Instruction and Operation Manual

- 11 -

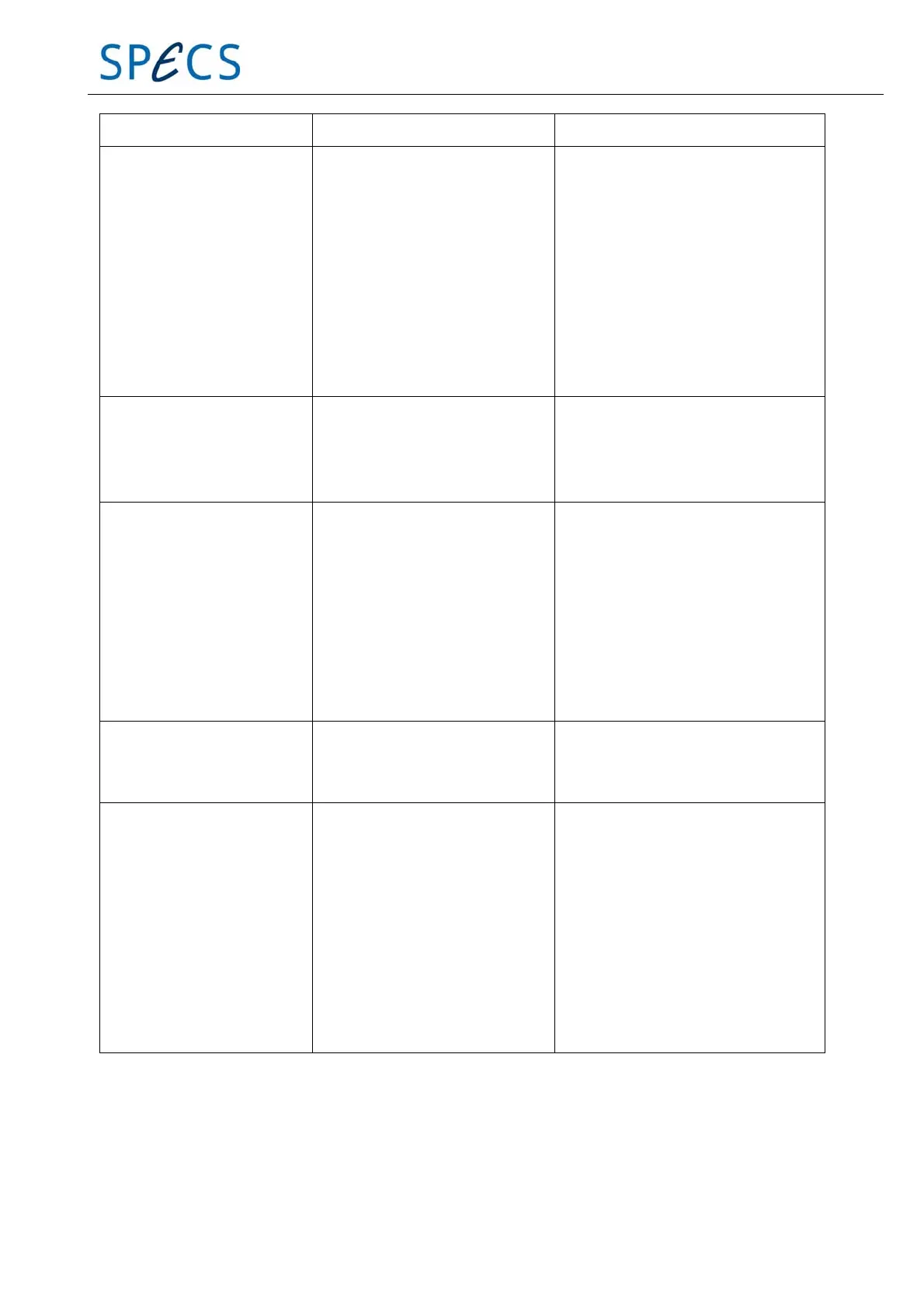

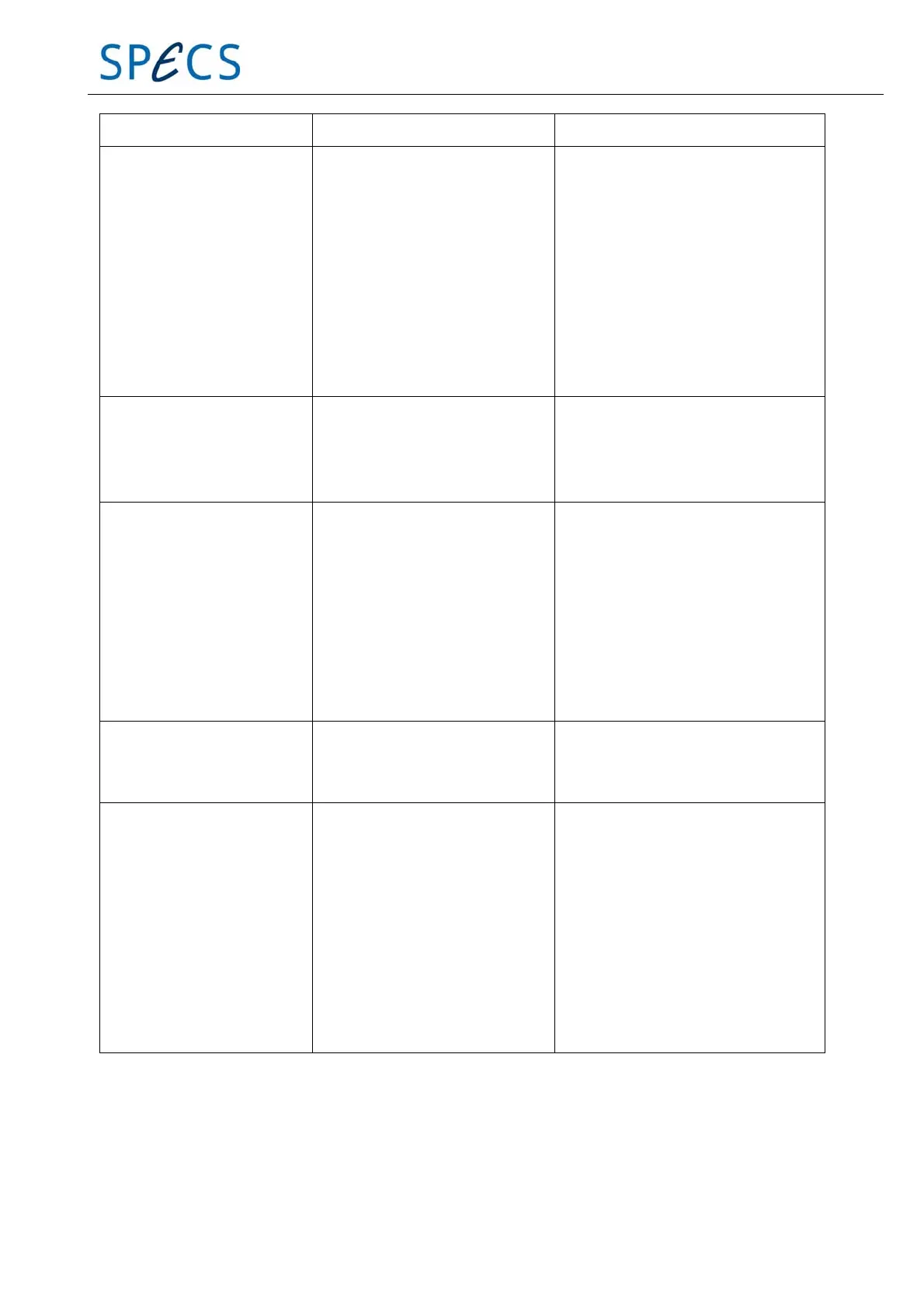

Failure (risk)

Cause Troubleshooting

Leakage of packing

1.

Gland flange nuts loose

2.

Rings of packing not

enough

3.

Packing aged or failure

4.

Stem sealing damaged

1.

Equally tighten eyebolt nuts

2.

Add packing

3.

Replace packing

4.

Stem shall be maintained

periodically by reparation or

replacement conjunction with

the maintenance of pipeline

Leakage between sealing

surfaces

1.

Dirties between sealing

surfaces

2.

Sealing surfaces damaged

1.

Clean sealing surface

2.

Repair the sealing surfaces

Operation failure

1.

Packing too tight

2.

Thread of stem nut over

worn

3.

Stem bent

4.

Foreigner existence between

stem and stem nut or gland

1.

Proper loose gland flange nuts

2.

Replace stem nut

3.

Rectify or replace stem

4.

Clean foreign matter

Leakage between bonnet

flanges

1.

Bonnet bolts loose

2.

Bonnet gasket failure

1.

Proper tighten bonnet nuts

2.

Replace bonnet gasket

Body and bonnet broken

and leaked

1.

Water hammer

2.

Fatigue

3.

Freezing broken

1.

Carefully operation to prevent

suddenly stopping pumping and

rapidly shutting

.

2.

Replace valve that exceeds

guarantee period or is found with

early fatigue defection

3.

Drain away water in winter

12.

Quality Warrant

12.1

SPECS warrants its valves

the date of delivery to the original customer, against defects in material and workmanship under

proper and normal use and service and not caused of resulting from improper

Loading...

Loading...