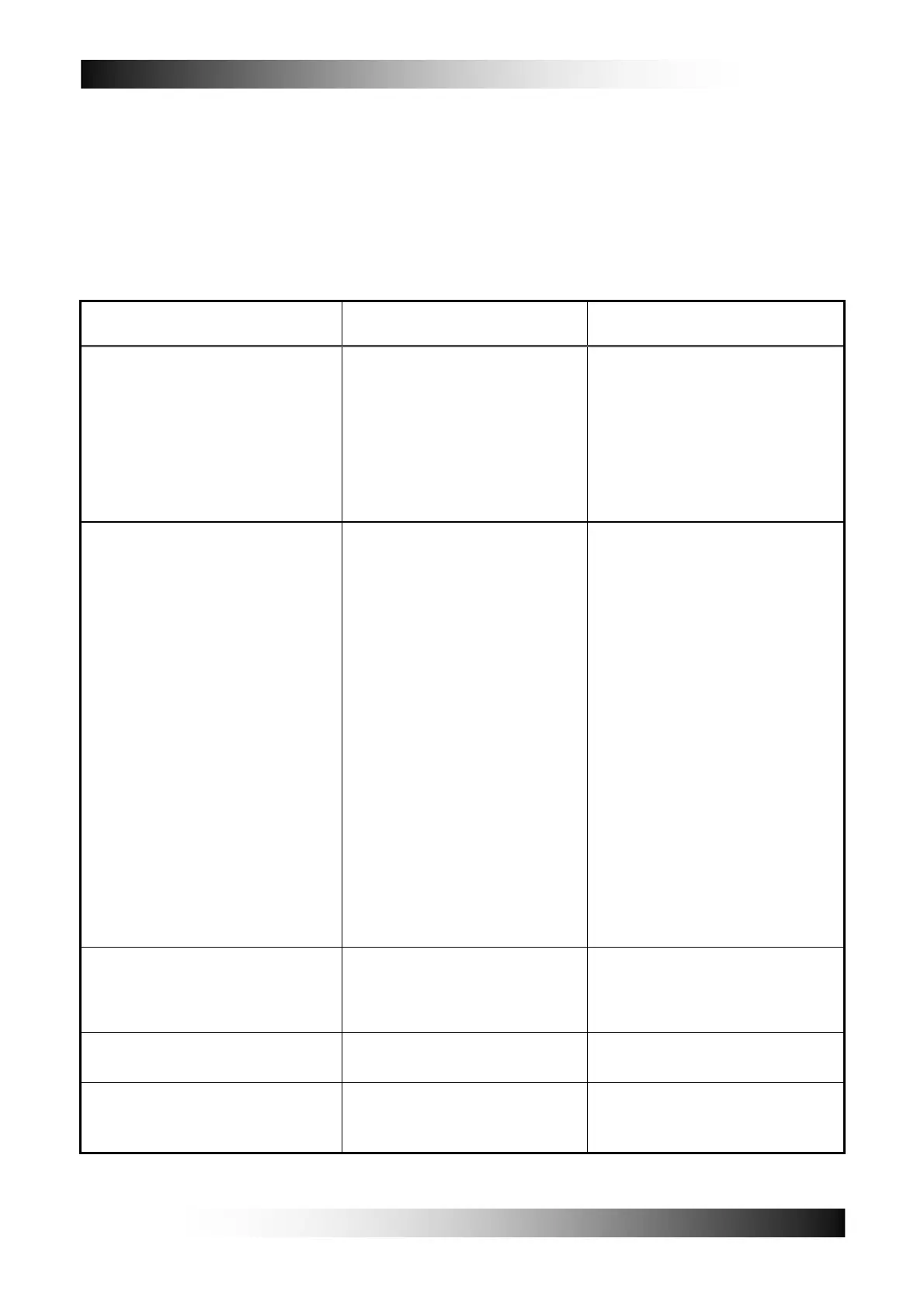

10. Trouble Shooting

The trouble-shooting chart is prepared to help operators find out causes and remedies instantly when

troubles occur. When a trouble is found, have a good grip of the problem and contact our service station.

When diagnosing faults in operation of the breaker, always check that hydraulic power source is supplying

the correct hydraulic flow and pressure to the breaker as listed in the table.

Check the flow with the hydraulic oil temperature at least 176 /80 . An approved test procedure is ℉℃

available form Soosan.

TROUBLE CAUSE REMEDY

1. Breaker fails to hammer

* Sufficient high pressure oil does

not flow to breaker inlet.

* Sufficient high pressure oil flows

to breaker inlet.

* Defective hose or pipes·

* Clogged or damaged piping

* Defective control valve and

related parts

* Insufficient hydraulic oil

* Internal breaker defects

* Check, clean and repair piping

or replace with new one.

* Check and repair valve and its

related parts or replace with

new one.

* Refill oil tank.

* Consult with our service station.

2. Breaker hammers with

hammering force reduced.

* Sufficient high pressure oil does

not flow to breaker inlet.

* Sufficient high pressure oil

flows to breaker inlet.

* Defective hose or pipes

Clogged piping, Oil leakage

* Defective control valve and

related parts

* Deformed pedal

* Deformed control valve

* Stuck control valve

* Insufficient control valve

stroke due to loose screws

* Clogged filter in return line of

base machine tank

* Insufficient hydraulic oil

* Contaminated or deteriorated

hydraulic oil

* Defective pump

* Internal breaker defects

* low N

2

-gas pressure of back

head

* Check, clean and repair piping

or replace with new one.

* Check control valve and related

parts or replace with new one.

* Clean or replace.

* Refill.

* After flushing tank, change oil

entirely.

* Ask service station for base

machine service.

* Consult with our service station.

* Adjust the gas pressure referring

to Chapter 10.

3. Hammering force weakens

suddenly and high pressure

hose vibrates excessively

during operation.

* Defective Back Head Gas

leakage

* Ask our service station for repair.

4. Excessive oil leakage from

Front Head or Rod.

* Worn cylinder seals

* Ask our service station for repair.

5. Piston works but does not

hammer.

* Stuck in rod

* Remove front parts and pull out

rod.

* Repair with a grindstone.

Ask base machine service station to repair defective base machine.※

Loading...

Loading...