91

ENGLISH

EN

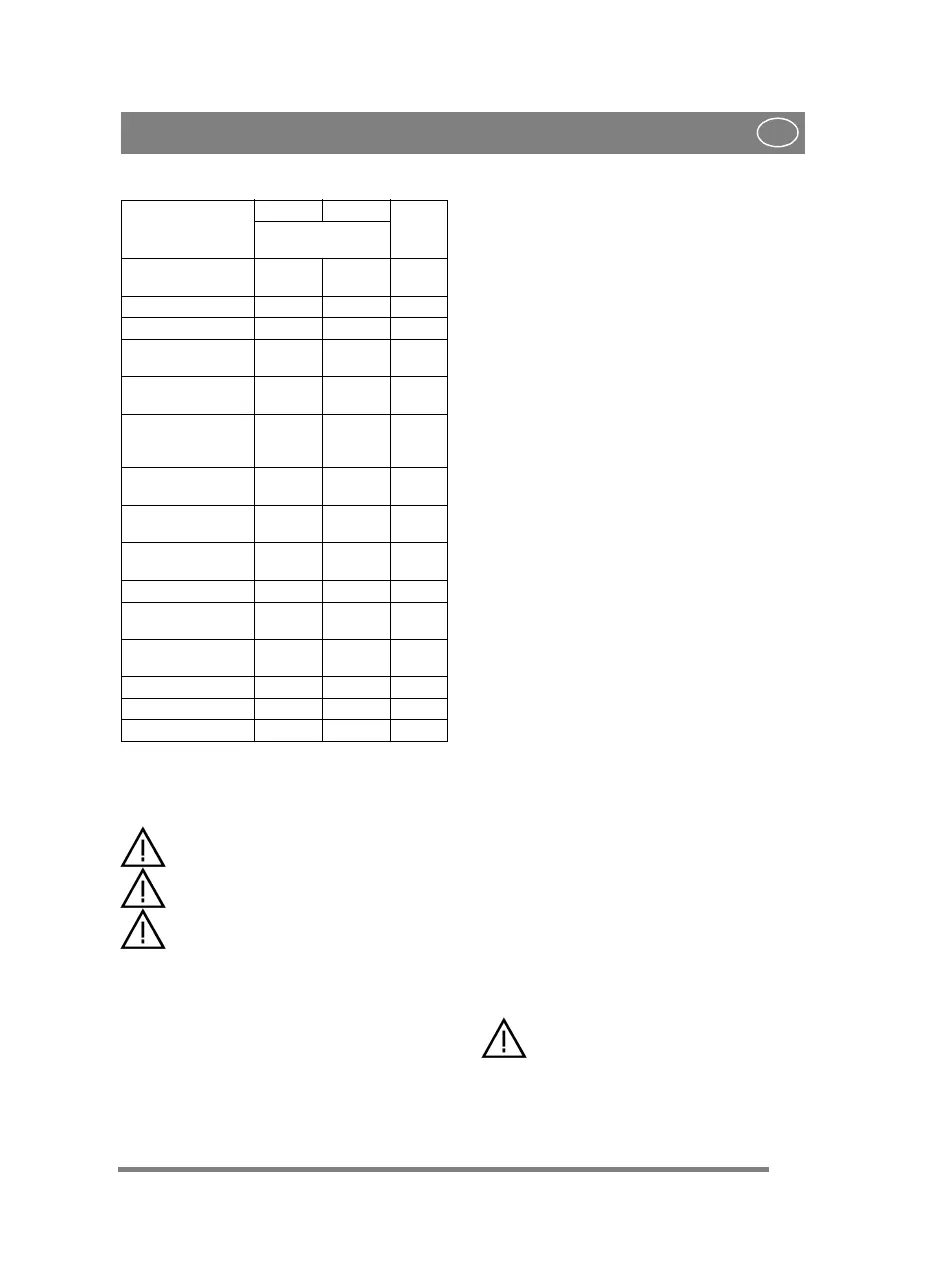

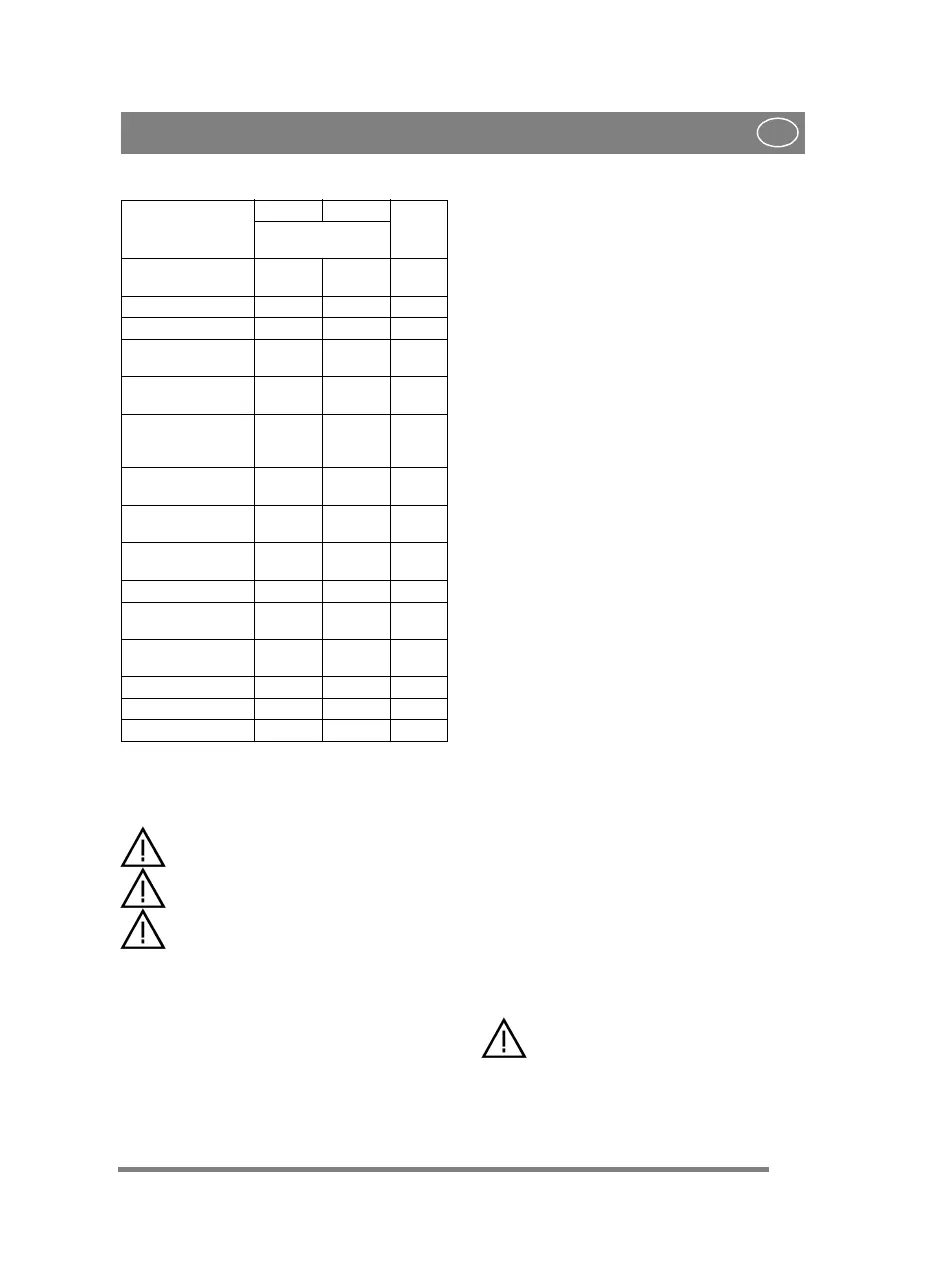

6.2 SERVICE POINTS.

6.3 PREPARATION

All service and all maintenance must be carried out

on a stationary machine with the engine switched

off.

Prevent the machine from rolling by

always applying the parking brake.

Stop the engine.

Prevent unintentional starting of the

engine by removing the ignition key.

6.4 WATER SEPARATOR

There is a float in the water separator (17:E) that

can be viewed through the transparent cup. The

float must be at the bottom. If the float has risen,

the water separator must be cleaned as follows:

1. Shut off the water separator tap. See fig. 17.

2. Hold a container under the water separator to

collect fuel.

3. Open the cup by pressing its ring (17:A).

4. Carefully remove the cup (17:B) and remove

the spring (17:D) and float (17:E) from the cup.

5. Clean the inside of the cup and thread filter

(17:C).

6. Check that the O-ring is intact and reinstall the

components in reverse order.

7. Open the tap.

8. Bleed the fuel system. See “5.12”.

Clean the fuel tank if water accumulates in the wa-

ter separator often. Contact an authorised work-

shop.

6.5 FUEL FILTER (26B, 26H)

1. Shut off the fuel filter’s tap. See fig. 18.

2. Hold a container under the fuel filter to collect

fuel.

3. Detach the cup by turning its ring (18:J).

4. Carefully remove the cup (18:H) and remove

the filter (18:F).

5. Clean the inside of the cup (18:H).

6. Check that the O-ring (18:G) is intact and rein-

stall the components with new filter in reverse

order.

7. Open the tap.

8. Bleed the fuel system. See “5.12”.

6.6 FUEL FILTER (32H)

1. Stop the engine and allow it to cool.

2. Close all the fuel taps.

3. Use an oil filter wrench to slacken off the filter

(19, 20:P) in the direction (19:Dis). Carefully

remove the filter to prevent the spillage of fuel.

Wipe up any spilled fuel.

4. Clean around the mounting surface of the filter.

5. Apply a thin layer of fuel to the new filter gas-

ket.

6. Install the new filter by rotating it in the direc-

tion (19:Ass) until the gasket comes into con-

tact with the mounting surface.

7. Then tighten the filter a further turn using the

filter wrench.

6.7 TYRE PRESSURE

Set the tyre pressures to their default pressures.

Pressure front and rear: 0.9 bar.

See pressures in the manual for relevant imple-

ment.

6.8 CHANGING ENGINE OIL, FILTER

The engine oil may be very hot if it is

drained off directly after the engine is

shut off. So allow the engine to cool a

few minutes before draining the oil.

Change engine oil and filter as follows:

1. Place the machine on a level surface and run the

engine to operating temperature.

Service point

1st time Interval See

para-

graph

Hours of operation/

Calendar months

Water separator,

check

50/- 6.4

Pre-filter, cleaning 6.4

Fuel filter, replace 400/- 6.5

Tyre pressure,

check, adjust

6.7

Engine oil, filter,

change

50/12 200/12 6.8

Hydraulic oil, fil-

ter, tank vent valve,

change/clean

50/12 400/12 6.9

Wheel motors ,

change oil

50/12 200/12 6.10

Belt transmissions,

check

50 200/- 6.11

Cooling system,

clean

1000/12 6.12

Battery, check 50/- 6.13

Air filter, clean pre-

filter

6.14

Air filter, change

inner filter

6.14

Lubrication 6.15

Adjusting valves 1000/- 6.16

Grinding valves 2000/- 6.16

Loading...

Loading...