5

ENGINE ADJUSTMENTS

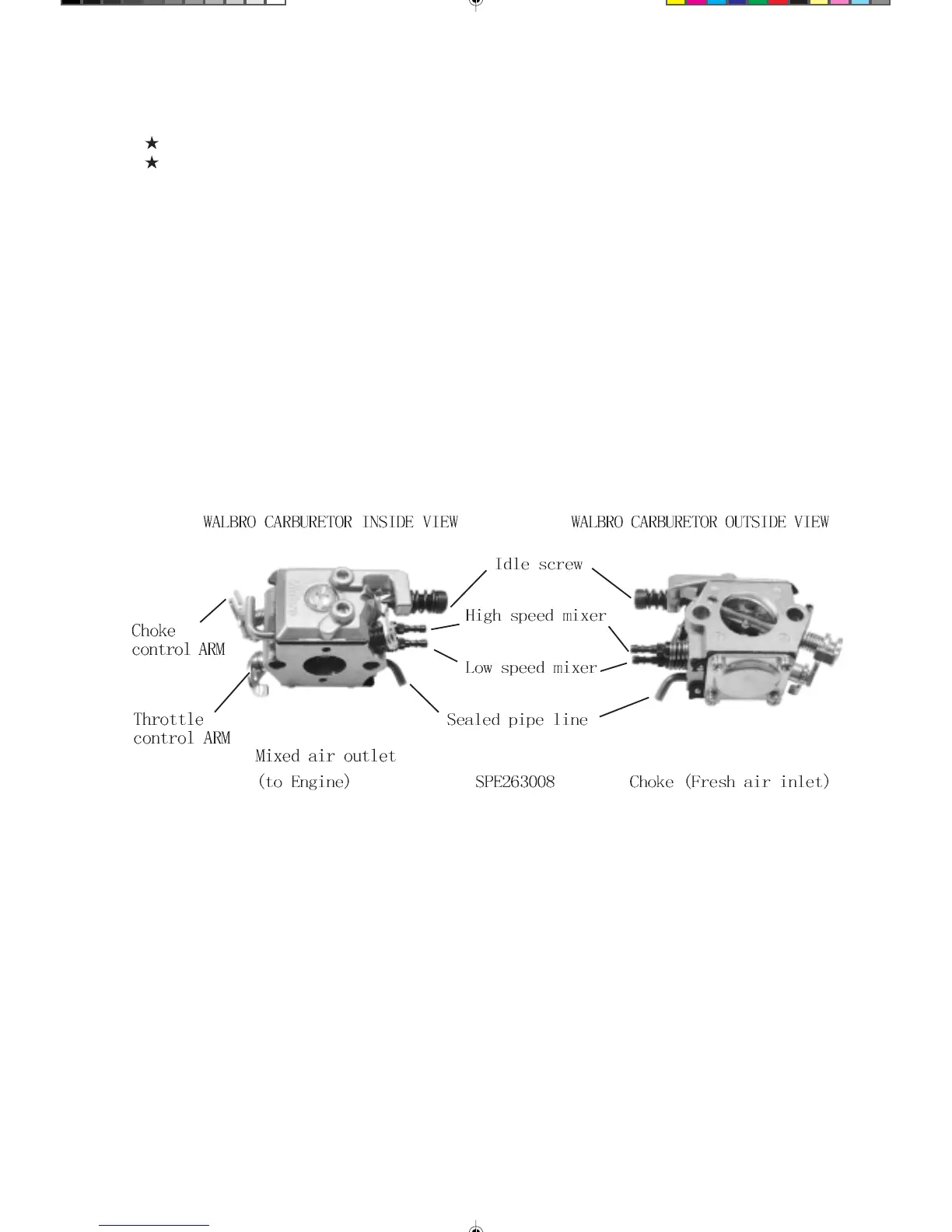

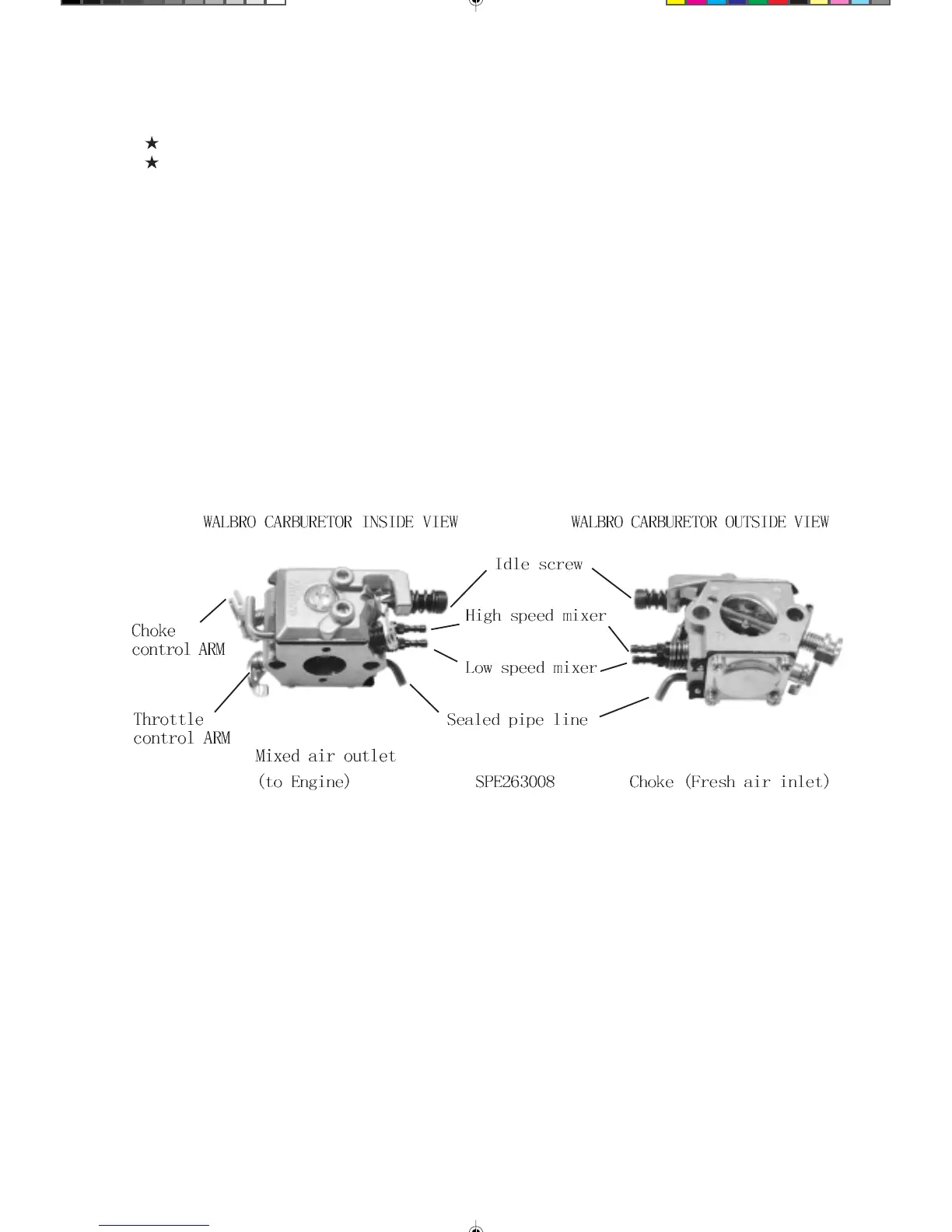

Always make high- and low-speed needle adjustments with the engine shut off.

Also make sure the ignition is OFF. · Adjust the needle marked “H” for high-speed RPM. Adjust the needle

marked “L” for low-speed RPM.

A. Normal high- and low-speed needle settings:

It is not necessary to change the needle settings if the engine runs smoothly. Normally only the “H” needle will

need adjustment from time to time and only by a small amount.

H: Open the needle 2 turns from the closed position (±1/4 of a turn in winter).

L: Open the needle 1-3/8 turns from the closed position (±1/4 of a turn in winter). Only adjust the high- and

low-speed needle within the above range.

B. Idle adjustment:

Note: Do not confuse the idle screw with the low-speed needle “L”. The idle screw physically adjusts how

much the carburetor valve can close. The low-speed needle “L” adjusts the gasoline-to-air mixture when the

engine is running at low RPM. If your engine appears to work correctly except that the low RPM are not as low

as you want them to be, and then adjust the idle screw. If your engine behaves erratically at low RPM, then

adjust the low-speed needle “L”. When adjusting, turn the screw about 1/8 of a turn each time. A dirty plug will

make it difficult to adjust the idle RPM. Follow the recommended procedures if any of the following happens:

Problem:

1. The engine hesitates when accelerated rapidly.

2. The RPM increases at idling.

3. The engine stops when the throttle is moved from high to low.

Solution:

Your low-speed needle “L” is too lean. Open it up about 1/8 of a turn and try again.

Problem:

The idle is not steady.

Solution:

Your low-speed needle “L” valve is too rich. Close it 1/8 of a turn and try again.8

C. High-speed Adjustment:

The high-speed RPM and transition performance is adjusted with the high-speed “H” needle valve. When

adjusting, turn the screw about 1/8 of a turn each time. The position of the “H” needle will vary according to air

temperature and field elevation. If your engine is running smoothly, then do not adjust this needle valve.

Follow the recommended procedures if any of the following happens:

SPE-26˵Ã÷Êé-New.p65 2007-4-5, 17:575

Loading...

Loading...