Operating guidelines / Maintenance

GB

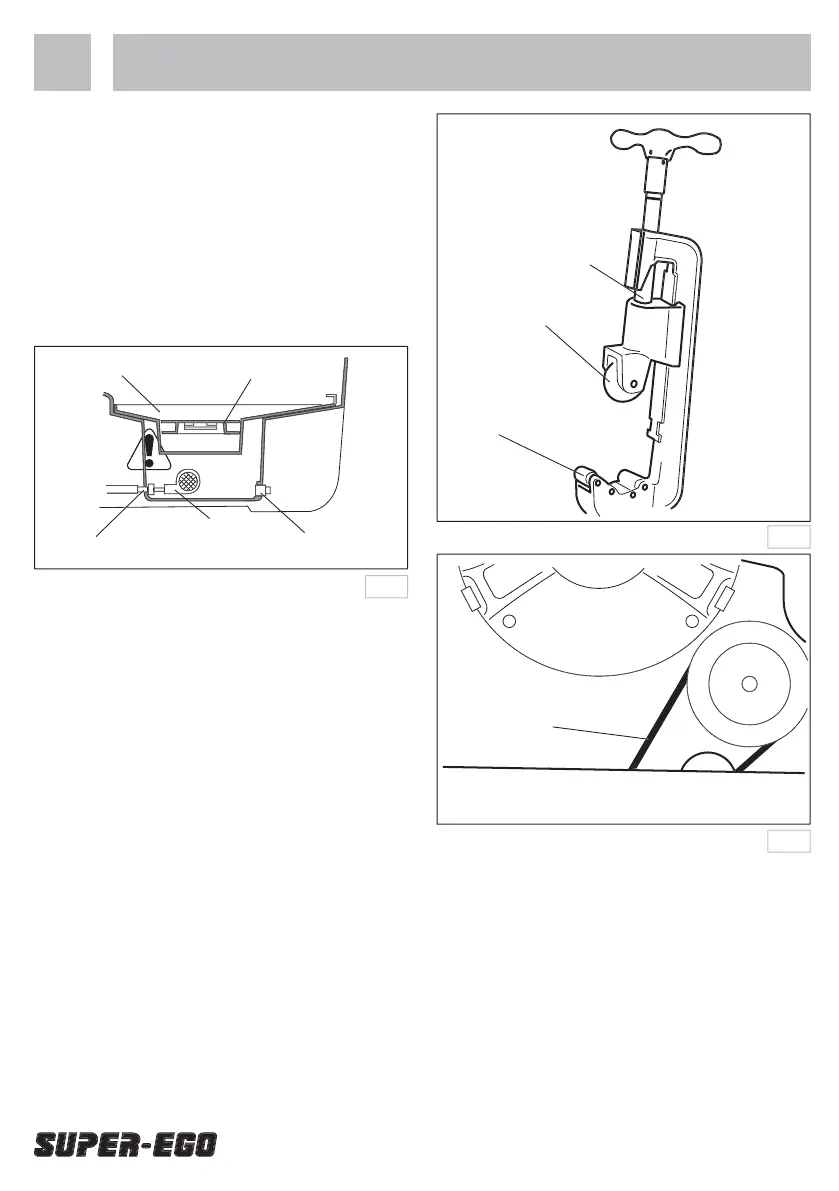

1. Make sure the oil fl ows freely. See that there is

enough oil in the tank and that all oil lines are free

2. If the oil becomes discoloured or contaminated,

drain the tank and refi ll with fresh cutting oil.

3. Clean the oil pot after every 8 to 12 hours of actual

4. When threads are cut, small chips of metal will fall

off and accumulate in the tank; effi cient cleaning is

therefore essential to ensure trouble-free operation.

Keeping the oil system clean

1. Drain the oil and check for contamination.

2. Remove and clean the scrap receiver, upper cover

of the tank, oil pot and strainer, and clean the oil

tank.If the oil system is kept clean, the working life

of the gear pump will be prolonged.

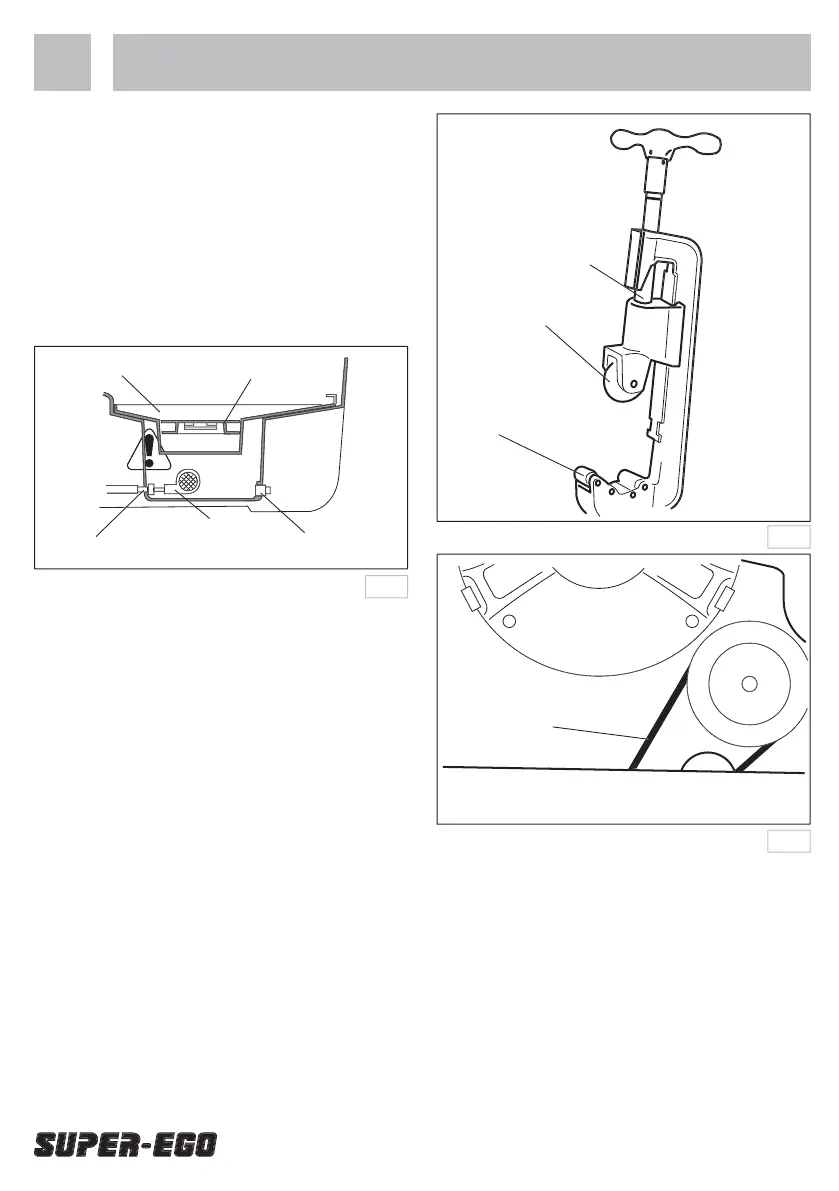

1. Check the cutter wheel and replace if blunt or damaged.

2. Check the alignment of the cutter frame feed

screw, roller pins and cutter pin.

3. Clean and lubricate the cutter wheel, cutter pin,

feed screw and cutter roller.

If the V-belt becomes slack, you can use the tension

pulley to adjust the tension. Never do this while the

power supply is connected. Always remove the plug

1. Remove the rear cover by undoing the 4 screws.

2. Slightly loosen the two head-cap screws and gently

force the tension pulley against the belt.

3. Retighten the two head-cap screws.

4. Replace the rear cover.

If the chuck jaw inserts show signifi cant wear or

damage, replace them all, not just one or two. Be sure

to line up the chuck jaw in the correct position on the

Oil line intake suction tube

Loading...

Loading...