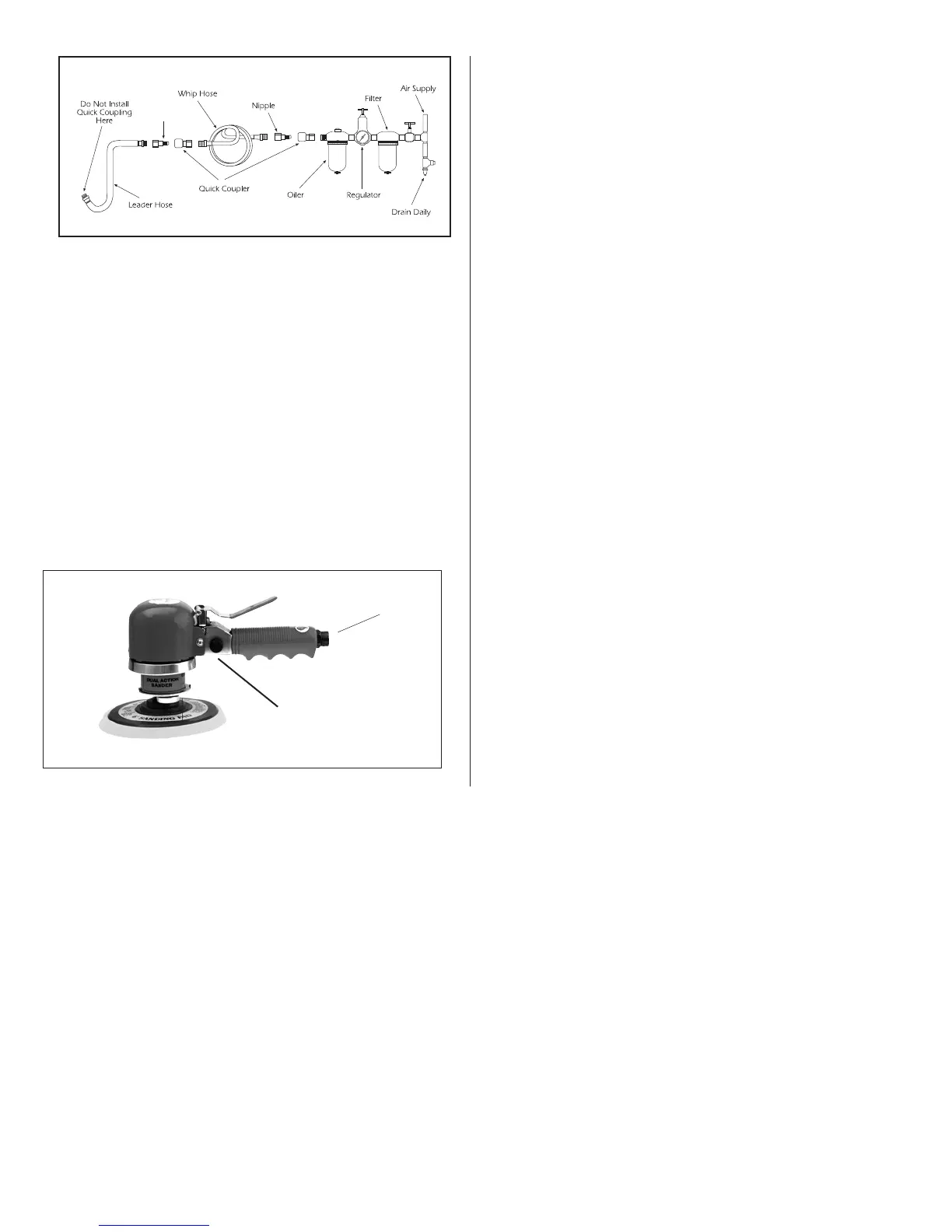

Air Supply...

Tools of this class operate on a wide range of air pressures. It is

recommended that air pressure of these tools measure 90 PSI at the

tool while running free. Higher pressure and unclean air will

shorten the tool’s life because of faster wear and may create a

hazardous condition.

Water in the air line will cause damage to the tool. Drain the air

tank daily. Clean the air inlet filter screen on at least a weekly

schedule. The recommended hookup procedure can be viewed in

Figure 1.

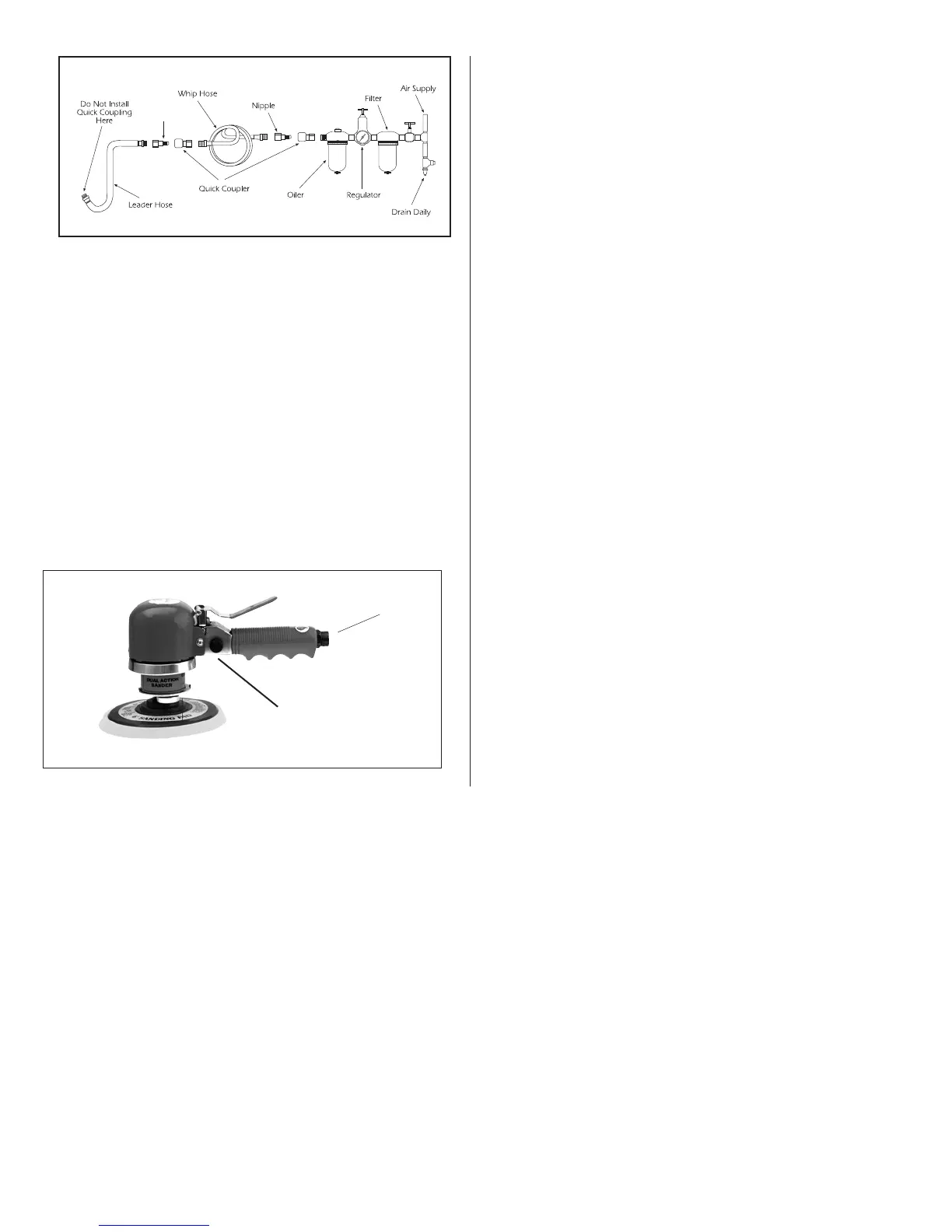

The air inlet (B) Figure 2, used for connecting air supply, has

standard 1/4" NPT American Thread.

Line pressure should be increased to compensate for unusually long

air hoses (over 25 feet). Minimum hose diameter should be 1/4"

I.D. and fittings should have the same inside dimensions.

(B) Air Inlet

Lubrication...

Lubricate the tool daily with a good grade of air tool oil. If no air

line oiler is used, run a teaspoon of oil through the tool. The oil can

be squirted into the tool air inlet (B) Figure 2, or into the hose at the

nearest connection to the air supply, then run the tool. A rust

inhibitive oil is acceptable for air tools.

WARNING: After an air tool has been lubricated, oil will discharge

through the exhaust port during the first few seconds of operation.

The exhaust port must be covered with a towel before applying air

pressure to prevent serious injury.

Troubleshooting...

Other factors outside the tool may cause loss of power or erratic

action. Reduced compressor output, excessive drain on the air line,

moisture or restrictions in air pipes or the use of hose connections of

improper size or poor condition may reduce air supply. Grit or gum

deposits in the tool may cut power and may be corrected by

cleaning the air strainer and flushing out the tool with gum solvent

oil or an equal mixture of SAE #10 oil and kerosene. If outside

conditions are in order, disconnect tool from hose, and take tool to

your nearest authorized service center.

Operation...

The air regulator knob can be used as an air throttle and can be

used for setting positive speed control. The air inlet used for

connecting air supply has standard 1/4" NPT thread.

Let the sander do the work. The normal weight of the machine is

sufficient for efficient sanding. Do not put additional pressure on the

machine. This will only slow down the speed of the pad, reduce

sanding efficiency and put an additional burden on the motor. Start

the sander off the work, set it down on the work evenly and move it

slowly back and forth in wide, overlapping areas. When finished

sanding, lift it off the work before stopping the motor.

(A) Air Regulator Valve

Nipple

Figure 1

Figure 2

Discover various power tools in our online store.

Loading...

Loading...