SUNERGY USA WORKS LLC

between the module frame and support structure to prevent this type of corrosion. Module

support structures that are to be used to support modules at correct tilt angles should be

wind and snow load rated for use by the appropriate local and civil codes prior to

installation.

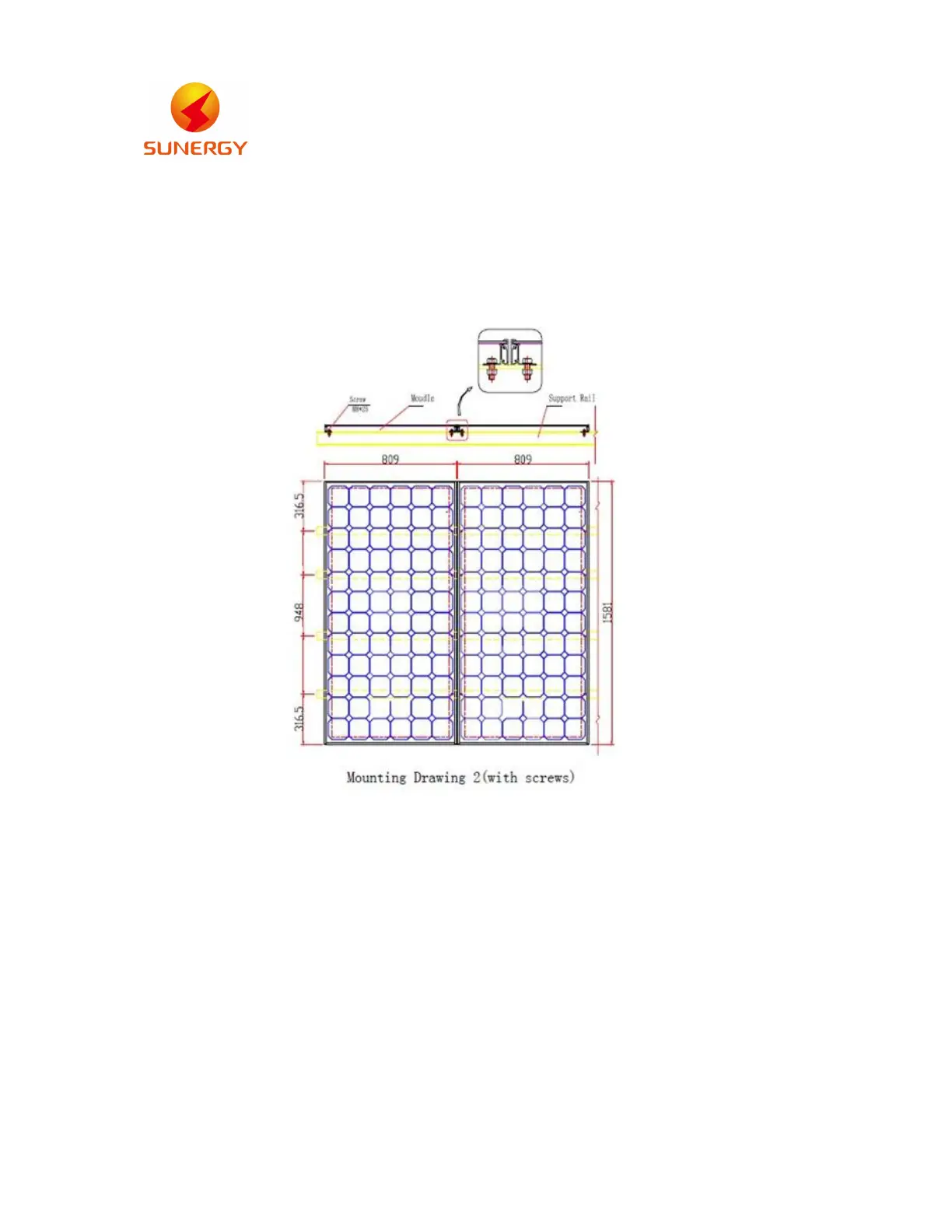

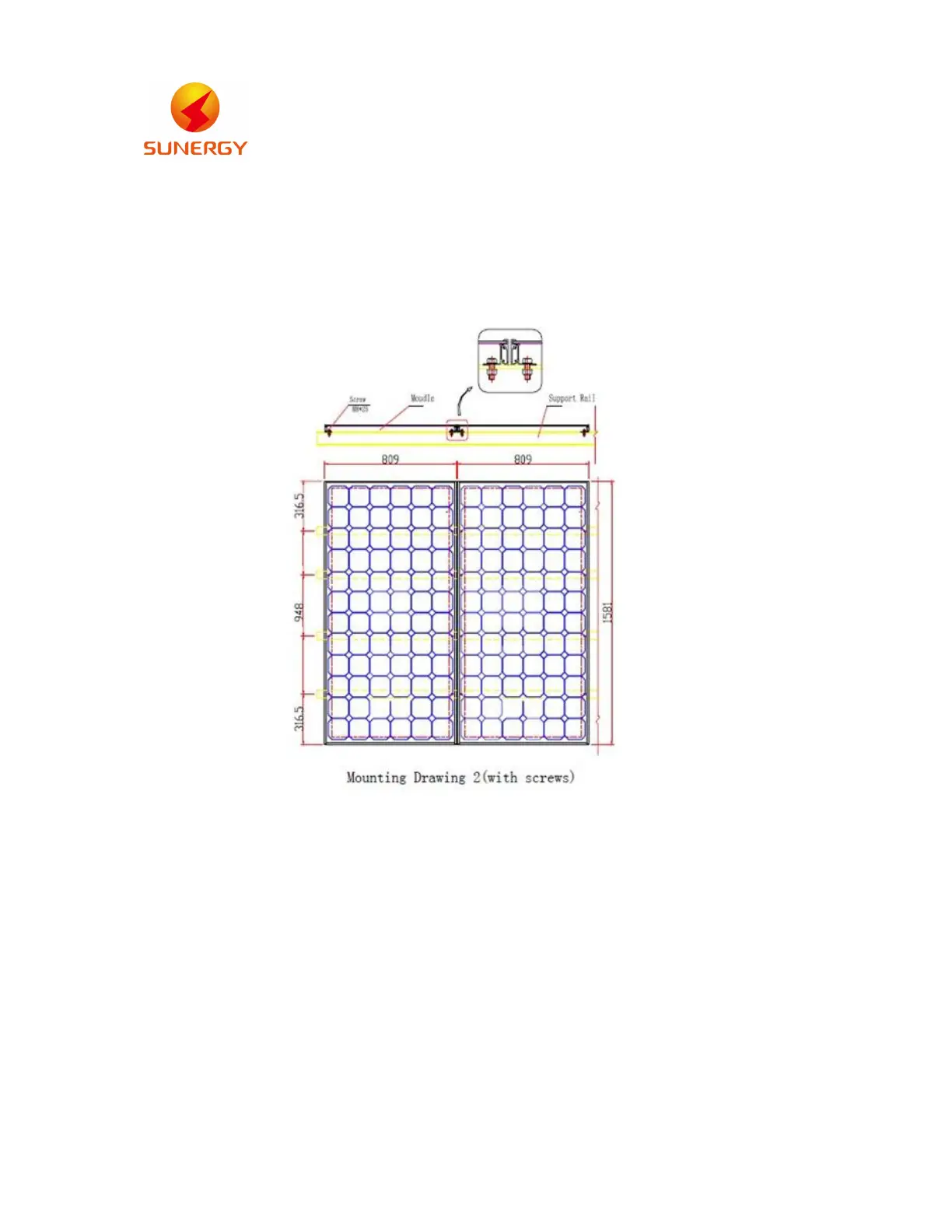

SUNERGY modules can be mounted as following method:

Using corrosion-proof screws (M8) on the existing installing holes in the module frame.

The frame of each module has 8 mounting holes (12mm*9mm) used to secure the modules

to supporting structure. The module frame must be attached to a supporting structure using

M8 stainless steel hardware together with spring washers and flat washers in eight places

symmetrical on the SUNERGY module. The applied torque is about 8 Newton-meters.

The module can’t be installed using clamps.

It is not permitted to modify the module frame under any circumstances. Recommended

distance between 2 solar modules is 5mm considering linear thermal expansion of the

module frames. Clearance between the module frame and mounting surface may be

required to prevent the junction box from touching the surface, and to circulate cooling air

around the back of the module.

10. GROUNDING

All module frames and mounting racks must be properly grounded in accordance with the

appropriate respective national electrical code. Proper grounding is achieved by connecting the

module frame(s) and structural members contiguously one to another using a suitable grounding

Loading...

Loading...