8-16

Troubleshooting Guides

7011902 - Revision A - October, 2009

International Integrated

International Integrated

(ICB700 Base)

(ICB700 Base)

Series

Series

ICB700BR

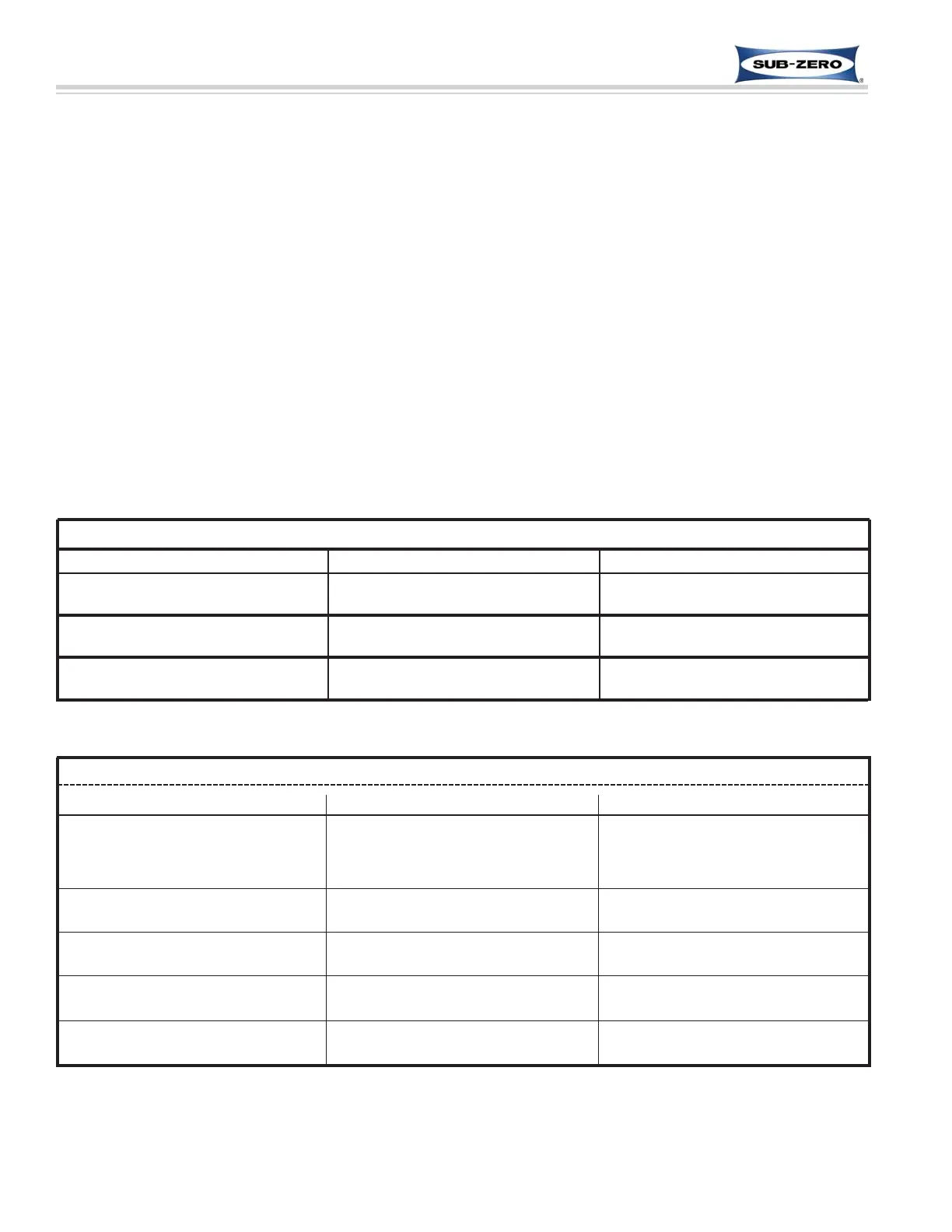

0 - 12 psi to 30 - 42 psi 75 psi to 110 psi

ICB700BF/I

5” Vac - 1 psi to 6 - 12 psi 75 psi to 120 psi

SEALED SYSTEM TROUBLESHOOTING / DIAGNOSTICS TABLES

NORMAL OPERATING PRESSURES TABLE NOTES:

• Only enter the sealed system to check pressures if the Error Code Troubleshooting Guide and General

Troubleshooting Guide could not pinpoint the cause of the temperature problem.

• Always use solder-on process valves when entering the sealed system. Do NOT use bolt-on process valves as

they are prone to leak.

• Whenever servicing the sealed system, the high-side filter-drier MUST be replaced.

• Pressures listed below are not indicative of initial pull down, but rather of a steadily running and properly function-

ing appliance.

• Pressures listed are for reference only, as actual pressure readings may vary because of one or more of the fol-

lowing reasons:

1. Ambient temperatures (Pressures are based on a 21°C (70°F) Ambient).

2. Temperature set-points (Pressures listed below are based on set-points of -18°C (0°F) in freezers and 3°C

(38°F) in refrigerators)

3. Food load quantity and temperature.

4. Condenser cleanliness.

5. Whether or not one or both refrigeration systems are operating.

6. Gauge calibration.

NORMAL OPERATING PRESSURES

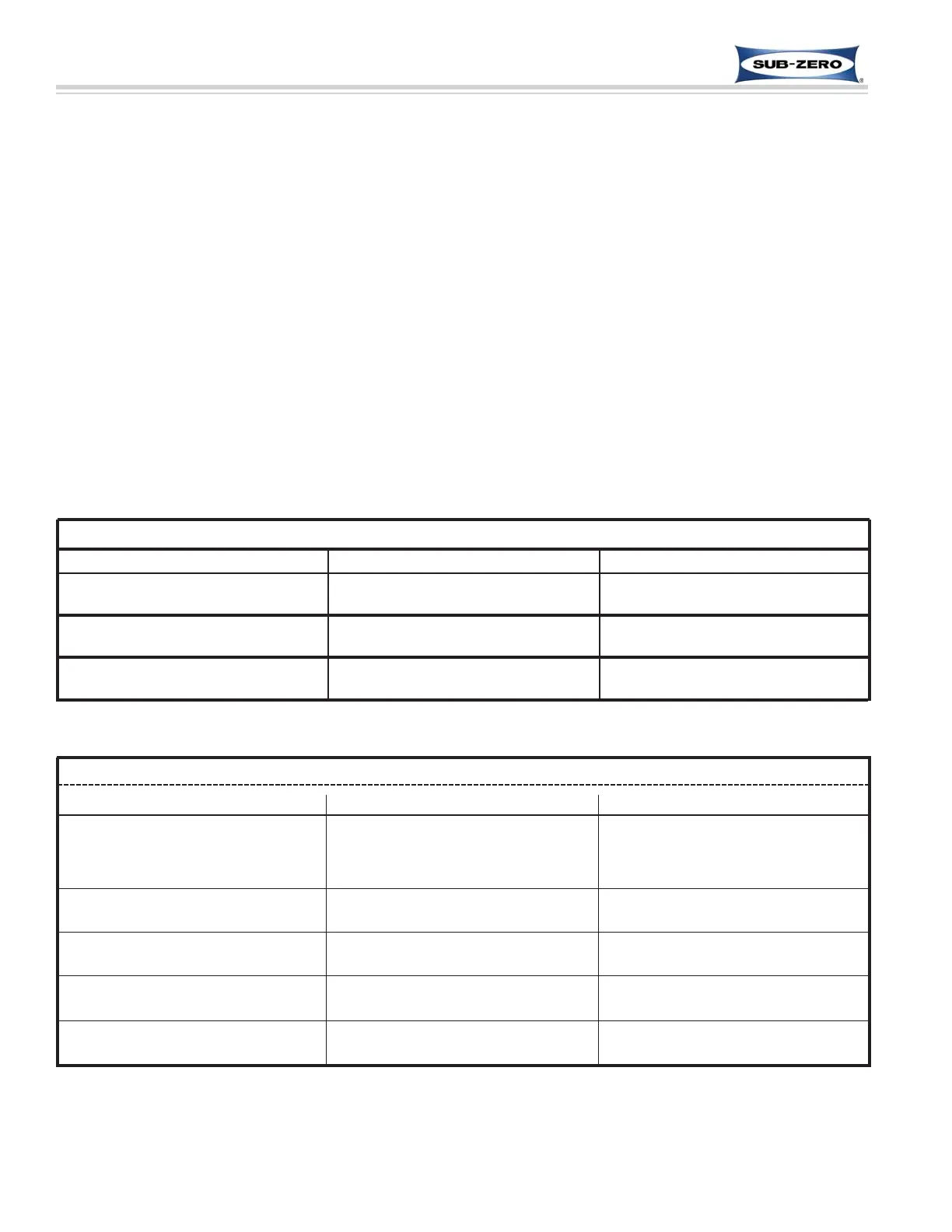

PRESSURE INDICATIONS

If low-side pressure is

NORMAL

LOW

LOW

HIGH

HIGH

& high-side pressure is

NORMAL

LOW

HIGH

LOW

HIGH

possible problem is

MECHANICAL

(see General Troubleshooting Guide)

LEAK

RESTRICTION

INEFFICIENT COMPRESSOR

OVER CHARGE

Model Normal Low-Side Pressures Normal High-Side Pressures

ICB700BC/I

5” Vac - 1 psi to 6 - 12 psi 75 psi to 120 psi

Loading...

Loading...