73

Technical Manual Gear Hub Systems 2010 · GEN.0000000002002 · Rev. A

SRAM

®

S7

MAINTENANCE

REASSEMBLY HUB

see Fig. 1

Lubrication see “

MAINTENANCE /

LUBRICATION

“.

• Insert into the axle (on the side with the

internal thread):

Short compression spring (21), thrust

block (20) – it is the same both sides, guide

rod (19) – it is the same both sides, long

compression spring (18).

• Compress spring and fit grub screw (17).

• Clamp axle, end with groove for

Clickbox facing upwards.

• Fit plastic profile washer (22) with its

large diameter upwards.

• Fit thrust washer (23) and retaining

washer (24).

• Locate cover (25), compression spring (26)

with 7 turns and cover (27, insides to the

spring).

• Compress spring and position thrust

block (28) – it is the same both sides –

centrally in the axle.

• Clamp other axle end (groove is facing

downwards).

• Fit large sun gear (15), with deflector

bevels upwards.

• Position medium sun gear (14), with

deflector bevels upwards.

• Fit small sun gear (13) – with recesses in

front, thrust block engages in the slots.

• Position smallest compression spring (12).

• Fit 1 mm thick washer (11).

• Fit planetary gear carrier (10):

Place the mounting aid(Fig. 2) on the

planetary gear carrier such that the

markings (X) on the 3 small planet gears

and the mounting aid match up.

• Turn planetary gear carrier and at the

same time push it downwards over the

sun gears.

• Fit thrust washer (9) and retaining

washer (8) in the undercut.

Now remove the mounting aid.

Advice:

If the gears are not accurately assembled

the hub may feel tight in use. This may

lead to gear wheel damage during travel.

• Clamp other axle end (groove for

Clickbox facing upwards).

• Fit coupling gear (29) with carrier plate

downwards

• Push ring gear (30) over the coupling

gear.

• Locate large spring (31).

• Fit largest ball retainer (34) with balls

underneath.

• Fit cover (32, inside to the spring).

• Assemble the compression spring (33)

with 12 turns.

• Position driver (35) – push it down – and

screw on fixed cone (36) to the stop,

tightening torque 20 Nm (177 in.lbs.).

• Clamp other axle end (groove for

Clickbox is facing downwards).

• Assemble hub shell (6) with a slight

counter-clockwise movement.

In case the hub shell jams, position the

plastic ring (Fig. 3) correctly. The plastic

ring is only fitted to some hub versions.

• Screw brake cone (7) clockwise onto

the planetary gear carrier (10) until it

stops.

• Insert 3 brake segments (5).

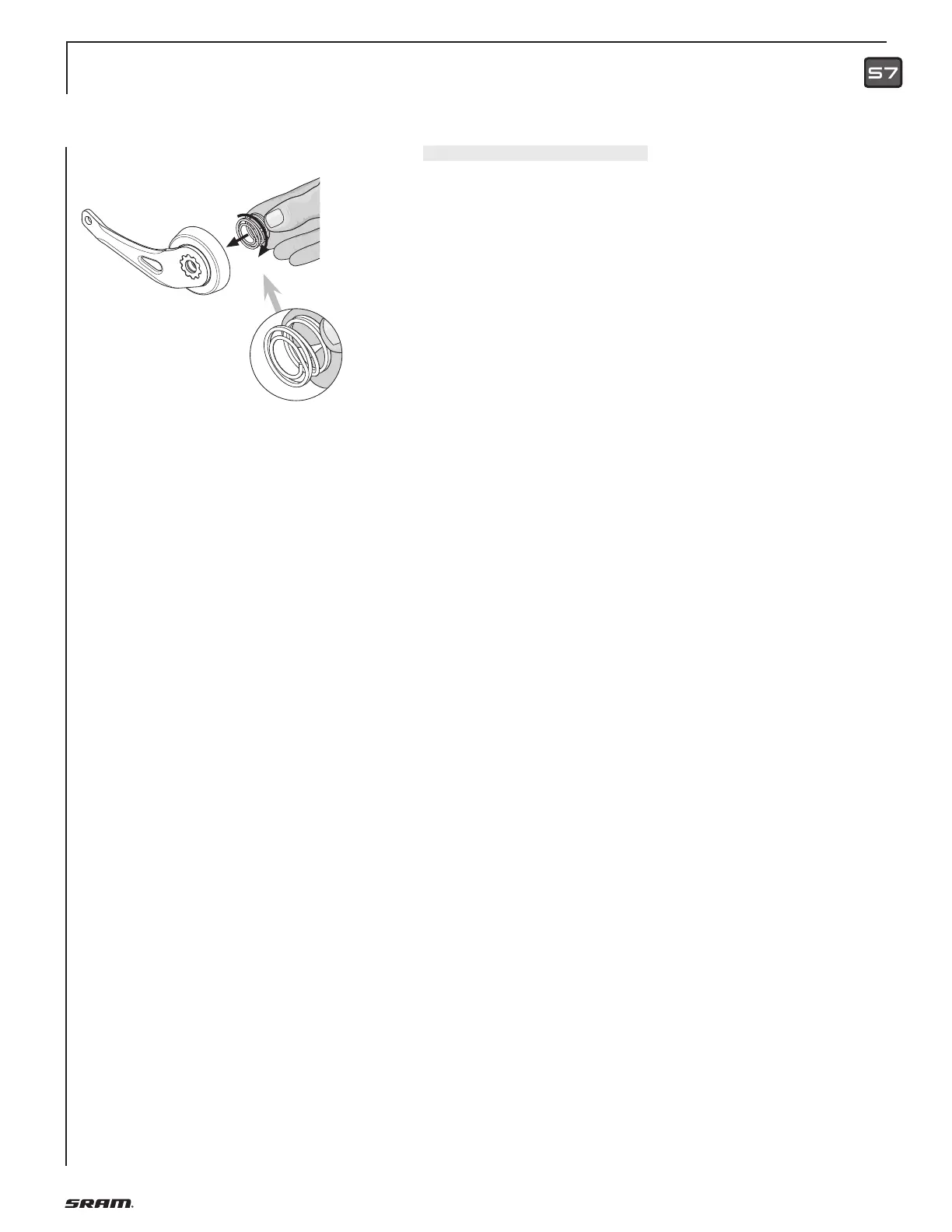

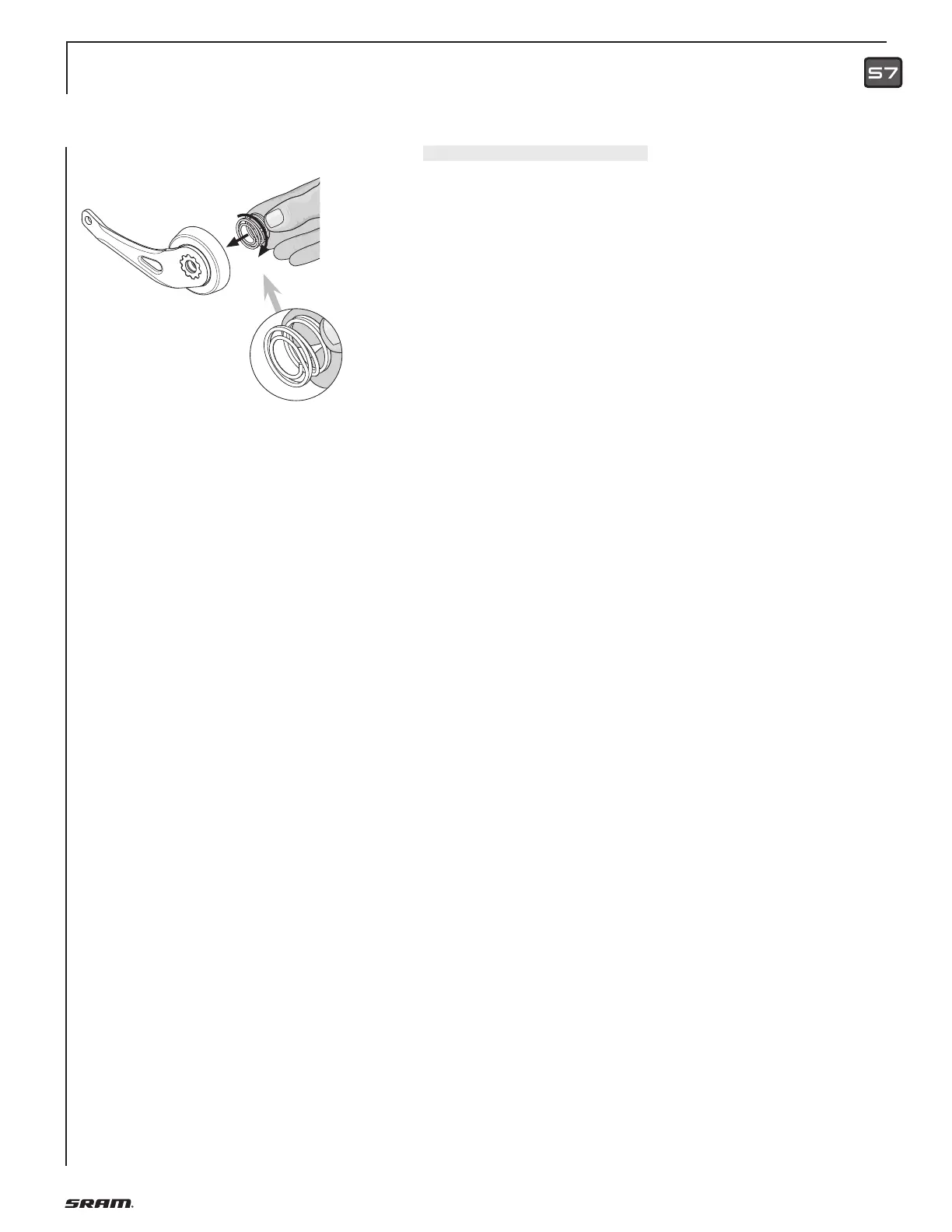

• Turn in friction spring (3) counterclock-

wise into the lever cone (2) (inlying

winding of the spring has to lie against

the lever cone) (Fig. 4).

• Insert ball retainer (4) (balls are facing

upwards) into lever cone (2): the 3 re-

cesses have to engage into the retaining

lugs of the lever cone. Slightly turn ball

retainer to prevent it from falling off.

• Fit lever cone onto hub shell: the

retaining lugs of the lever cone have to

engage into the openings between the

brake segments. Make sure that lever

cone engages while turning it back and

forth slightly.

• Screw on locknuts (1), adjust bearing

so that there is no play and lock nuts

together with 15 – 20 Nm (133 – 177in.lbs.).

Caution:

Check that all the brake system

components are functioning properly!

Advice:

Dismantling and reassembly of hub ver-

sion without brake should be carried out

in the same way.

Differences: Instead of brake segments /

cone a click-and-pawl carrier is installed

on the planetary gear carrier.

4

Loading...

Loading...