In the U.S.A., the installation of the furnace must be in accordance with local

codes and regulations. In the absence of local codes and regulations, refer to the

latest edition of:

1. Standard for Recreational Vehicles NFPA 1192.

2. National Fuel Gas Code ANSI Z223.1/NFPA 54.

3. Furnace must be electrically grounded in accordance with the latest edition of

the National Electrical Code NFPA 70.

In Canada, the furnace must be installed in accordance with:

1. Standard CSA Z240.0.2-08 Recreational Vehicles.

2. CSA Standard Z240.6.2-08 C22.2 NO.148-08 Electrical Requirements for

Recreational Vehicles.

3. Standard Z240.4.2-08 Installation Requirements for Propane Appliances and

Equipment in Recreational Vehicles.

4. CAN/CGA-B149 Installation Codes.

5. Any applicable local codes and regulations.

This unit is equipped with an electric igniter device that has an energy consumption

of .1 amp @ 12 volts D.C.

RETURN AIR

There are two (2) methods described below for installing the furnace. Regardless

of the method you choose, we require that a permanent opening be provided in

the interior cabinetry of the coach directly in front of the furnace. The opening must

allow for free, unobstructed removal of the furnace. This opening may be used as

a means of providing circulating return air to the furnace. Other openings may be

used as well.

It is important that adequate return air be provided to assure normal heating and

operation of the furnace. Failure to provide the minimum return air will cause

erratic furnace cycling. Refer to the chart shown below for minimum return air

requirements.

NOTE: Return air must be from within the living area of the coach.

NOTE: RV’s that have a wall of separation to a cargo area (Toy Box) to transport

internal combustion engine vehicles must not have return air openings from this

area.

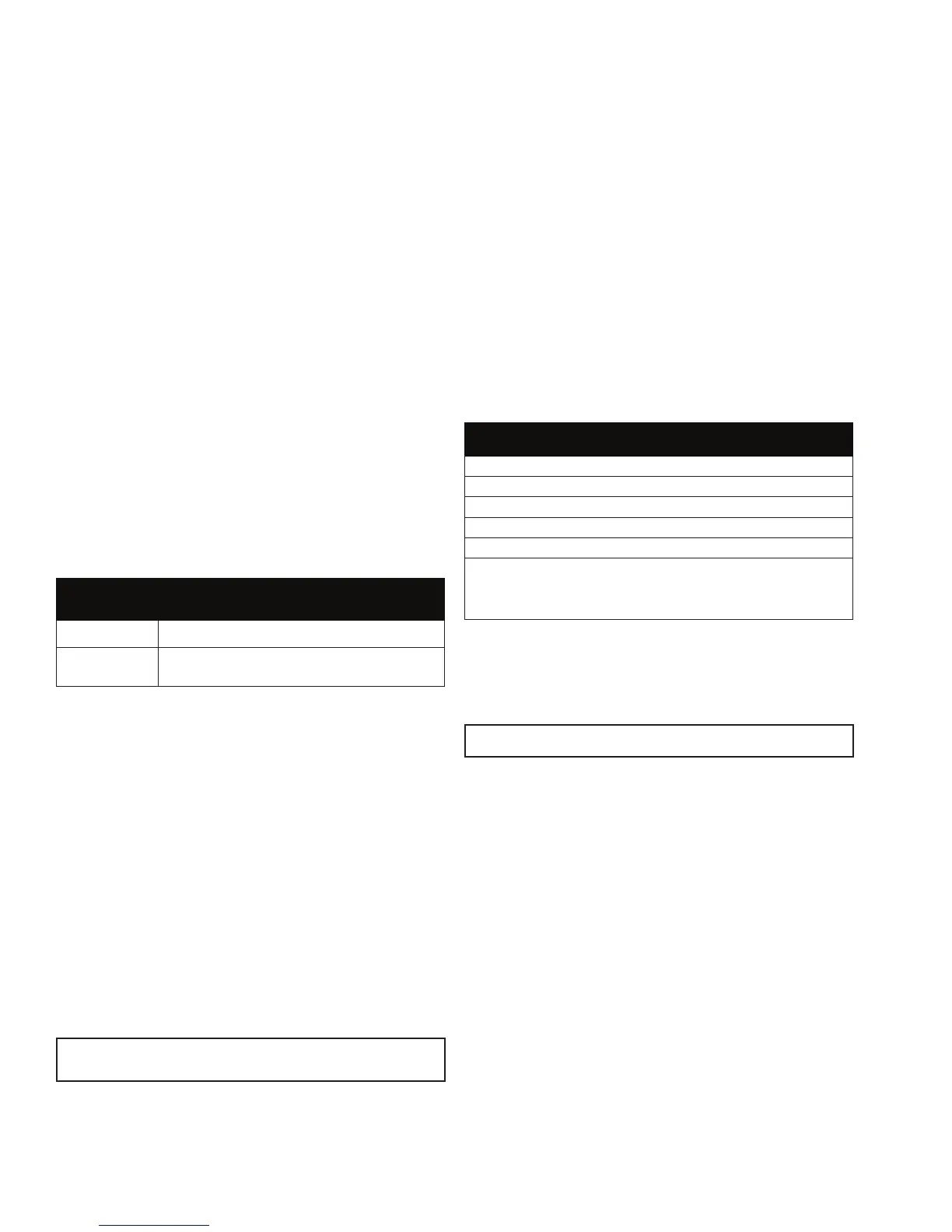

Return Air Requirements

Model Minimum Free (unobstructed) Area

SF-20/25/30/35FQ 55 Sq. In.

SF-42FQ

142 Sq. In.*

*may be reduced to 88 sq. in. min. if 5 ducts are used.

TABLE 1

INSTALLING THE FURNACE

NOTE: Before installing the furnace “X” dimension as illustrated in Figure 2 must

be determined.

1. Locate the furnace near lengthwise center of the coach.

2. Choose a location for installation out of the way of wires, pipes, etc., which

might interfere with the installation. Adhere to the minimum clearances from

the cabinet to combustible construction as listed in Table 2. Refer to Figure 3

for illustration of furnace clearances.

NOTE: Side and top clearances may be “0” for through the wall installations up to

a maximum of 3” wall thickness. (See Figure 1.)

3. When an appliance is installed directly on carpeting, tile or other combustible

material, other than wood ooring, the appliance shall be installed on a metal

or wood panel extending the full width and depth of the appliance. If preferred,

the carpeting, tile or combustible materials, other than wood may be cut

away the full length and depth of the appliance plus the appliance minimum

clearances to combustibles. (See Table 2.)

4. Determine “x” dimension as shown in Figure 2. The tubes supplied with the

furnace will accommodate an installation range for “x” from 1-1/2” - 3” If “x”

dimension is less than 1-1/2” or greater than 3”, then special vent tubes as

charted in Figure 2 must be ordered.

WARNING! Do not alter, cut or otherwise modify the vent tubes as supplied by Suburban.

Doing so could result in inadequate intake of combustion air or improper venting of furnace

exhaust.

5. After determining “x” dimension, complete the furnace installation as follows:

A. IF INSTALLED DIRECTLY AGAINST OUTER SKIN OR “X” DIMENSION IS

0 - 1-1/2”

1. Vent Kit 520767 must be ordered. Do not cut or alter the vent tubes supplied

with the furnace.

2. Cut an opening through the inner wall 17-3/4 x 8”. This will allow the rear of

the furnace to be installed against the outer skin of the coach. (See Figure 1.)

3. Cut two 2-1/4” diameter holes through the outer skin of the coach, as shown

in Figure 1.

4. Put furnace in place, making sure that rear of furnace cabinet is as close to

outer skin of coach as possible and still assure proper vent tube overlap. (See

Installing Vent Assembly.) Secure furnace to cabinet. (See Figure 1.)

5. Secure furnace to the oor using two (2) hole provided in the furnace cabinet.

(See Figure 1.)

6. Install vent assembly. (See instructions for installing vent.)

B. IF NOT INSTALLED AGAINST OUTER SKIN AND “X” DIMENSION

GREATER THAN 1-1/2”

1. Determine “x” dimension as illustrated in Figure 2. Tube length for “x”

dimension are charted. Special tubes, if needed, must be ordered.

2. Locate center lines for exhaust and intake tubes as shown Figure 1. Cut two

2-3/4” diameter holes through coach wall for exhaust and intake. (See Figure 2.)

3. Put furnace in place and secure furnace to cabinet.

4. Secure furnace to the oor using the two (2) holes provided in the furnace

cabinet. (See Figure 1,)

5. Install vent assembly. (See instructions for Installing Vent.)

6. Reinstall cabinet front.

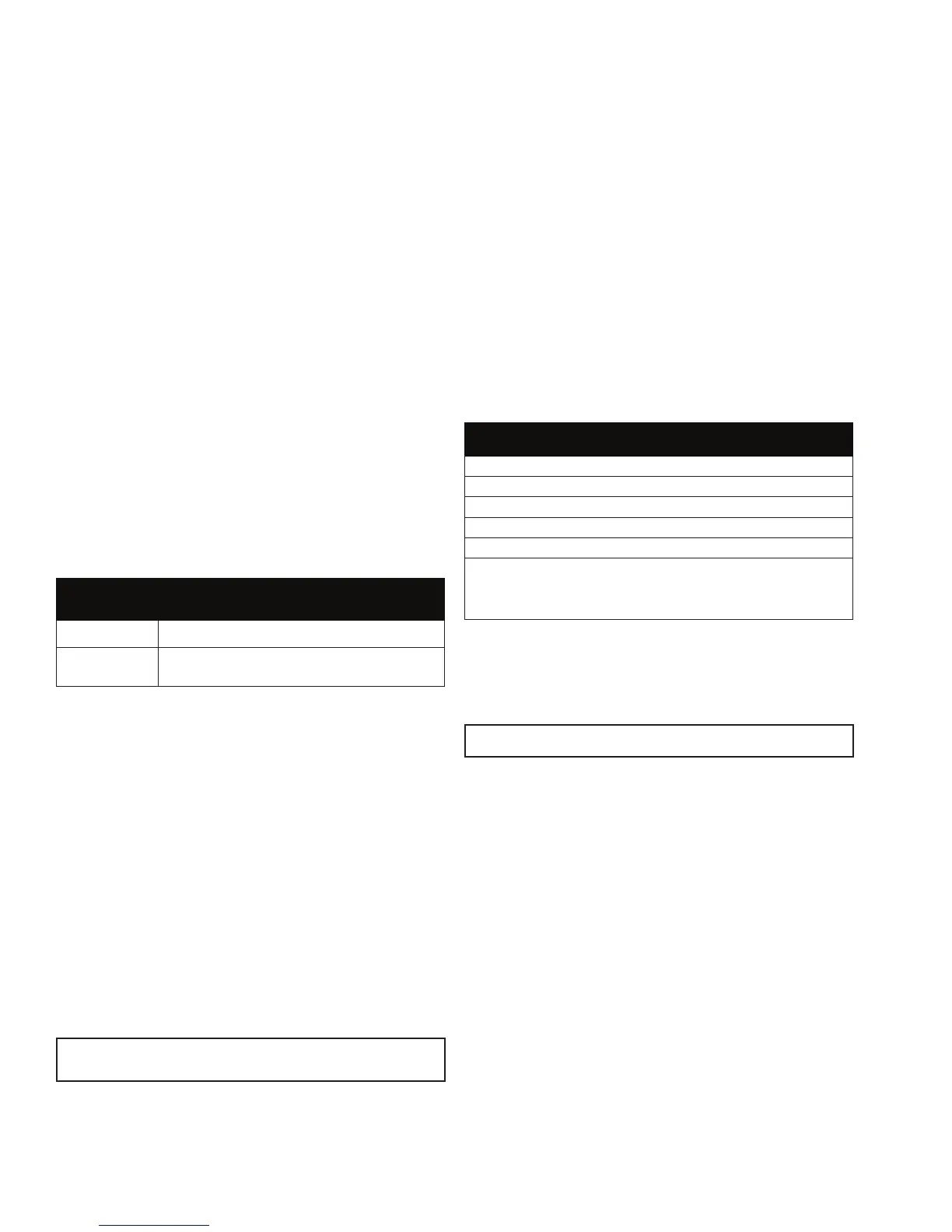

Left Right Exhaust and

Model Front Side Side Top Bottom Back Intake Tube

SF-20FQ 1” 0” 0” 0” 0” 0” 3/8”

SF-25FQ 1” 0” 0” 0” 0” 0” 3/8”

SF-30FQ 1” 0” 0” 0” 0” 0” 3/8”

SF-35FQ 1” 0” 0” 0” 0” 0” 3/8”

SF-42FQ 1” 2” 2” 1” 0” 0” 3/8”

-NOTE-

0” MEANS TO SPACER BUMPS

CLEARANCE FROM DUCTS TO

COMBUSTIBLE MATERIAL - 1/4” (See Figure 3)

TABLE 2

INSTALLING VENT ASSEMBLY

The vent outlet must be installed so it is in the same atmospheric pressure zone

as the combustion air intake. The exhaust and intake tubes must be installed

from the outside, pass through the RV skin and slide onto the furnace exhaust

and intake.

WARNING! Do not alter the vent assembly supplied with this furnace. Any modications

will result in improper installation which could cause unsafe furnace operation.

CAUTION! Combustion air must not be drawn from the living area. All air for

combustion must be drawn from the outside atmosphere. All exhaust gases

must be vented to the outside atmosphere - never inside the RV. Therefore, it is

essential to insure that the vent cap and tube assemblies are properly installed.

1. Apply caulking to RV skin behind vent cap as shown in Figure 1. Apply

caulking generously around perimeter of vent cap and across center as

shown.

2. Insert intake tube through RV skin and slide it onto the furnace intake (See

Figure 2.) Minimum tube overlap of 1/2” is required.

3. Insert vent cap exhaust tube through RV skin and slide it onto the furnace

exhaust (See Figure 2.) Minimum tube overlap of 1 1/4” is required.

4. Attach vent cap assembly to outer skin of RV with the six (6) screws provided.

Do not install vent assembly upside down. The word “Suburban” must be right

side up.

CONNECTING GAS SUPPLY

Connect the gas supply to the furnace at the manifold, following the suggestions

outlined below. It will be necessary to hold the are tting on the furnace manifold

when connecting or loosening gas line.

NOTE: The compound used on threaded joints must be resistant to liqueed

petroleum (LP) gas.

NOTE: The appliance must be disconnected from the gas supply piping system

during any pressure testing of that system at test pressure in excess of 1/2 PSIG.

2

Loading...

Loading...