Solutions Strategies and Innovations

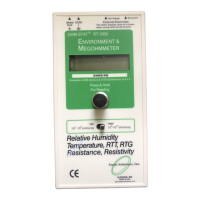

Static Solutions Inc. - Ohm - Stat RT - 1000 Information

Foreword

(This

foreword

is

not

part

of

ANSI/ESD

Association

Standard

S20-1.29099)

This standard covers the requirements necessary to design, establish, implement, and maintain an

Electrostatic Discharge (ESD) Control Program for activities that: manufacture, process, assemble, install,

package, label, service, test, inspect or otherwise handle electrical or electronic parts, assemblies and

equipment susceptible to damage by electrostatic discharges greater than or equal to 100 volts Human

Body Model (HBM). When handling devices susceptible to less than 100 volts HBM, more stringent ESD

Control Program Technical Requirements may be required, including adjustment of program Technical

Element Recommended Ranges. This document covers the control program requirements and offers

guidance to protect and handle ESD sensitive (ESDS) items, based on the historical experience of both

military and commercial organizations. References include, ESD Association, US Military and ANSI

approved standards for material properties and test methods. The fundamental ESD control principles

that form the basis of this document follow:

A. All conductors in the environment, including personnel, must be bonded or electrically

connected and attached to a known ground or contrived ground (as on shipboard or on

aircraft). This attachment creates an equipotential balance between all items and personnel.

Electrostatic protection can be maintained at a potential above a “zero” voltage ground

potential as long as all items in the system are at the same potential.

B. Necessary non-conductors in the environment cannot lose their electrostatic charge by

attachment to ground. Ionization systems provide neutralization of charges on these

necessary non-conductive items (circuit board materials and some device packages are

examples of necessary non-conductors). Assessment of the ESD hazard created by

electrostatic charges on the necessary non-conductors in the work place is required to ensure

that appropriate actions are implemented, commensurate with risk.

C. Transportation of ESDS items outside an Electrostatic Protected Area (hereafter referred

to as “Protected Area”) requires enclosure in static protective materials, although the type of

material depends on the situation and destination. Inside a Protected Area, low charging and

static dissipative materials may provide adequate protection. Outside a Protected Area, low

charging and static discharge shielding materials are recommended. While these materials

are not discussed in the document, it is important to recognize the differences in their

application.

Any relative motion and physical separation of materials or flow of solids, liquids, or particle-laden gases

can generate electrostatic charges. Common sources of ESD include personnel, items made from

common polymeric materials, and processing equipment. ESD can damage parts by direct contact with a

charged source or by electric fields emanating from charged objects that induce a charge on grounded or

capacitively coupled to ground sensitive items. It is possible to determine device and item susceptibility

by exposure to simulated electronic equivalent discharge circuits. The level of sensitivity determined by

test using these models may not necessarily relate to the level of sensitivity in a real life situation.

However, they are used to establish a baseline of susceptibility data for comparison of devices with

equivalent part numbers from different manufacturers. Three different models are used for

characterization of electronic components - Human Body Model (HBM), Machine Model (MM), and

Charged Device Model (CDM). It is important to recognize that these models, if used alone, are difficult to

apply in terms of specification setting activities. Examples of ESDS parts are microcircuits, discrete

semiconductors, thick and thin film resistors, hybrid devices and piezoelectric crystals.

Loading...

Loading...