3 Suburban DynaPack H Series Owner's Manual 10/2017 Rev.4

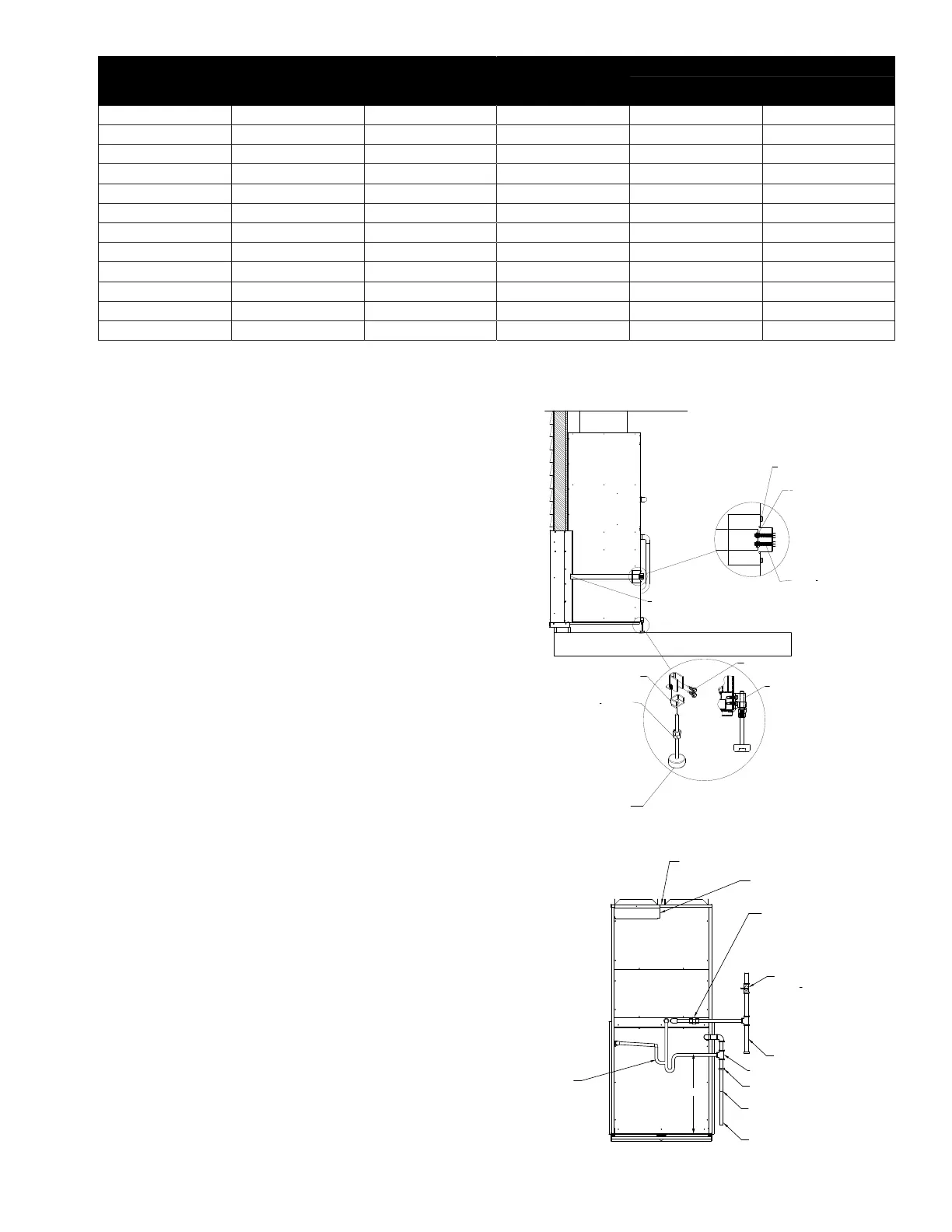

CONDENSATE DRAIN - FURNACE

The high efficiency furnace in this unit will produce condensate when operating.

In addition, a trap is needed in order to overcome the negative pressure produced

by the combustion inducer blower.

1. With the gas valve and outdoor section access panels removed, connect

the drain trap to the internal drain hoses using the 90 degree barb fittings

provided.

2. Install the ¾ x ¾ x 5/8 tee fitting in the air conditioner drain at the level of

the combustion condensate trap.

3. Complete the furnace drain line by installing a barb fitting into the drain

trap hose.

4. Install a 5/8 vinyl hose between the barb sitting and the tee fitting

installed in the air conditioner drain line. See Figure 5. The furnace

condensate line will self-prime on startup.

Note: The furnace drain and air conditioner condensate drain are open to the

atmosphere which gives pressure equalization on the sewer trap preventing

“double trapping.”

ELECTRICAL CONNECTIONS

The Dynapack unit is approved using copper conductors only. See the unit data

plate for unit minimum circuit ampacity. Size the wire based on the unit circuit

ampacity, type of wire used, and method of wiring, in conduit or open. If the

electrical supply is 208 volt, then do not exceed 2% voltage drop based on the

length of wire run. See the National Electrical Code or the Canadian Electrical

Code for more information.

The typical electrical supply is two phase wires where voltage measured is 208-

230 volts phase to phase. An additional wire for unit grounding is required. See

the unit data plate for the maximum fuse or circuit breaker size. It is recommended

that time delay fuses or a two pole HACR breaker be used in order to prevent

nuisance trips.

Alternately, the Dynapack unit may be wired with one phase wire where the

voltage measured is 208-230 volts phase to neutral. In this case, the phase wire

should be connected to L1 on the contactor. An additional wire for unit grounding

is required.

On 208 volt systems the transformer wiring needs to be changed. Swap the red

transformer wire for the orange wire for 208 volt operation.

A disconnect should be installed next to the unit so the electrical power can be

turned off for servicing or maintenance.

GAS SUPPLY

All Dynapack units are built to operate on natural gas.

Minimum gas supply pressure for purposes of input adjustment:

Minimum Maximum

Natural Gas 5" W.C. * 7" W.C.

*Water Column

GAS PIPING

The Dynapack unit has a ½” pipe connection for the gas line. The size of the gas

piping must be based on the length of the run and not the connection size. See

table 5 for reference pipe sizing.

Consult with the local gas utility or code authority for gas piping installation.

If local codes allow the use of a exible gas appliance connector, always use

a new listed connector. Do not use a connector which has previously serviced

another gas appliance.

The gas piping should contain a manual shut off valve with test port near the

furnace in addition to a drip leg and a ground joint union for servicing. The

test port needs to be upstream of the manual shut off valve for leak testing and

adjusting the supply pressure regulator.

The manual shut off valve must be rated for the gas piping test pressure. If not,

then the shut off valve must be removed from the piping system during testing.

Once the gas piping up to the shut off valve has been tested, the remaining piping

to the unit gas valve must be tested. Do not exceed ½ psig or 14” water column

for this test or the gas valve may be damaged.

RETURN SUPPLY

ACCESS PANEL

TO

CONTROLS

ACCESS PANEL

TO GAS VALVE

AND BURNERS

ACCESS PANEL

TO COMPRESSOR

AND OUTDOOR FAN

DRIP LEG (FIELD SUPPLIED)

MANUAL SHUTOFF VALVE

WITH

1

8

"NPT PLUGGED TAPPING,

ACCESSIBLE FOR TEST GAUGE

CONNECTION (FIELD SUPPLIED)

CONDENSATE DRAIN

GROUND JOINT UNION

(FIELD SUPPLIED)

FILTER DOOR

TRAP

ROUTE TO BUILDING DRAIN

ELECTRICAL POWER ENTRANCE

FRONT VIEW

3/4" X 3/4" X 5/8" TEE

DRAIN TRAP TUBE

18"

Figure 5

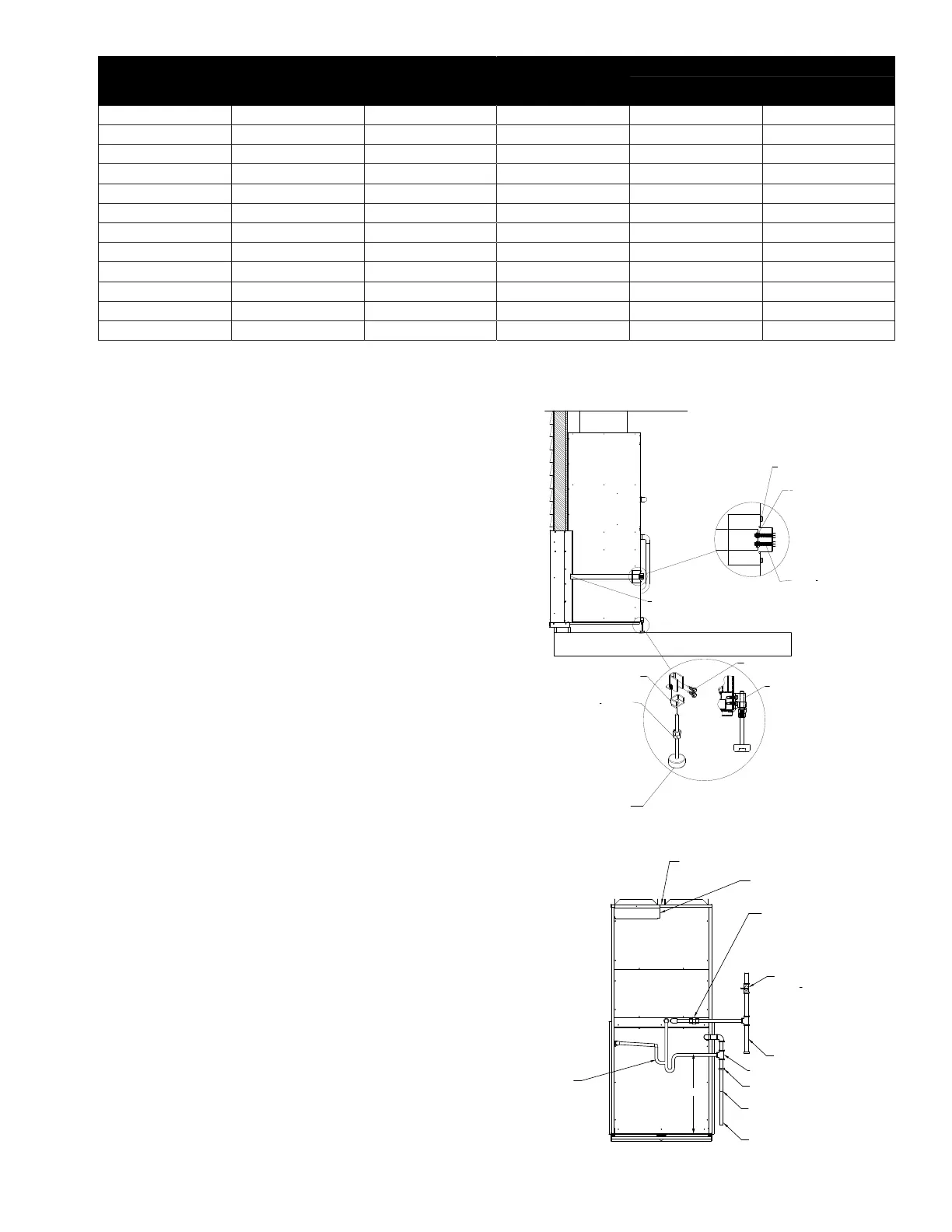

#10-24 X 1

1

2

MACHINE SCREW

3

8

-16 HEX NUT

THE LEVELER BRACKET INSTALLS

INTO UNIT BRACKET AND IS HELD

IN PLACE BY THE UNIT WEIGHT

#12 X .75" DRILL SCREWS

(2 PLACES)

LOCATE BRACKET BY INSTALLING

THE TAB UNDER THE UNIT BASE

AND ABOVE THE BASE RAIL.

TINNERMAN CLIP

ATTACH BRACKET TO UNIT

WITH (2) #10 X 1/2" DRILL SCREWS

(2 ON EACH BRACKET)

ENGAGE FLANGE ON WALL SLEEVE

WITH FLANGE ON STRAP. TIGHTEN

MACHINE SCREWS UNTIL BRACKET

CAN BE SECURED TO UNIT WITH

DRILL SCREWS.

Figure 4

WALL SLEEVE

(Nominal)

MAX WALL

THICKNESS

PVC PIPE CUT

LENGTH (Inches)

PIPE LENGTH

EXTENSION FROM

UNIT

WALL SLEEVE STOCK NUMBERS

SHORT LONG

*CW 3 7/8" 27" 6" ---------- ----------

4" 5 7/8" 29" 8" 1741 1736

6" 7 7/8" 31" 10" 1742 1737

8" 9 7/8" 33" 12" 1743 1738

10" 11 7/8" 35" 14" 1744 1739

12" 13 7/8" 37" 16" 1745 1740

14" 15 7/8" 39" 18" 1769 1770

16" 17 7/8" 41" 20" 1771 1772

17" 18 7/8" 42" 21" 1773 1774

18" 19 7/8" 43" 22" ---------- ----------

20" 21 7/8" 45" 24" ---------- ----------

22" 23 7/8" 47" 26" ---------- ----------

TABLE 1

Loading...

Loading...