,-

Important:

The four M4 allen screws

(

3

ln fig. 8

)

should

not be

tightened

until

the two taper locating

pins (

2 in

fig. 8

)

have been

fltted.

Do not check the eccentrlclty of the capstan wlthout

pinch-wheel pressure

applled, as

bearing

play

may cause erroneous

readings.

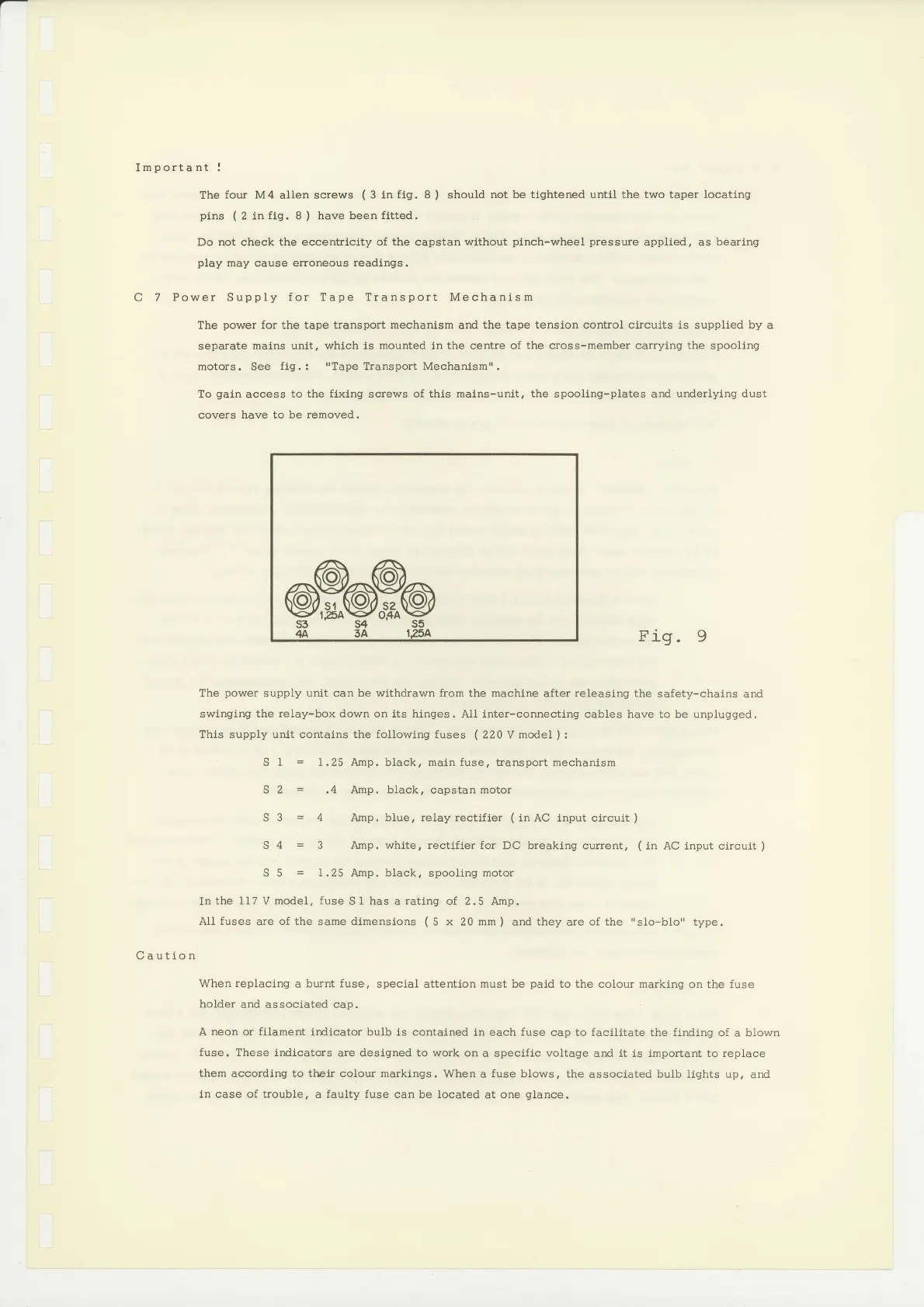

C

7 Power Supply

for

Tape

Transport Mechanism

The

power

for the tape transport mechanism

and

the tape tenslon control clrcults ls supplled by a

separate

malns unlt, whlch is

mounted

in

the

centre

of the

cross-member

carrying the

spooling

motors.

See

fig.:

"Tape

Transport Mechanism".

To

gain

access

to the flxlng screws of this mains-unit,

the

spooling-plates and underlying dust

covers have to be

removed.

Fig.9

Caution

The

power

supply

unit can be wlthdrawn from

the machlne

after

releasing the

safety-chains

and

swlnging the

relay-box

down on its hinges. AII inter-connecting

cables have to be unplugged.

This supply unlt contains the following fuses

(

220 V

model

):

S

I

=

1.25

Amp. black, main fuse, transport mechanism

S

2

=

.4 Amp, black, capstan motor

S 3

=

4 Amp, blue, relayrectifier

(lnAC

lnputcircuit)

S

4

=

3

Amp.

whlte, rectifier

for DC breaklng

current,

(

in AC input circuit

)

S 5

=

1.25 Amp. black,

spooling

motor

In

the 1I7

V

model, fuse

S t has a rating of

2.5 Amp.

AII fuses

are

of

the same dimensions

(

5

x

20

mm

)

and

they

are of the

"slo-blo"

type.

When

replacing

a

burnt fuse,

speclal attention must be

paid

to the

colour

marking

on the fuse

holder

and associated cap.

A

neon

or filament irdicator bulb is contalned

ln each fuse cap to facilitate

the

finding

of a blown

fuse, These

indlcators are deslgned to work on

a specific

voltage

and

it is important

to replace

them according to their colour marklngs,

When a

fuse

blows, the

associated bulb lights up,

and

ln case

of

trouble, a

faulty

fuse can

be located at one

glance.

Loading...

Loading...