06/14

Pub. No. 908-F

- 3 -

Electric Steam Cleaner Model: HPJ-2S

Installation and Operating Instructions

TROUBLESHOOTING YOUR STEAM ASTER

MODEL HPJ-2S

When starting up, machine fails to operate:

1. Check to see if plug is in electrical outlet. Is outlet good?

2. Check fuses in your main power supply.

3. Recheck your start-up operation steps.

Machine cuts off while operating:

A low water condition can activate Manual Reset Low Water

Cut-Off Switch, reset light will come on. If this should

happen, follow this procedure.

1. Bleed out all steam pressure in generator.

2. Fill water up to high level mark on Glass Gauge.

3. Push Reset Button on side of machine.

NOTE: Reset Button is to be used ONLY when machine

cuts-off due to a low water condition!

(When low water cut off is activated) under normal

conditions it is not necessary to use reset button.

4. Pilot Light will go on indicating that machine is now

operational.

IMPORTANT! If Pilot Light fails to go on after following

above instructions, check fuses in your main power supply.

Condensation forms each time machine is used:

This is a normal condition. Always depress lever of Steam

Release Pedal Valve for about five seconds to remove

excess condensation at each usage.

MAINTENANCE INFORMATION

During the first week of operation only, drain boiler at least

every other day. In order to extend the life of the machine,

drain boiler at least once each week under 10 Ibs. of steam

pressure, with electric current turned off.

After draining, flush out boiler with plain water, then refill

machine to high level mark on Glass Gauge. Drain Valve is

located on lower left side of the machine.

The exterior metal cabinet and parts should be wiped off

on a regular basis with a damp cloth to maintain the new

appearance of the machine. Do not allow the parts to

become clogged with dirt and grime.

IMPORTANT! Water in machine MUST always be kept

above LOW level mark on Glass Gauge (½" from bottom of

Glass Gauge) in order to protect and extend the operating

life of the heating element.

WARNING: Steam slowly erodes the sight glass. To

prevent the sudden breakage or explosion of the gauge

glass. It must be inspected on a regular basis for signs of

deterioration.

Sight Glass Inspection: The sight glass should be

inspected for deterioration each time the unit is refilled.

Scratches, corrosion, chips, surface flaws, cracks, or nicks

weaken the glass. To examine for these imperfections shine

a very bright concentrated light at about 45 degree angle.

Anything which glistens and catches the fingernail or any

star-shaped or crescent-shaped mark which glistens is

cause for replacement. Any gauge glass which appears

cloudy or roughened and cannot be cleaned with commercial

glass cleaners, should be replaced.

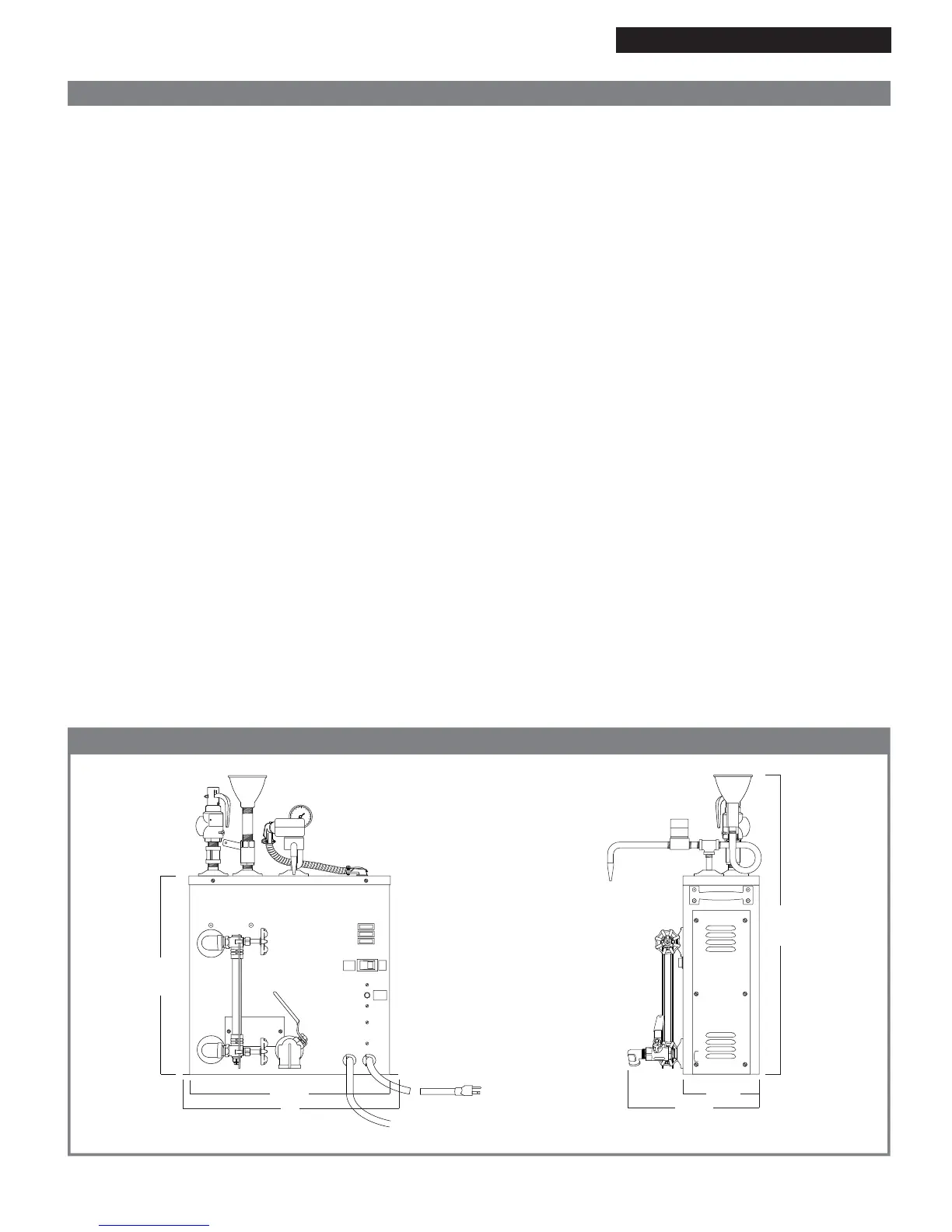

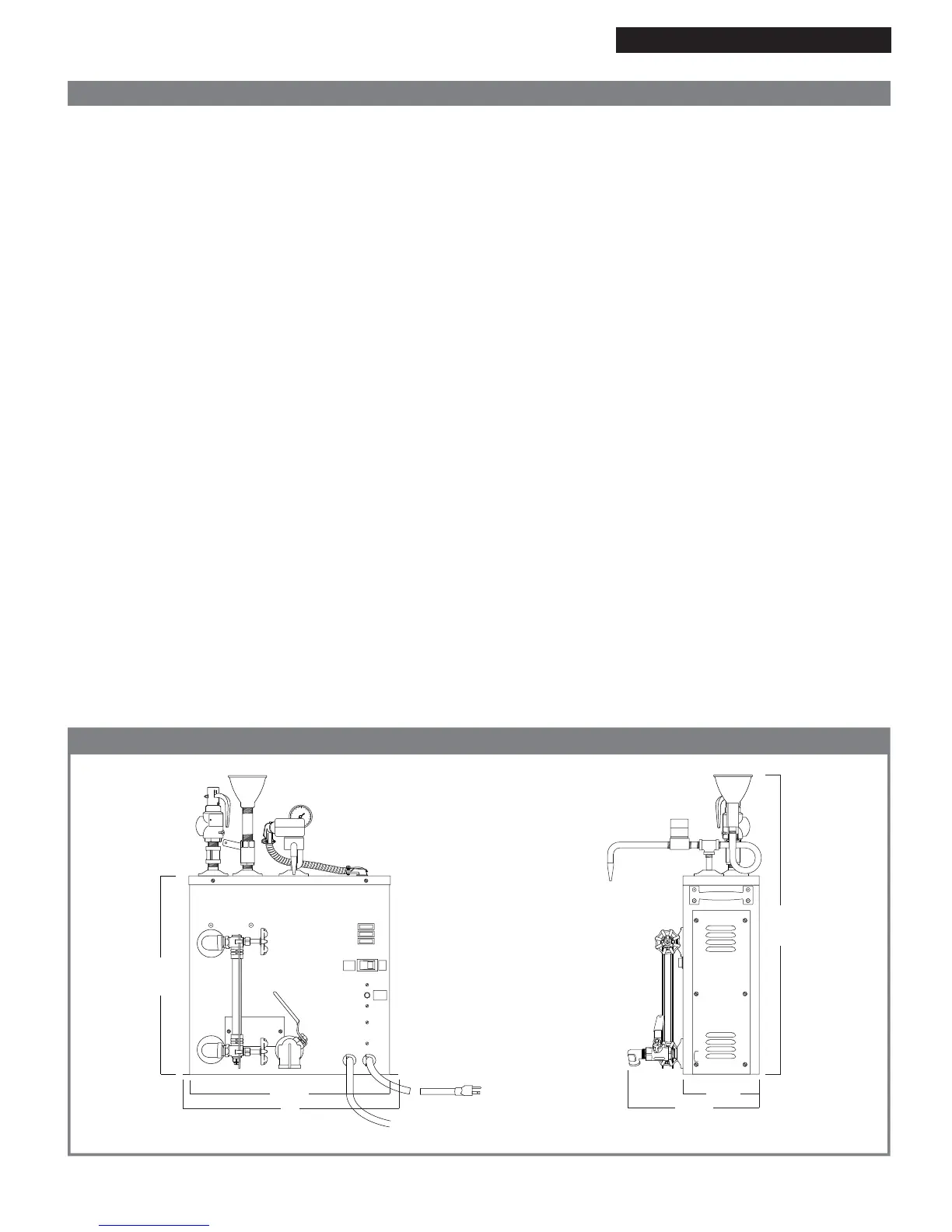

80

100

120

140

60

40

20

0

psi

FILL/STEAM

HEATING

RESET

HEAT

CYCLE

OFF

MANUAL

RESET

16 3/4"

18"

16 3/4"

25 1/2"

6 1/2"

11 1/2"

Model HPJ-2S - General Arrangement

Loading...

Loading...