Use only an AC power supply and always ground the

machine before use. If you use an extension cord, it

must be as short as possible and of suffi cient capacity

Input voltage should not vary by more than 10% of

the specifi ed rating. Always check the voltage before

operating the machine. An incorrect voltage could

seriously damage the motor.

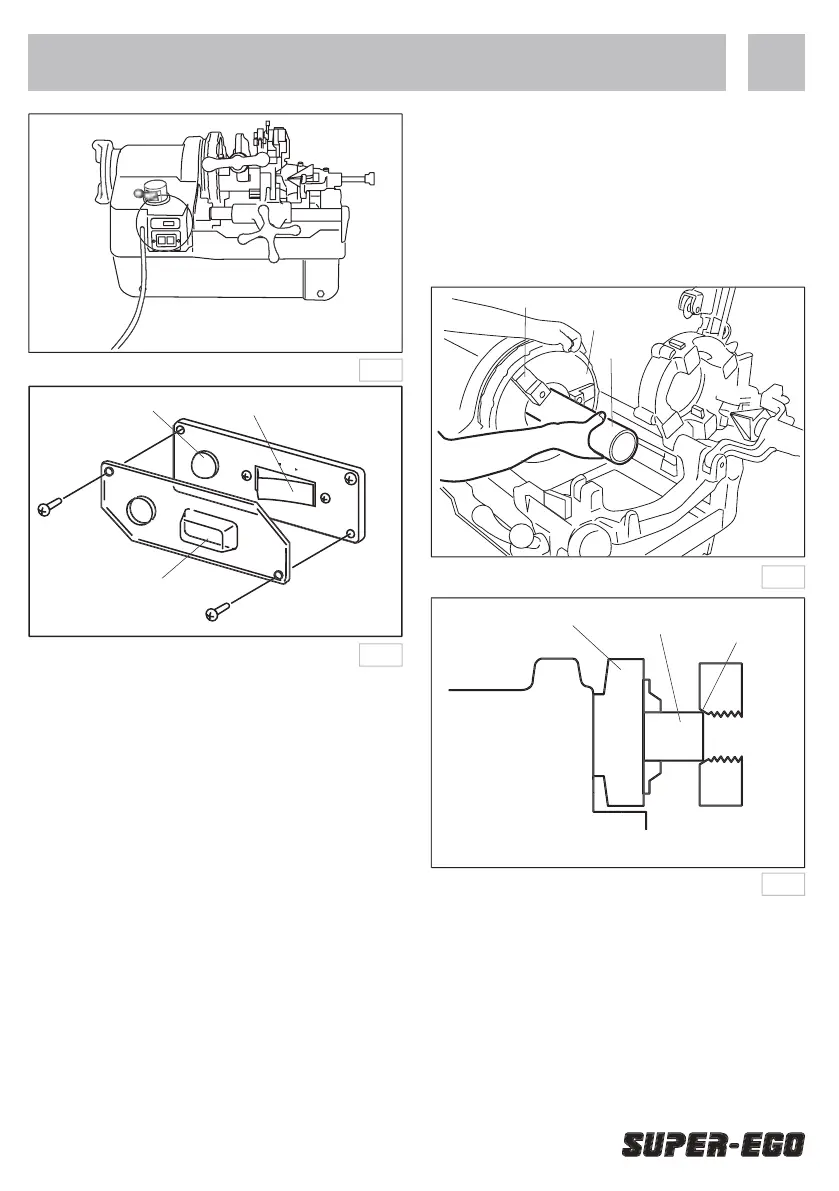

Setting the pipe in position

1. Open both chucks wider than the size of pipe you

are going to cut and insert the pipe from the rear

chuck end wherever possible.

2. Close the rear chuck and, holding the pipe in your

right hand, close the hammer chuck to fi x the pipe

in position. Jerk the hand-wheel sharply towards

3. When you have fi nished cutting, a sharp jerk in the

opposite direction will release the pipe.

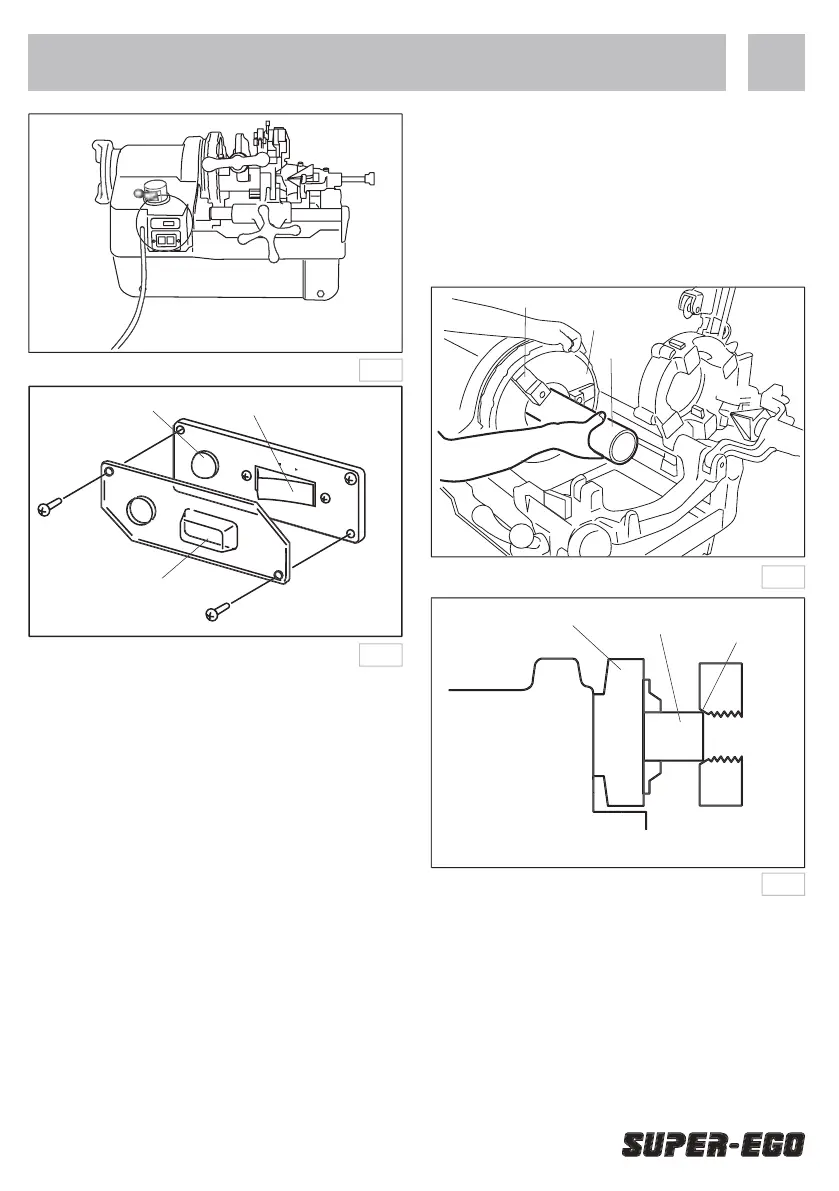

Tips for working with short pipes

When working with short pipes that do not extend as

far as the rear chuck, loosen the hammer chuck a little

and move the pipe so that it comes into contact with

the dies as shown in the diagram opposite. This will

help to centre the pipe when you tighten the hammer

chuck. In this way a smooth taper cut will be ensured

When threading 1/2 - 2” pipes, use the Uni auto V

die head. The Uni auto V also allows you to adjust

threading length. Push the cam plate up and set the

auto-open pin in position. As the dies travel along the

pipe, the end of the pipe comes into contact with the

pin and pushes it out of its groove, thereby releasing

Loading...

Loading...