IM-P402-37 AB Issue 9 7

4. Installation

The probe consists of a metal rod

completely insulated from the liquid by

PTFE sheathing. It works by sensing the

variation in capacitance caused by a

change in water level, an increasing level

giving a proportionally increasing output.

The capacitance is measured by the

preamplifier and transmitted as a dc signal

to the controller or transmitter. Control and

switching levels are set in the controller.

The preamplifier sensitivity is selected

according to the immersed length of

the probe, and the wiring variations

that achieve this are described in the

preamplifier Installation and Maintenance

Instructions (IMI).

CAUTION: Over-tightening by hand or

use of a wrench will cause damage

to the 'O' ring and may damage the

preamplifier.

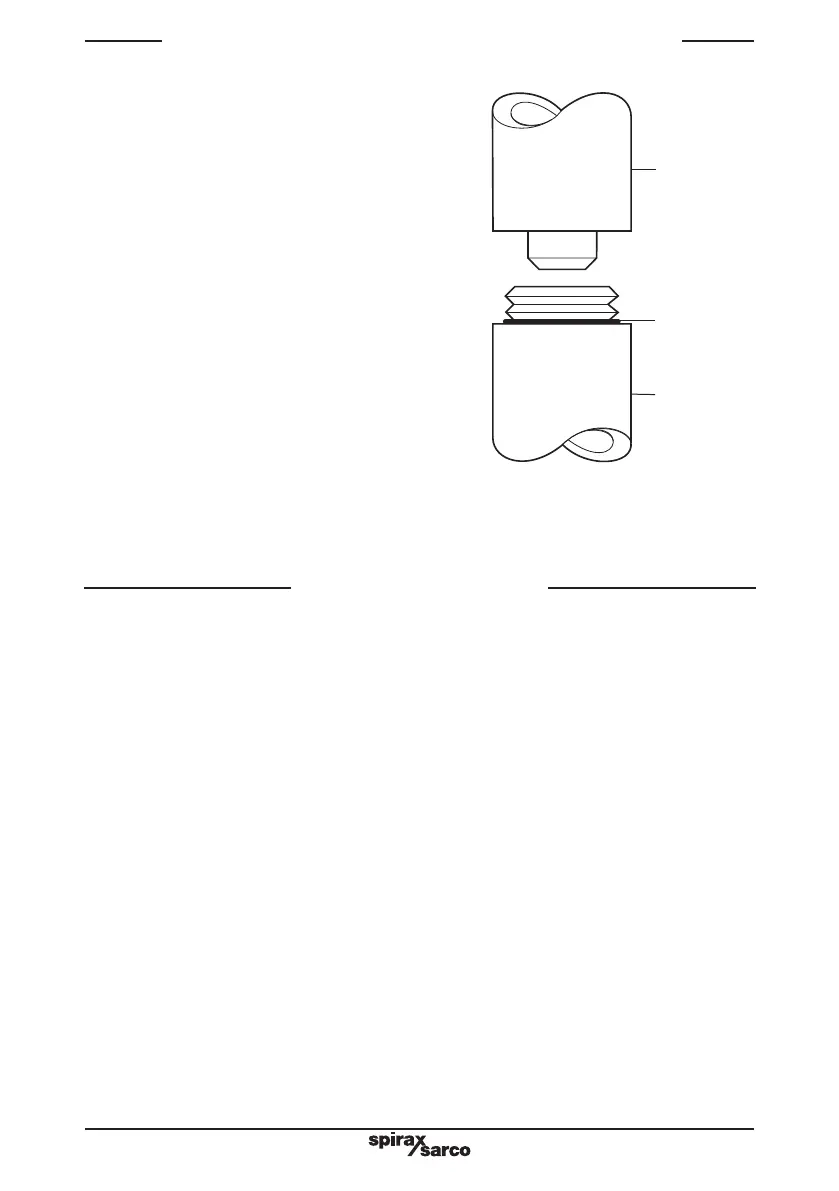

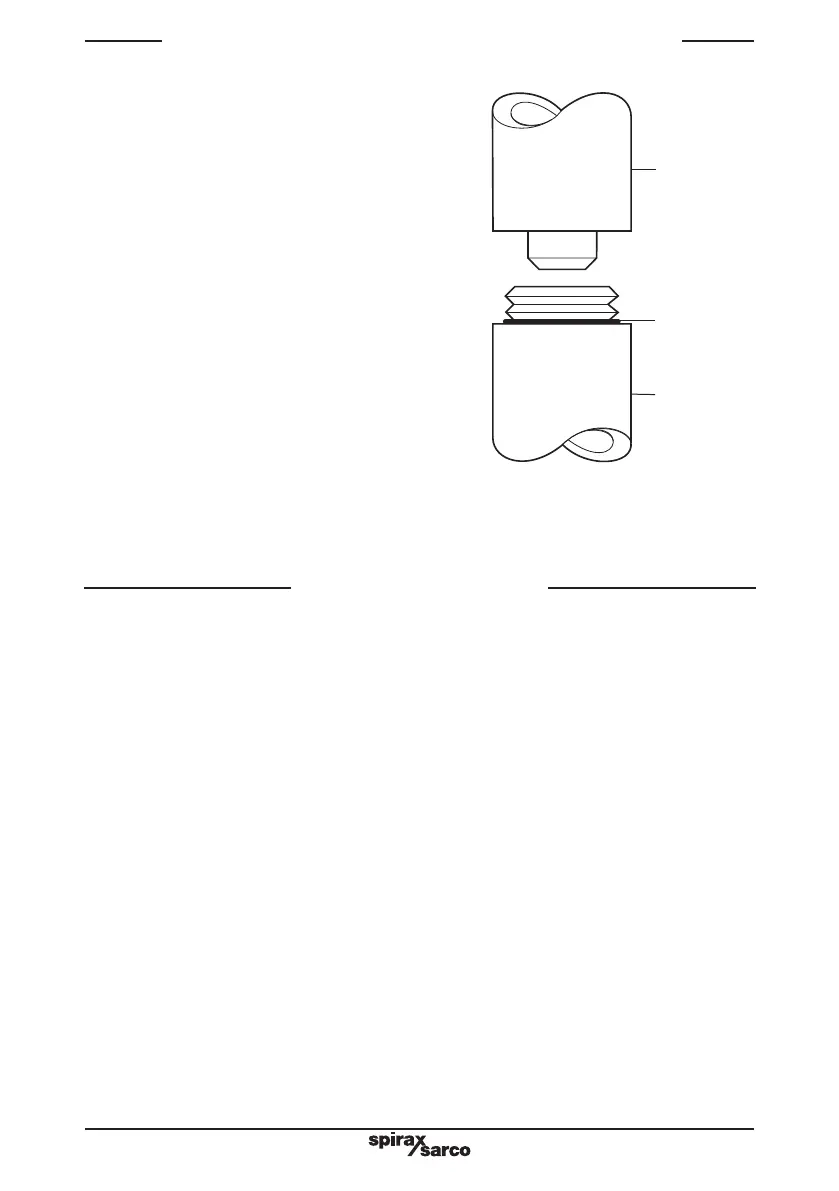

PA20

'O' ring

LP20

Capacitance

level probe

Fig. 2

WARNING: The LP20 probe must not be cut to length. Do not install the probe

outdoors without additional weather protection. Do not block the drain or the

vent holes.

A protection tube of 80 mm (3") nominal bore is required for boilers, or in tanks where

turbulence is likely. This should be as long as possible, and at least long enough to

cope with the expansion of the probe at maximum operating temperature (0 - 239°C,

32 - 462°F). Allow 20 mm (¾") clearance for probes up to 750 mm in length, and 38 mm

(1½" for longer probes).

4.1 Install the probs as follows

- Ensure both male and female threads are in good condition.

- Use up to three turns (no more) of PTFE thread sealing tape on the probe thread.

WARNINGS: Do not use excessive tape. Do not use paste type jointing compound.

- Fit and tighten the probe by hand initially - use a suitable spanner to tighten the probe.

Under no circumstances use a pipe wrench.

- Due to the nature of a taper / parallel joint it is not possible to recommend tightening

torque figures.

- Do not overtighten - there should always be visible thread on the probe.

- Note: The probe thread will not 'bottom out' (i.e. probe body hexagon contacts the

face of the female screwed connection), unless there is excessive wear or an

out-of-tolerance female thread, in which case it will be necessary to replace or re-work

the flange or connection. After installation ensure that resistance from the probe body

to the pipework / boiler shell is less than 1W.

3. How the LP20 probe works

Loading...

Loading...