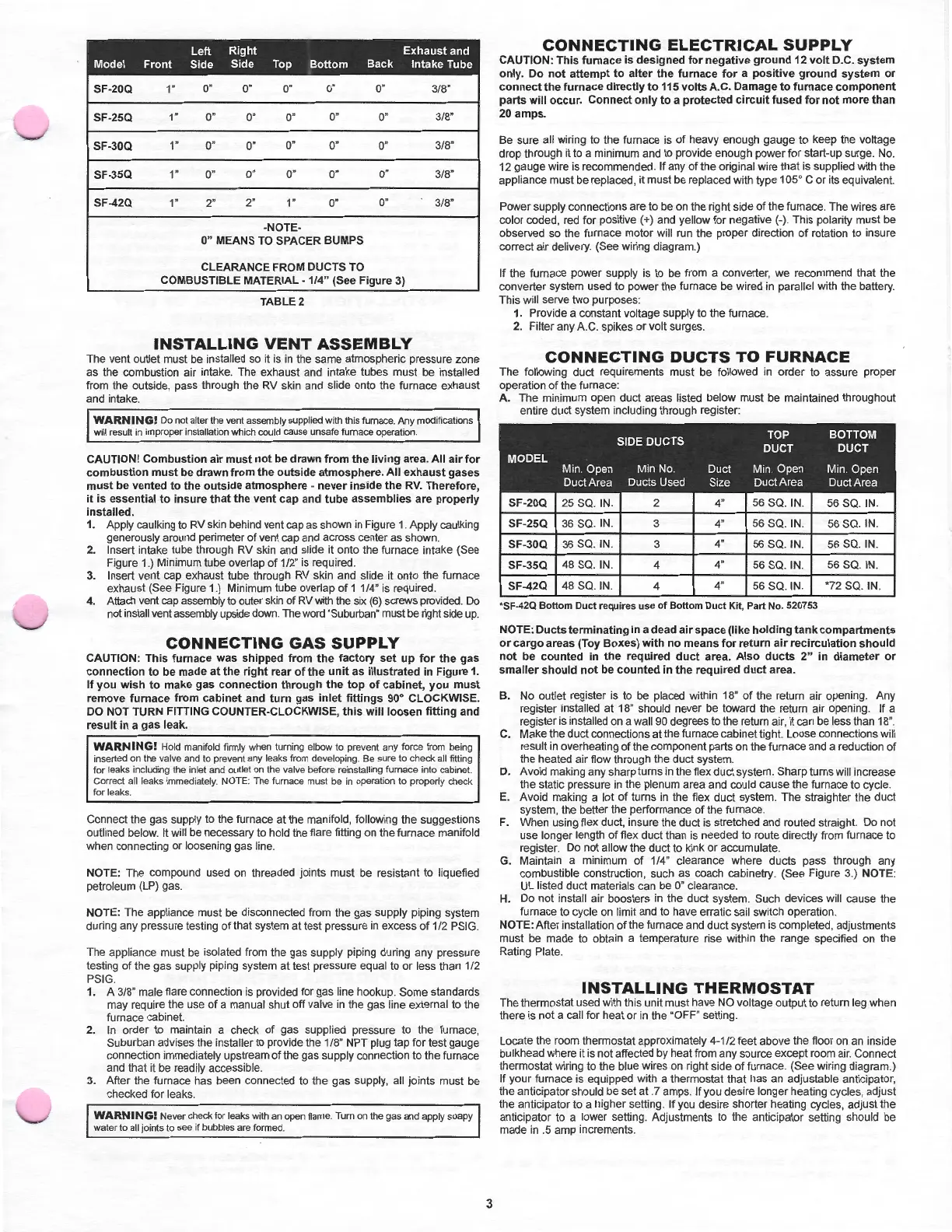

Left

Right

Exhaust

and

Model

Front

Side Side

Top

Bottom

Back

Intake

Tube

SF-20Q 1"

O" O" O" O"

O"

3/8"

SF-25Q

1"

O" O" O" O"

O"

3/8"

SF-30Q

1"

O"

O" O" O" O"

3/8"

SF-35Q

1"

O"

O" O" O" O"

3/8"

SF-42Q

1"

2"

2" 1"

O"

O"

3/8"

-NOTE-

O"

MEANS

TO SPACER

BUMPS

CLEARANCE

FROM

D

UCTS

TO

COMBUSTIBLE

MATERIAL

- 1

/4"

(See

Figure

3)

TABLE

2

INSTALLING

VENT

ASSEMBLY

The

vent outlet must be installed so it is

in

the

same

atmospheric pressure zone

as the combustion air intake. The exhaust and intake tubes

must

be installed

from the outside, pass through the RV skin and slide onto the furnace exhaust

and intake.

WARNING!

Do not alter the vent assembly supplied with this furnace. Any modifications

will result

in

improper installation which could

ca

u

se

unsafe furnace operation.

CAUTION!

Combustion

air

must

not

be

dra

wn

from

the

living

area.

All

air

for

combustion

must

be

drawn

from

the

outsid

e

atmosphere.

All

exhaust

gases

must

be

vented

to

the

outs

ide

atmosphere

-

never

inside

the

RV.

Therefore,

it

is

essential

to

insure

that

the

vent

cap

and

tube

assemblies

are

properly

installed.

1. Apply caulking to RV skin behind vent cap as shown

in

Figure 1. Apply caulking

generously around perimeter

of

vent cap and across center as shown.

2. Insert intake tube through RV skin and

sl

ide it onto the furnace intake (See

Figure 1.) Minimum tube overlap

of

1/2"

is

required.

3.

Insert vent cap exhaust tube through RV skin and slide it onto the furnace

exhaust (See Figure 1.) Minimum tube overlap

of

1 1/4" is required.

4. Attach vent cap assembly to outer skin of RV with the six

(6)

screws provided. Do

not install vent assembly upside down. The wo

rd

"Suburban" must be right side up.

CONNECTING

GAS

SUPPLY

CAUTION:

This

furnace

was

shipped

from

the

factory

set

up

for

the

gas

connection

to

be

made

at

the

right

rear

of

the

unit

as

illustrated

in Figure

1.

If

you

wish

to

make

gas

connection

throu

gh

the

top

of

cabinet,

you

must

remove

furnace

from

cabinet

and

turn

gas

inlet

fittings

90°

CLOCKWISE.

DO NOT TURN FITTING COUNTER-CLOCKWISE,

this

will

loosen

fitting

and

result

in

a

gas

leak.

WARNING!

Hold manifo

ld

firmly when tu

rn

in

g elbow to prevent any force from being

inserted on the

valve and to

pre

vent any leaks from developi

ng.

Be

sure to check all fitting

for leaks includi

ng

the inlet a

nd

outlet on the valve befo

re

reinstalling furnace into cabinet.

Correct a

ll

leaks immedi

at

e

ly.

NOTE: The furnace must be in operation to properly check

for

leaks.

Connect the gas supply to the furnace

at

the manifold, following the suggestions

outlined below. It will be necessary to hold the flare fitting

on

the furnace manifold

when connecting or loosening gas line.

NOTE: The compound used

on

threaded joints must be resistant to liquefied

petroleum (LP) gas.

NOTE: The appliance must be disconnected fr

om

the gas supply piping system

during any pressure t

est

ing

of

that system

at

te

st pressure in excess

of

1 /2 PSIG.

The appliance must be isolated from the gas supply piping during any pressure

testing

of

the gas supply piping system

at

test pressure equal to or less than 1/2

PSIG.

1. A 3/8" male flare connection is provided for gas line hookup.

Some

standards

may require the use

of

a manual shut

off

valve

in

the gas line external to the

furnace cabinet.

2.

In

order to maintain a check

of

gas supplied pressure to the furnace,

Suburban advises the installer to provide the 1/8" NPT plug tap for test gauge

connection immediately upstream

of

the gas supply connection to

the

furnace

and that it be readily accessible.

3.

After the furnace has been connected to t

he

gas supply, all

joints

must be

checked for leaks.

WARNING!

Never check for leaks wi

th

an open

fl

ame. Turn on the gas and apply soapy

water to

all joints to see if bubbles are formed.

3

CONNECTING

ELECTRICAL

SUPPLY

CAUTION:

Th

is

furnace

is

designed

for

negative

ground

12

volt

D.C.

system

only

.

Do

not

attempt

to

alter

the

furnace

for

a

positive

ground

system

or

connect

the

furnace

directly

to

115

volts

A.C

.

Damage

to

furnace

component

parts

will

occur.

Connect

only

to

a

protected

circuit

fused

for

not

more

than

20

amps.

Be

sure all wiring to the furnace is

of

heavy enough

gauge

to keep the voltage

drop through it to a minimum and to provide enough

power

for start-up surge. No.

12 gauge wire is recommended. If any

of

the

original wire that is supplied with the

appliance must be replaced, it must be replaced with type 105° C

or

its equivalent.

Power

supply connections are to be on the right side

of

the

furnace.

The

wires are

color coded, red for positive (+) and yellow for negative (-

).

This polarity

must

be

observed so the furnace motor will run the proper direction

of

rotation to insure

correct air delivery. (See wiring diagram.)

If the furnace power supply is to be from a converter,

we

recommend that the

converter system used to power the furnace be wired

in

parallel with the battery.

This will serve two purposes:

1. Provide a constant voltage supply to the furnace.

2. Filter any A.G. spikes

or

volt surges.

CONNECTING

DUCTS

TO

FURNACE

The

following duct requirements

must

be followed

in

order

to assure proper

operation

of

the furnace:

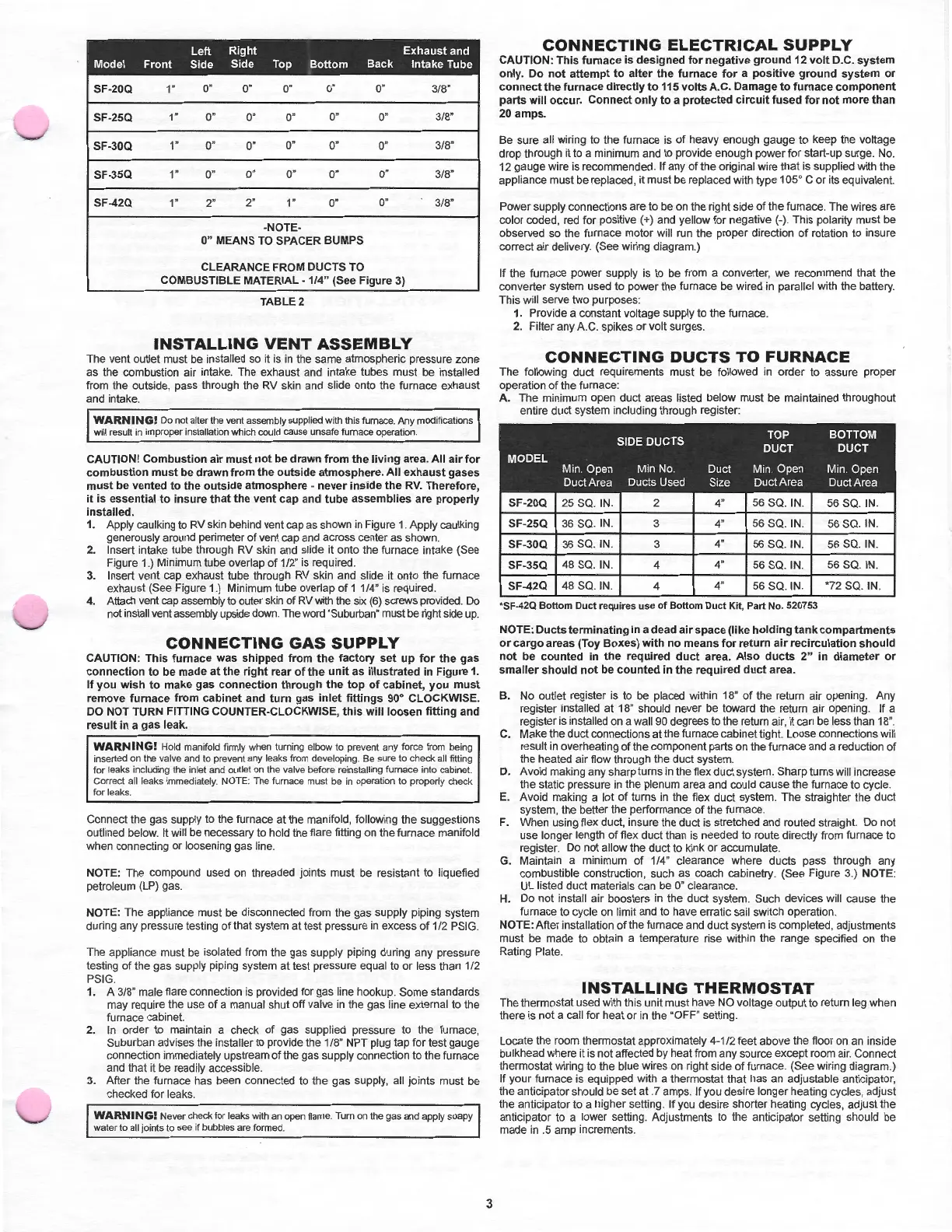

A.

The

minimum open duct areas listed below must be maintained throughout

entire duct system including

through register:

SIDE DUCTS

TOP

BOTTOM

DUCT

DUCT

MODEL

Min Open Min No

Duct

Min Open Min Open

Duct Area Ducts Used Size Duct

Area

Duct Area

SF-20Q 25 SQ.

IN

. 2 4" 56 SQ. IN. 56 SQ.

IN

.

SF-25Q 36 SQ.

IN

. 3 4" 56 SQ.

IN

. 56 SQ.

IN

.

SF-30Q

36 SQ.

IN

.

3

4" 56

SQ

.

IN

.

56 SQ.

IN

.

SF-35Q

48 SQ. IN.

4

4" 56 SQ.

IN.

56 SQ.

IN

.

SF-42Q 48 SQ.

IN

. 4 4" 56 SQ. IN. *72 SQ. IN.

•SF-420

Bottom

Duct

requires

use

of

Bottom

Duct

Kit

, Part No. 520753

NOTE:

Ducts

terminating

in

a

dead

airspace

(like

holding

tank

compartments

or

cargo

areas

(Toy

Boxes)

with

no

means

for

return

air

recirculation

should

not

be

counted

in

the

required

duct

area.

Also

ducts

2"

in

diameter

or

smaller

should

not

be

counted

in

the

required

duct

area.

B. No outlet register is to be placed within 18"

of

the return air opening. Any

register installed at 18" should never be toward the return air opening. If a

register is installed on a wall 90 degrees to the return air, it can be less than 18

".

C.

Make

the

duct connections at the furnace cabinet tight. Loose connections will

result in overheating

of

the component parts on the furnace and a reduction

of

the heated air flow through the duct system.

D.

Avoid making any sharp turns in the flex duct system. Sharp turns will increase

the

static pressure in the plenum area and could cause the furnace to cycle.

E. Avoid ma

ki

ng a lot

of

turns in the flex

duct

system.

The

straighter the

duc

t

system, the better the performance

of

the furnace.

F.

When using flex duct, insure the duct is stretched and routed straight. Do not

use longer length

of

flex duct than is needed to route directly from furnace to

register. Do not allow the duct to kink or accumulate.

G.

Maintain a minimum

of

1/4" clearance where ducts pass through any

combustible construction, such

as

coach cabinetry. (See Figure 3.) NOTE:

UL listed duct materials can be O" clearance.

H.

Do

not

install

air

boosters in the duct system. Such devices will cause the

furnace to cycle on limit and to have erratic sail switch operation.

NOTE:

After

installation

of

the furnace and duct system is completed, adjustments

must be

made

to obtain a temperature rise within the range specified on the

Rating Plate.

INSTALLING

THERMOSTAT

The thermostat used with this unit

must

have NO voltage output to return leg when

there is

not

a call for heat or

in

the "OFF" setting.

Locate the room thermostat approximately

4-1

/2 feet above the floor on an inside

bulkhead where it is not affected by heat from any source ex

cept

room air. Connect

thermostat wiring to the blue wires on right side

of

furnace. (

See

wiring diagram.)

If

your

furnace is equipped with a thermostat that has an adjustable anticipator,

the anticipator should be set

at

. 7 amps. If you desire longer heating cycles, adjust

the anticipator to a higher setting. If you desire shorter heating cycles, adjust the

anticipator to a lower setting. Adjustments to the anticipator setting should be

made

in

.5 amp increments.

Loading...

Loading...