sections each with its own TEV (no liquid line solenoid

valves) but handling the same load, two methods may be used

to avoid operating interference between sections:

1. Use a separate discharge bypass valve for each evaporator

section.

2. Use one discharge bypass valve to feed two bypass lines

each with a check valve between the bypass valve and the

evaporator section inlet. The check valves will prevent

interaction between the expansion valves when the bypass

valve is closed.

CAUTION - Introduction of the bypassed gas

between the thermostatic expansion valve and

the distributor is not generally recommended.

Hot gas flowing through the distributor nozzle

and circuit tubes, that were sized for normal cool-

ing flow rates, causes excessive pressure drop.

Careful evaluation and testing should precede

any application where hot gas is bypassed

between the TEV and the distributor.

BYPASS TO EVAPORATOR INLET

WITHOUT DISTRIBUTOR

Many refrigeration systems and water chillers do not use

refrigerant distributors, but may require some method of com-

pressor capacity control. This type of application provides the

same advantages as bypassing hot gas to the evaporator inlet

with a distributor. All information relating to bypassing hot

gas to the evaporator inlet with a distributor, except that con-

cerning distributors or ASC’s, also applies to bypassing to the

evaporator inlet without a distributor.

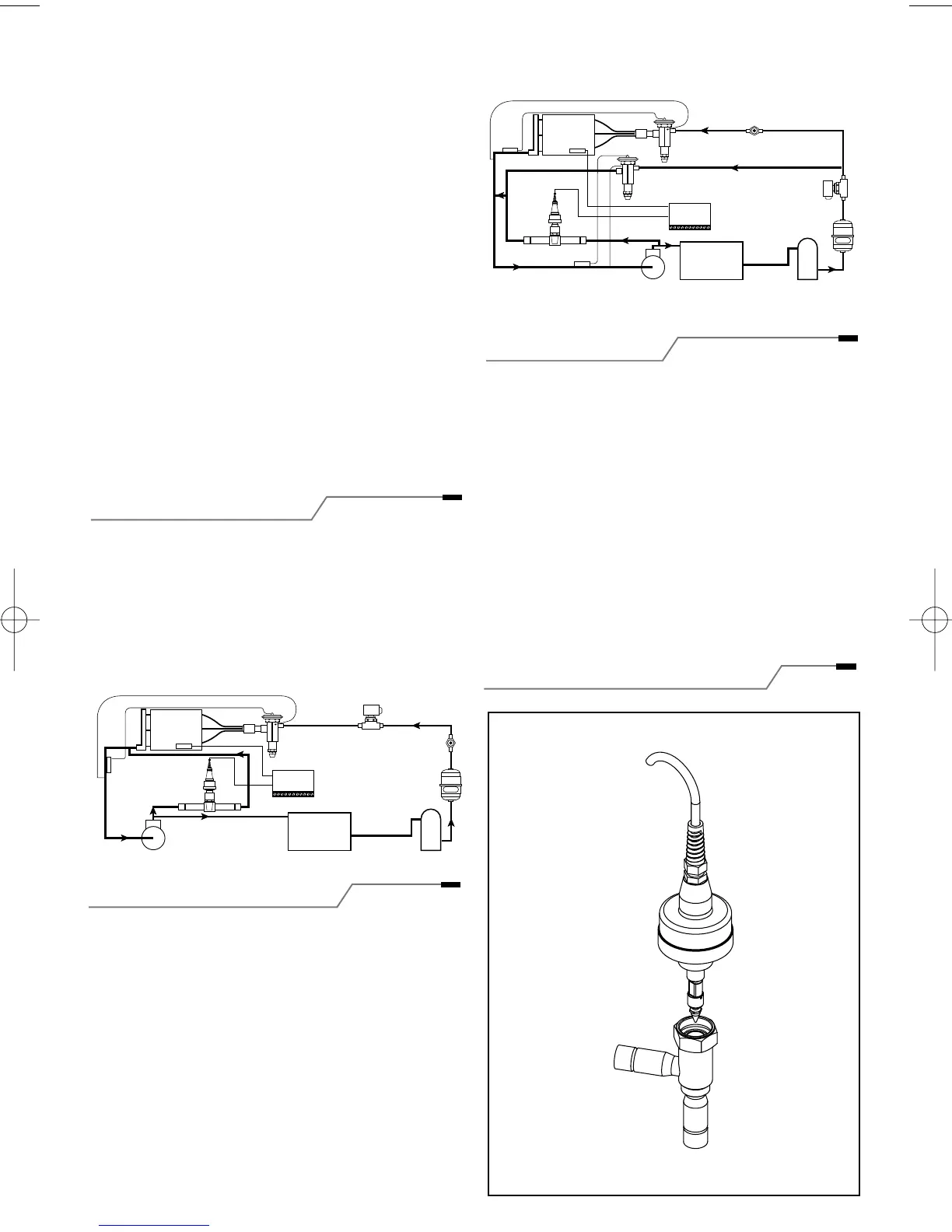

BYPASS TO SUCTION LINE

On many applications, it may be necessary to bypass directly

into the suction line (fig. 2). This is generally true of systems

with multi-evaporators or remote condensing units, as well as

on existing systems where it is easier to connect to the suction

line than the evaporator inlet. When hot gas is introduced

directly into the suction line, the danger of overheating the

compressor and trapping the oil in the evaporator exists. As

the suction temperatures rise, the discharge temperature like-

wise starts to increase. This can cause breakdown of the oil

and refrigerant with the possible result being a compressor

burnout. This method offers added flexibility for multi-evap-

orator systems or remote systems because the hot gas bypass

components can be located at the condensing unit. However,

to insure oil return, special care must be taken in the system

piping.

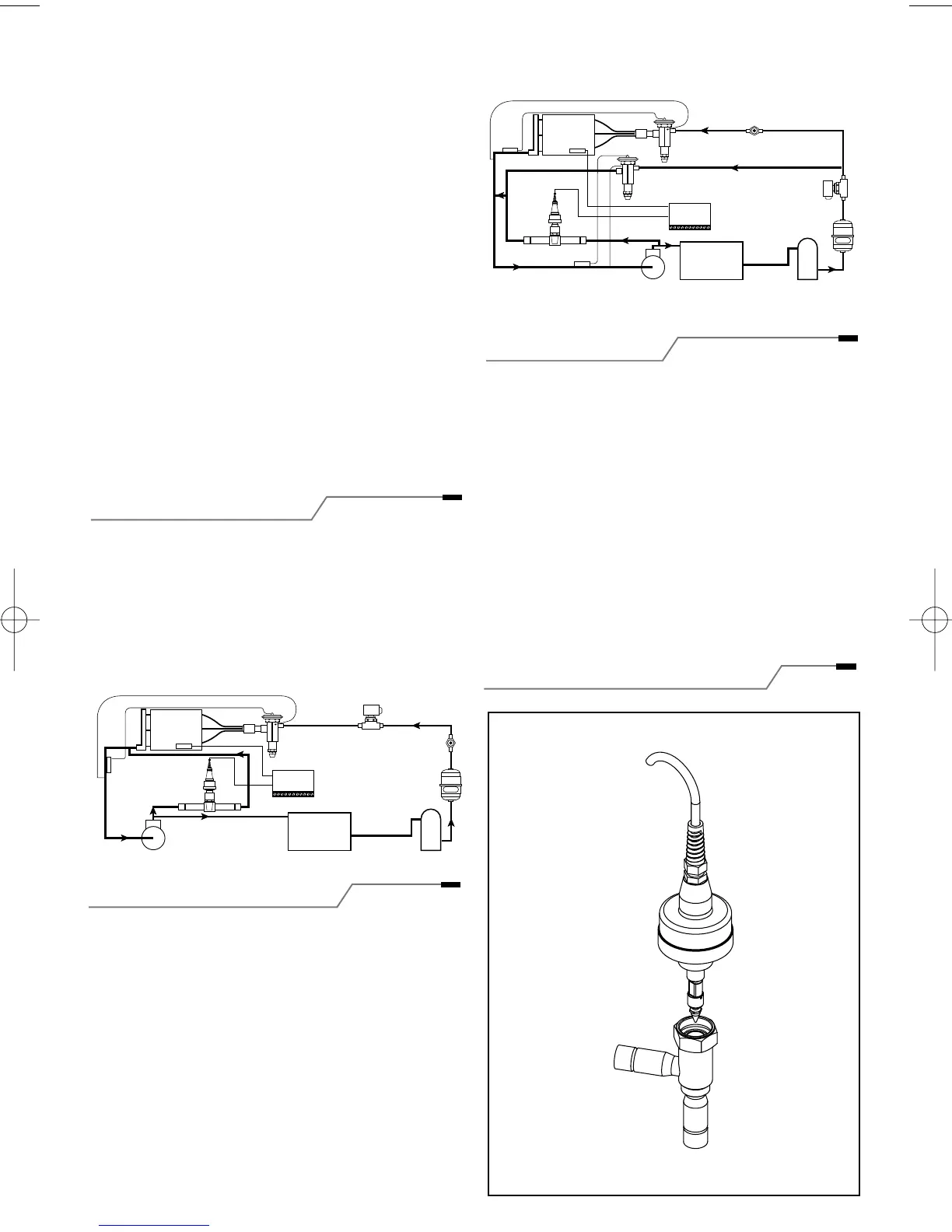

DESUPERHEATING THERMOSTATIC

EXPANSION VALVE

On those applications where the hot gas must be bypassed

directly into the suction line downstream of the main expan-

sion valve’s bulb, an auxiliary thermostatic expansion valve

(commonly called a desuperheating TEV or a liquid injection

valve) is required. The purpose of this valve is to supply

enough liquid refrigerant to cool the hot discharge gas to the

recommended suction temperature. Most compressor manu-

facturers specify a maximum suction gas temperature of 65°F.

For these requirements, special desuperheating thermostatic

charges are available which will control at the proper super-

heat to maintain the suction gas at or below 65°F. For appli-

cations requiring suction gas temperatures appreciably below

65°F, contact Sporlan Valve Company or the compressor man-

ufacturer for assistance. In all cases the maximum per-

missible suction gas temperature published by the

compressor manufacturer must be followed.

INSTALLATION INSTRUCTIONS

Loading...

Loading...