ENGLISH

12

12

Set the direction of rotation for hammer drilling, drilling

and chiselling always to right rotation.

Switching On and O

To start the machine, press the On/O switch 7.

To lock the On/O switch, keep it pressed and additionally

push the lock-on button 6.

To switch o the machine, release the On/O switch 7.

When the On/O switch 7 is locked, press it rst and then

release it.

Setting the Speed/Impact Rate

The speed/impact rate of the switched on power tool can

be variably adjusted, depending on how far the On/O

switch 7/10 is pressed.

Light pressure on the On/O switch 7/10results in low

speed/impact rate. Further pressure on the switch

increases the speed/impact rate.

Safety Clutch

If the tool insert becomes caught or jammed, the

drive to the drill spindle is interrupted. Because of the

forces that occur, always hold the power tool rmly

with both hands and provide for a secure stance.

If the power tool jams, switch the machine o and

loosen the tool insert. When switching the machine

on with the drilling tool jammed, high reaction torques

can occur.

4.2 Working Advice

Changing the Chiselling Position

The chisel SDS can be locked in dierent positions.

In this manner, the optimum working position can be set

for each application.

Insert the chisel into the tool holder.

Turn the mode selector switch 8

Turn the tool holder to the desired chiselling position.

Turn the mode selector switch 8 to the “chiseling” position.

The tool holder is now locked.

For chiselling, set the rotation direction to right rotation.

Switching On/O: A

To start the machine, press the On/O switch 6 and keep

it depressed.

To switch o the machine, release the On/O switch 6.

Switching On/O: B (g. 19).

To start the machine, press the On/O switch 6/7 at the

top ( I ) until it locks.

To switch o the machine, press the On/O switch 6/7 at

the bottom (O) and release it.

For low temperatures, the power tool reaches the full

hammer/impact capacity only after a certain time.

Setting the Speed/Impact Rate

The electronic control 10 enables stepless speed and

impact preselection in accordance with the material to be

worked.

The maximum hammering capacity is achieved when the

thumbwheel 10 is set to position “6”.

For lower speed settings, the hammering capacity is lower

due to technical reasons.

Setting the Impact Rate HD3BE K

You can set the impact rate of the switched on power tool

continuously, depending on how far you press down the

On/O switch 7.Slight pressure on the On/O switch 7

causes a low impact rate. Stronger pressure increases

the impact rate.

OPERATION MD15K

4.3 Starting Operation

Observe correct mains voltage! The voltage of

the power source must agree with the voltage

specied on the nameplate of the machine.

Power tools marked with 230V can also be

operated with 220V.

Switching On and O

To start the machine, push the On/O switch 6/7 to the “I”

position.

To switch o the machine, push the On/O switch 6/7 to

the “O” position.

For low temperatures, the machine reaches the full impact

rate only after a certain time.

This start-up time can be shortened by striking the chisel

in the machine against the oor one time.

4.4 Operating Instructions

While working, hold the power tool with both hands by the

handle 1.

For the highest possible impact damping, work only with

moderate pressure.

5. Maintenance and Service

5.1 Maintenance and Cleaning

Before any work on the machine itself, pull the mains

plug.

For safe and proper working, always keep the machine

and ventilation slots clean.

A damaged dust protection cap should be changed

immediately. We recommend having this carried out

by an after-sales service.

Clean the tool holder 2 each time after using.

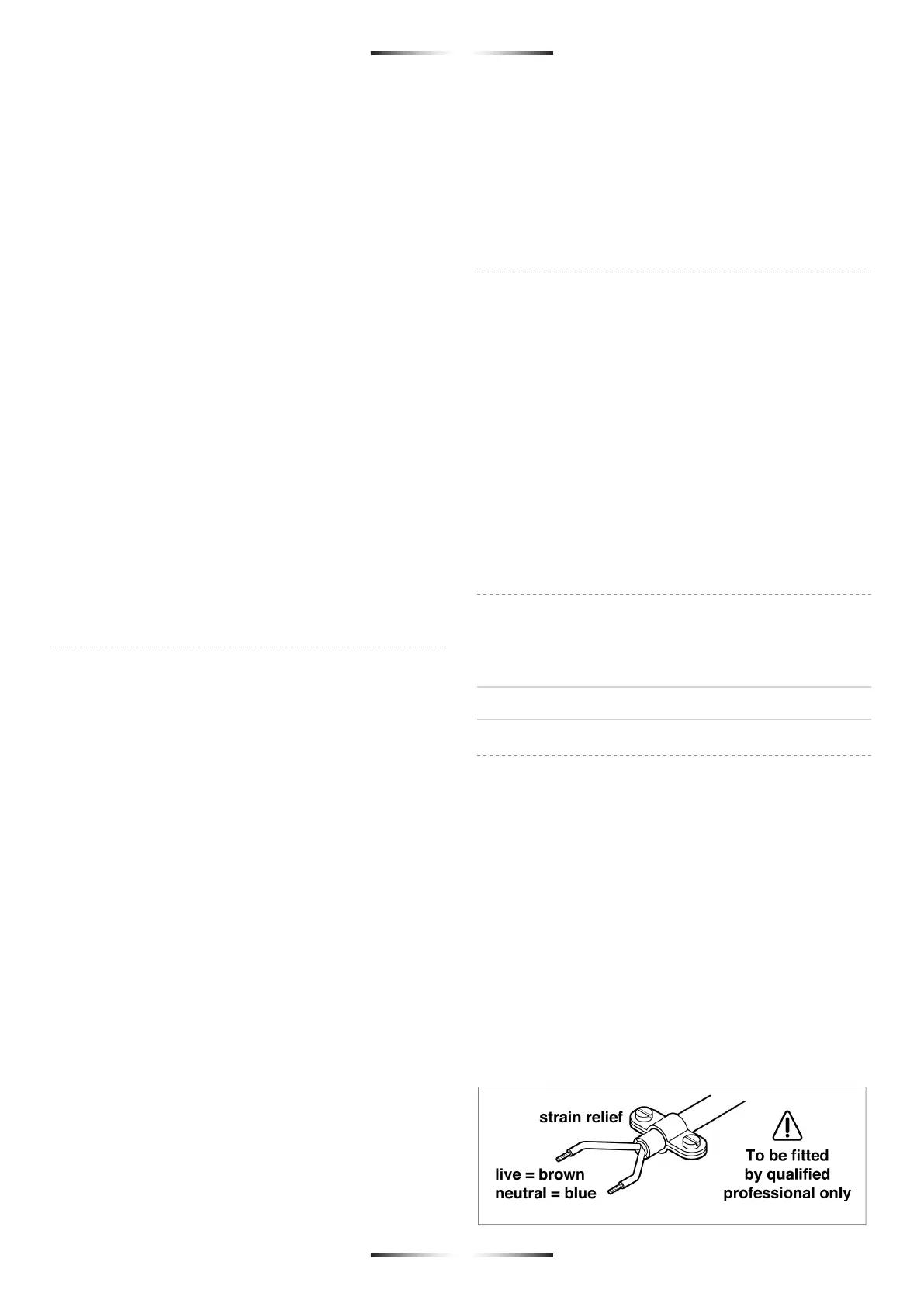

WARNING! Important instructions for

connecting a new 3-pin plug to the 2-wire

cable.

The wires in the cable are coloured according to the

following code:

Loading...

Loading...