KM 90 R

English

26

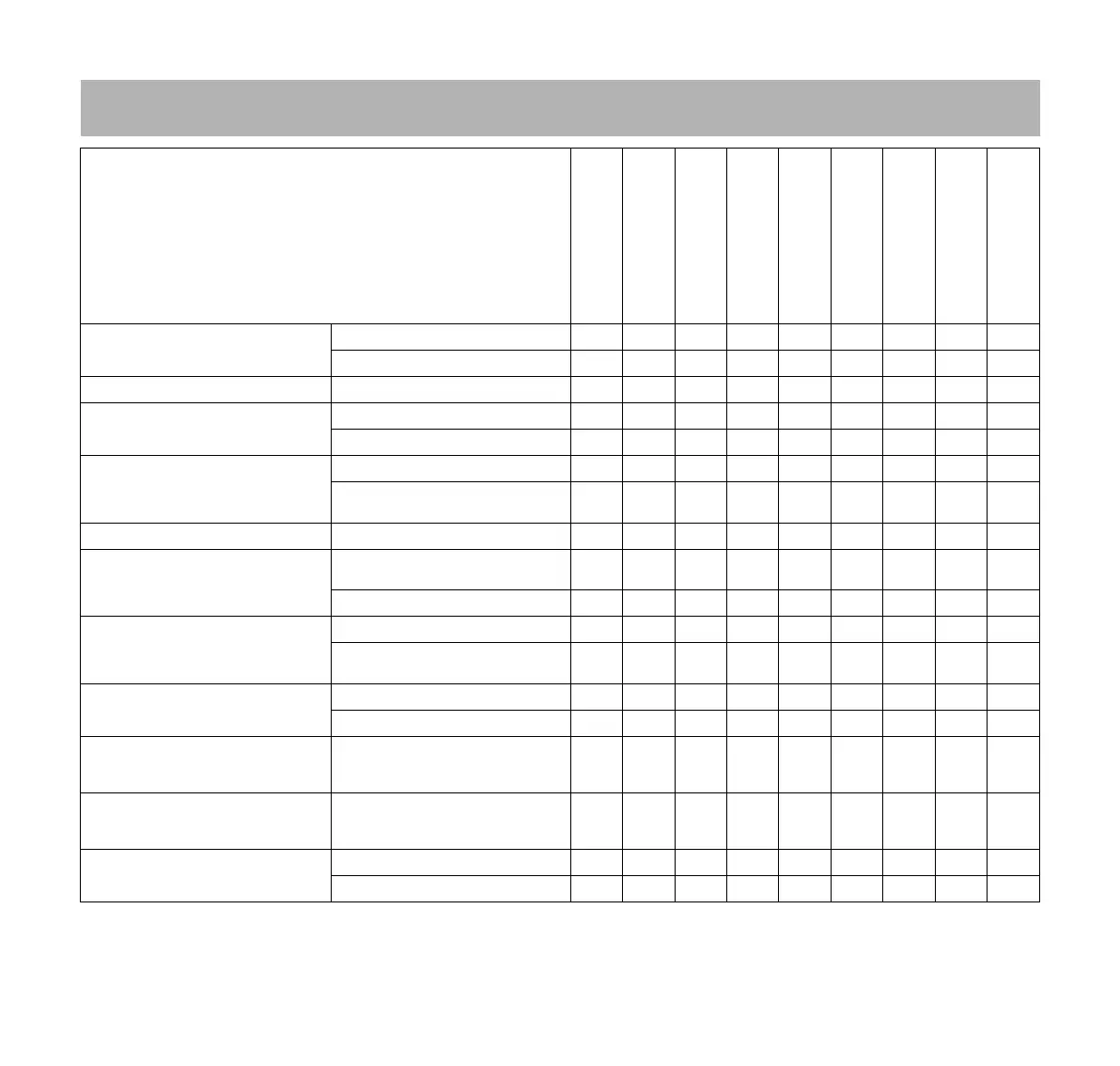

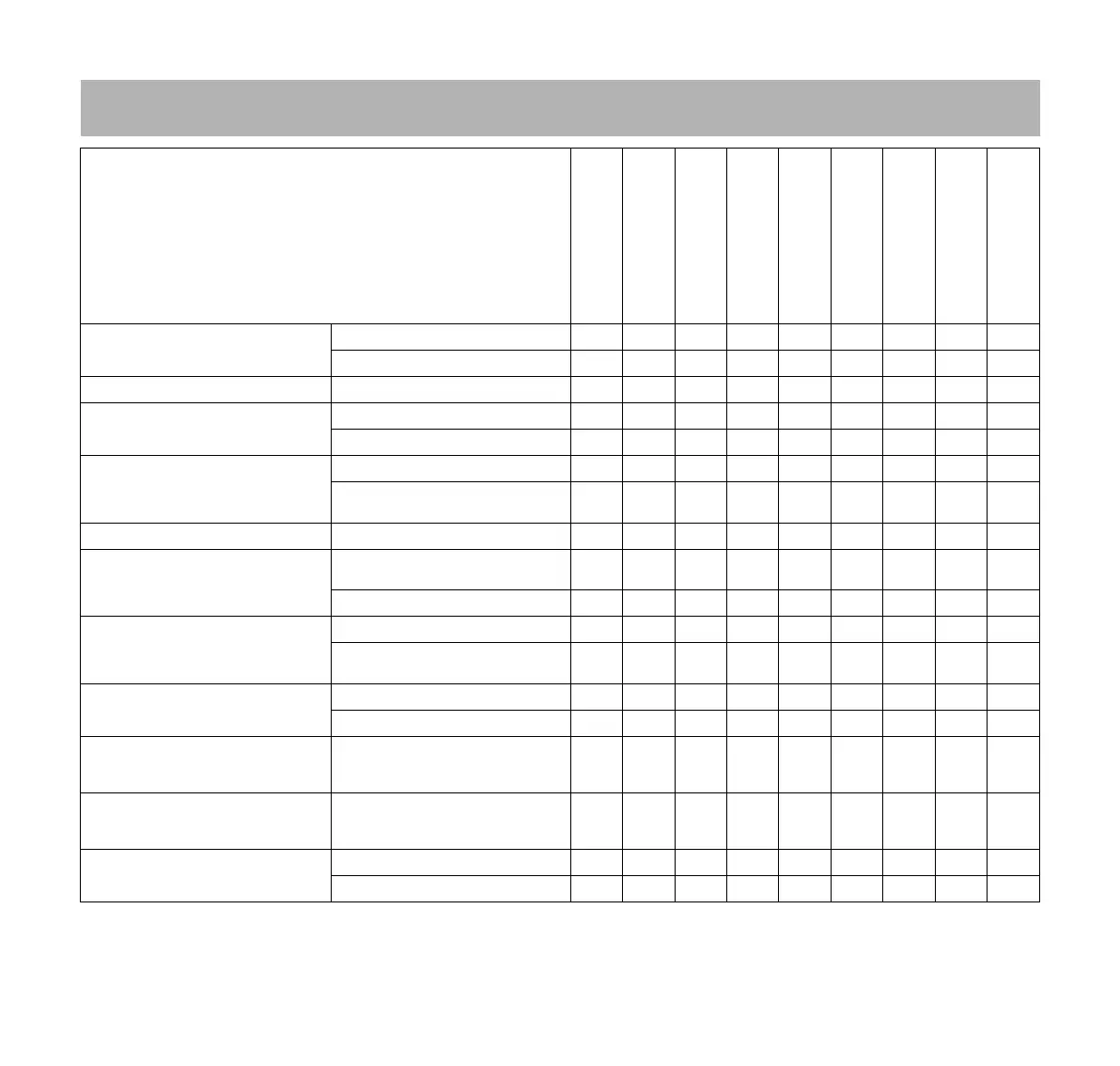

Maintenance and Care

The following maintenance intervals apply in normal operating conditions. The spec-

ified intervals must be shortened accordingly when working for longer than normal

or under difficult cutting conditions (extensive dust, etc.).

before starting work

at the end of work and/or

daily

whenever tank is refilled

weekly

monthly

yearly

if faulty

if damaged

as required

Complete machine

Visual inspection (condition, leaks) XX

clean X

Control handle check operation XX

Air filter

clean XX

replace X

Fuel pick-up body in fuel tank

Have checked by a specialist dealer

1)

X

have them replaced by a specialist

dealer

1)

XXX

Fuel tank clean XX

Carburetor

Check idle adjustment, the working tool

must not turn

XX

Set idle speed X

Spark plug

Set electrode gap X

replace after every 100 hours of

operation

Intake port for cooling air

Visual inspection X

clean X

Valve clearance

Check and adjust if necessary, one time

after 139 hours of operation, by servic-

ing dealer

1)

X

Combustion chamber

Decarbonize after 139 hours of opera-

tion, subsequently after every 150 hours

of operation

X

Spark arresting screen in muffler

check XX

Clean or replace XX

Loading...

Loading...